Affordable Cast Cone Crusher Parts from Reliable Factory Suppliers

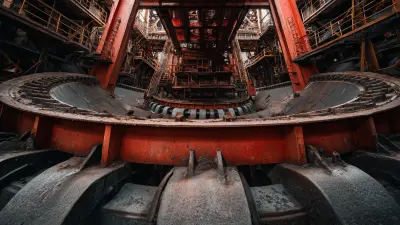

Chengdu Zhixin Refractory Technology Co., Ltd. specializes in high-quality cast cone crusher parts designed for superior durability and performance. Our products are rigorously engineered to meet the demanding needs of crushing applications across diverse sectors such as mining, construction, and recycling. Manufactured from premium materials and employing advanced techniques, our cone crusher components boast exceptional wear resistance, significantly prolonging the lifespan of your equipment. Our extensive selection includes mantles, bowls, and liners, ensuring compatibility with various cone crusher models. Committed to quality and customer satisfaction, we offer customized solutions tailored to meet your specific requirements. Our experienced team is always available to help you select the right components for optimal performance, ensuring your operations run smoothly and efficiently. Trust Chengdu Zhixin Refractory Technology Co., Ltd. for reliable cast cone crusher parts that enhance your productivity.Quick Tips To Cast Cone Crusher Parts Stands Out Your End-to-End Solution

In the ever-evolving landscape of the mining and construction industry, the efficiency and longevity of machinery are paramount. Chengdu Zhixin Refractory Technology Co., Ltd., established in 2010, specializes in developing and producing high-quality wear-resistant and high-temperature resistant materials, along with high manganese steel components for machinery. Among these products, our cone crusher parts stand out as essential components to enhance durability and performance in crushing operations. Our quick tips for selecting and utilizing cone crusher parts reflect our commitment to providing end-to-end solutions for global buyers. First, prioritize sourcing parts made from high manganese steel, which offers exceptional impact resistance and toughness. This material is designed to withstand the wear and tear of heavy-duty operations, ensuring prolonged lifespan and reducing downtime. Furthermore, consider the design specifications and compatibility of the parts with your existing machinery to optimize functionality and efficiency. Lastly, engaging with a reliable supplier like Chengdu Zhixin guarantees not only quality products but also technical support and expertise in wear-resistant materials. Our commitment to innovation and research ensures that our products meet the highest industry standards, ultimately contributing to your operational success. Choose cone crusher parts that redefine reliability and performance, and experience the difference in your end-to-end solution.

Quick Tips To Cast Cone Crusher Parts Stands Out Your End-to-End Solution

| Tip | Description | Benefits | Implementation Steps |

|---|---|---|---|

| Material Selection | Choose high-quality alloys for durability. | Increased lifespan of parts. | Research materials; test samples. |

| Manufacturing Precision | Use advanced machinery for precise casting. | Reduces errors and improves quality. | Invest in CNC machines; train staff. |

| Regular Inspections | Conduct routine checks during production. | Identifies defects early; saves costs. | Schedule inspections; document results. |

| Heat Treatment | Apply heat treatment to enhance strength. | Improves resistance to wear. | Set parameters; monitor results. |

| Quality Control | Implement a robust quality control system. | Ensures all parts meet specifications. | Create quality benchmarks; train inspectors. |

Effective Ways To Cast Cone Crusher Parts Products Exceeds Industry Benchmarks

S

Sophia Harris

Outstanding product quality combined with professional customer care. Highly recommend!

10 May 2025

A

Ava Nelson

The product quality is amazing! Customer support was efficient and incredibly friendly.

28 June 2025

S

Sophie Brooks

Highly impressed with the product! The after-sales support team exceeded my expectations.

19 May 2025

H

Henry Long

Fantastic quality and a wonderful after-sales experience. The team is incredibly knowledgeable.

14 May 2025

S

Samantha Nguyen

Outstanding quality! Their support team was efficient and very responsive.

05 July 2025

M

Madison Martinez

Fantastic product! I appreciated the thorough follow-up from the support team.

21 June 2025