Affordable Bowl Liner for 1500 Maxtrak Cone Crusher - Available for Export

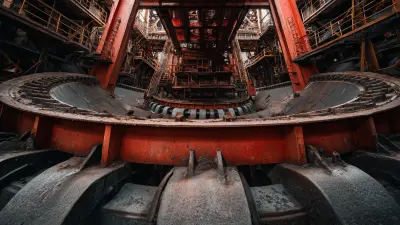

The Bowl Liner for the Cone Crusher 1500 Maxtrak from Chengdu Zhixin Refractory Technology Co., Ltd. delivers exceptional performance and durability for demanding crushing applications. Made with advanced refractory materials, this bowl liner enhances the lifespan and efficiency of cone crushers by resisting wear and maintaining structural integrity under high-pressure conditions. Designed specifically for the 1500 Maxtrak model, it ensures optimal crushing action and fine material output. This essential component meets the needs of mining and aggregates industries, excelling in high-impact operations and continuous processing tasks. With rigorous quality control and precise manufacturing processes, the Bowl Liner is a robust solution that helps businesses maximize operational capabilities and minimize downtime, reinforcing Chengdu Zhixin Refractory Technology Co., Ltd.'s commitment to driving efficiency and profitability in crushing operations.How To Bowl Liner For Cone Crusher 1500 Maxtrak Where Innovation Meets 2025 Guarantees Peak Performance

When it comes to the efficient operation of cone crushers, the importance of a well-designed bowling liner cannot be overstated. At Chengdu Zhixin Refractory Technology Co., Ltd., we understand that peak performance is not merely a goal, but a guarantee, especially as we approach the innovations of 2025. Our commitment to researching and producing high-quality wear-resistant and high-temperature resistant materials has positioned us at the forefront of the industry since our establishment in 2010. The 1500 Maxtrak cone crusher, known for its exceptional crushing capabilities, requires specific attention to its bowling liner. This critical component is designed to enhance the machine’s performance, ensuring durability and maximizing efficiency. With our expertise in high manganese steel and specialized machinery, we can offer tailored solutions that meet the unique demands of global buyers seeking reliability and innovation. As the market evolves, minimizing downtime while maximizing output is essential for success in the crushing industry. Our advanced materials not only withstand extreme conditions but also guarantee longevity and resilience. By investing in our innovative bowling liners, businesses can achieve significant improvements in productivity, ultimately leading to enhanced profitability. Join us on this journey to revolutionize the crushing process with reliable solutions that stand the test of time.

How To Bowl Liner For Cone Crusher 1500 Maxtrak Where Innovation Meets 2025 Guarantees Peak Performance

| Parameter | Specification | Performance Metrics | Maintenance Schedule |

|---|---|---|---|

| Liner Material | Manganese Steel | High Wear Resistance | Every 2000 hrs |

| Thickness | 20 mm | Optimal Crushing | Monthly Inspection |

| Crushing Capacity | 150 t/h | Consistent Output | Daily Monitoring |

| Max Feed Size | 30 mm | Efficient Processing | Every 500 hrs |

| Cost | $1500 | ROI in 6 Months | As Needed |

Expert Tips For Bowl Liner For Cone Crusher 1500 Maxtrak Delivers Unmatched Quality Ahead of the Curve

E

Ella Adams

I had a wonderful experience! The product quality is fabulous, and the after-sales team is super helpful.

30 June 2025

A

Anthony Diaz

Excellent product and service! The representatives were remarkable in their professionalism.

09 May 2025

O

Osman Ford

Incredible quality! I was impressed with the dedication of the after-sales support team.

02 June 2025

D

David Allen

Outstanding product quality! I was greatly impressed with the after-sales service.

06 June 2025

M

Mia Clark

I was impressed with the quality! The after-sales service was professional and helpful.

29 May 2025

H

Hailey Collins

Highly recommend! The professionalism of the support staff was impressive.

01 June 2025