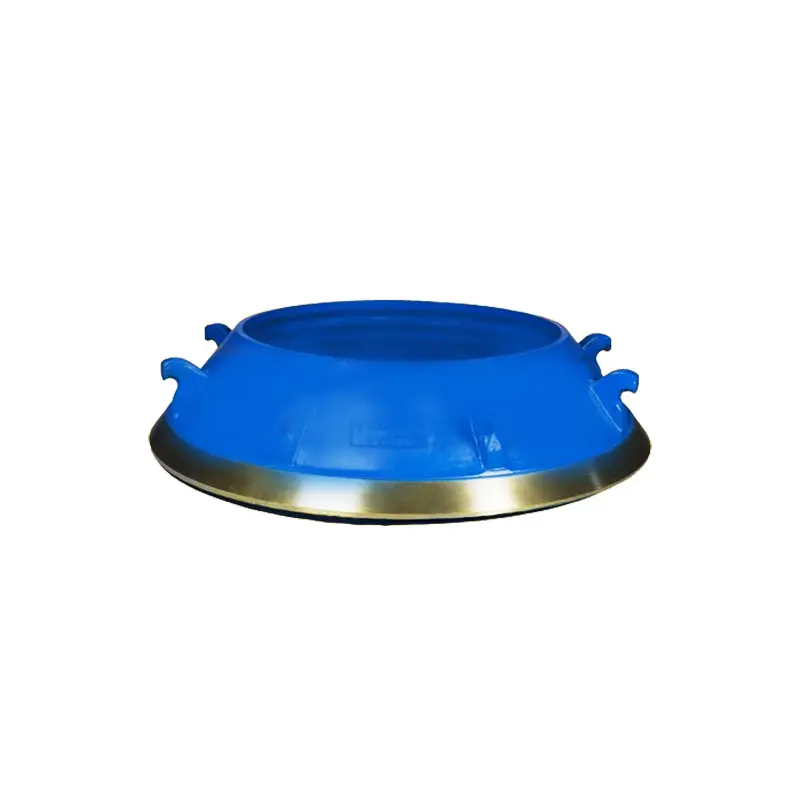

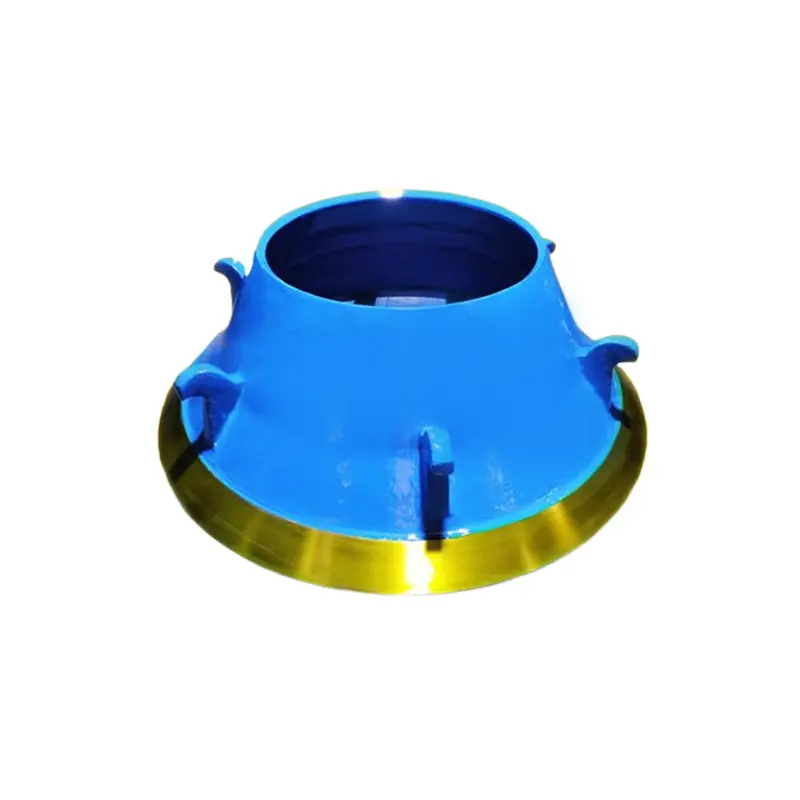

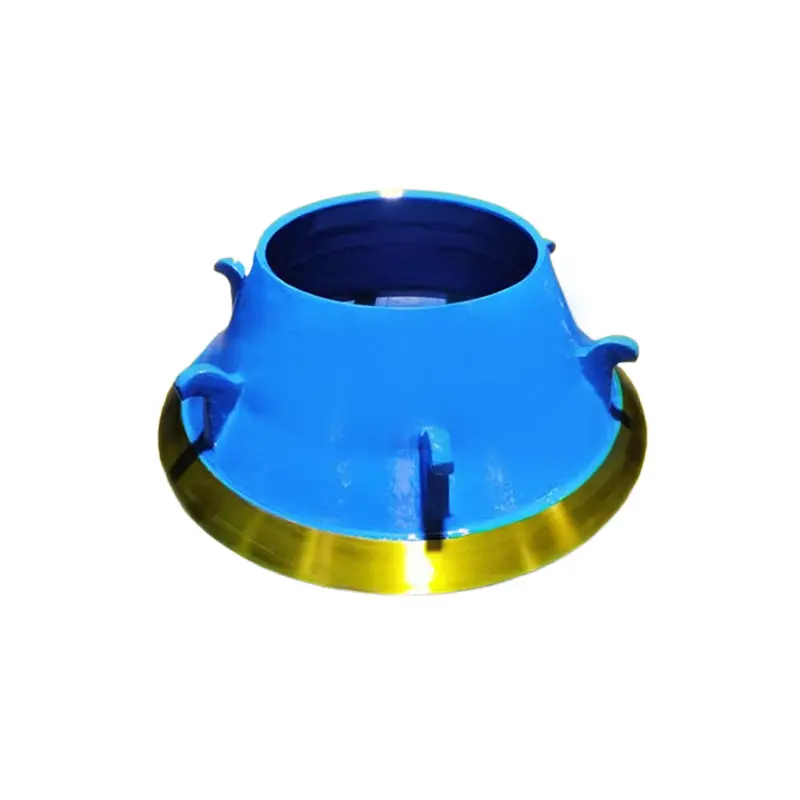

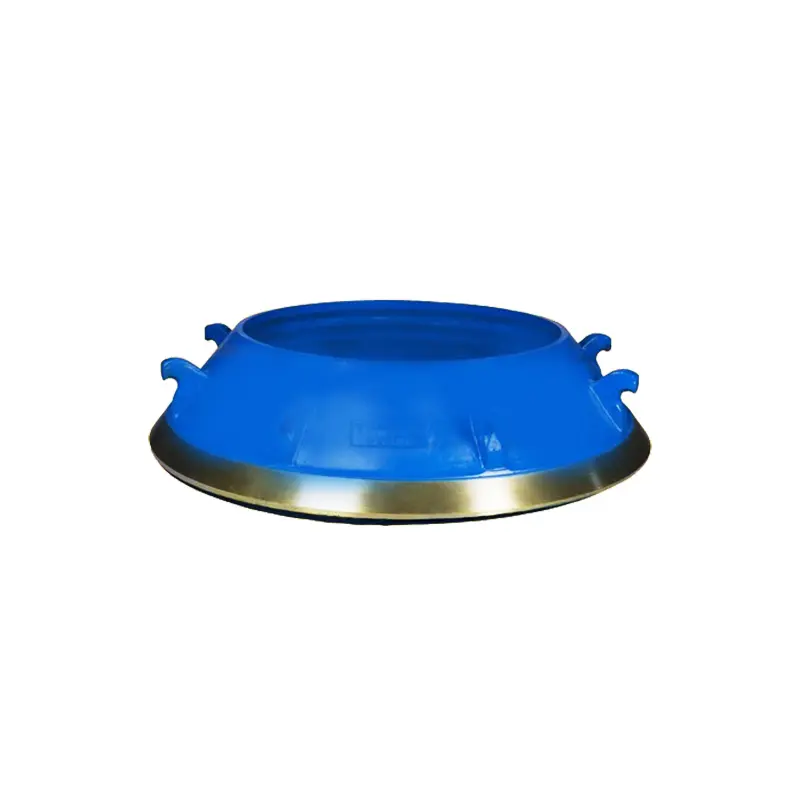

Bowl liner of cone crusher hydraulic spring type cone crusher wear parts

Product introduction

The concave and mantle are connected by casting zinc alloy, its firmness should be checked after the cone crusher has been running for a period of time. The connection between the concave and the adjustment ring is fixed by U-shaped fixing screws. Zinc alloy is cast between the concave and the adjustment ring to make them tightly combined.

The mantle can be replaced on site. Unscrew the adjusting screw sleeve installed on the upper frame (note that it should be rotated counterclockwise), remove the upper chamber hopper assembly, lift the adjusting screw sleeve with a lifting device, remove the adjusting screw sleeve support plate bolts, and then remove the concave for replacement. When assembling, clean the outer surface, apply butter on the thread surface of the adjusting screw sleeve, and install it in reverse order.

According to different cavities of concave and mantle, the crushing can be divided into three types: coarse crushing, medium crushing and fine crushing.

Product display

Why vchoose us?

Why vchoose us?

Chengdu Zhixin Refractory Technology is a technology-based enterprise integrating R&D, production, sales and empowerment. We are committed to providing one-stop services that save worry and cost for all crushing companies. The high-performance crusher wear-resistant parts we developed can increase the service life by more than 2 times, and we promise a full refund if it cannot be achieved.

Our crusher wear-resistant parts have been actually verified by countless users, which greatly reduces your comprehensive use cost and increases production and efficiency.

Working principle

The crushing process is completed by the eccentrically rotating crusher mantle and concave driven by the eccentric sleeve. The material enters the crushing chamber through the upper feed hopper, is discharged from the lower part after crushing, and is collected and discharged by the inlet and outlet hoppers. The crusher liners are the parts that directly "confront" the crushed materials, especially when crushing a lot of hard ores. Therefore, the quality and performance of the crusher wear parts are particularly important, which is related to the crushing efficiency and comprehensive cost.

Product Features

We can provide you with wear-resistant parts for multiple crushing equipment, such as Metso, Sandvik, Symmons, Dahongli, Sambo, etc. We will query the corresponding drawings from the database based on the equipment photos, nameplates, part numbers you provide, and produce them accurately.

2. Customized cavity type

As we all know, there are many different cavities between cone crusher liners. Even the same model of crusher usually has several different cavities for crushing ores or materials of different particle sizes. Although the crusher liner you are using cannot be changed, we can customize other cavities for you to meet your new crushing needs. The premise is that the installation size of the liner does not change.

3. Excellent Durability

The main feature of Chengdu Zhixin Refractory Technology's crusher wear-resistant parts is durability, and it is promised that the service life can reach more than twice that of conventional wear-resistant parts under the same working conditions.

4. Lower cost of use

Crusher wear parts are consumables and easily damaged. Therefore, when you choose a consumable with better performance and longer service life, you are naturally choosing to save money.

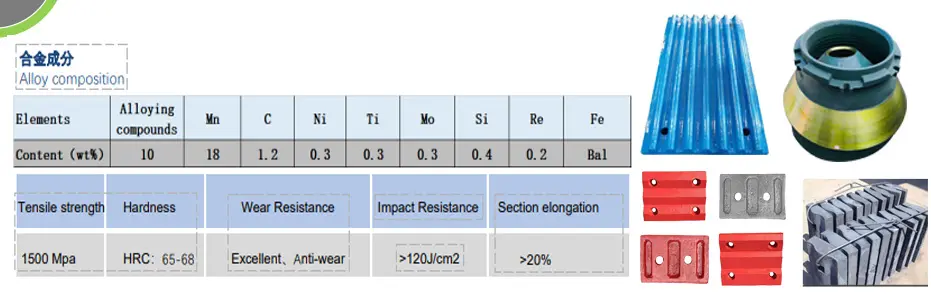

Please refer to the table below for our wear-resistant parts parameters, which are data certified by the Ministry of Science and Technology.