High-Quality CH420 Cone Crusher Mantle Liners | OEM Parts Supplier

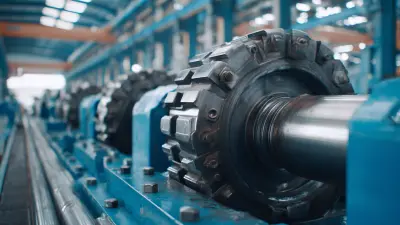

The CH420 Cone Crusher Wear Parts Mantle Liners are specifically designed to provide exceptional durability and high performance in demanding crushing environments. Crafted for the CH420 model, these liners ensure optimal wear resistance while maintaining the shape of the crushed material, thus promoting efficient processing and reducing downtime. Manufactured by Chengdu Zhixin Refractory Technology Co., Ltd., these wear parts utilize advanced techniques and premium materials, enhancing precision and longevity. By minimizing the need for frequent replacements, they contribute to lower operational costs. Suitable for a variety of materials, these liners serve diverse industries, including mining and construction. Count on our commitment to quality and performance with CH420 Cone Crusher Mantle Liners for a reliable solution that boosts your crushing operations. Enjoy increased efficiency and an extended service life with our premium products.7 Key Tips To Ch420 Cone Crusher Wear Parts Mantle Liners Products Ahead of the Curve

In the competitive landscape of mining and aggregate processing, understanding the maintenance and longevity of your machinery is crucial. Chengdu Zhixin Refractory Technology Co., Ltd., established in 2010, specializes in manufacturing high-quality wear-resistant materials and high manganese steel components. Among our standout products are the Ch420 cone crusher wear parts, specifically the mantle liners, designed to offer superior performance and durability. To stay ahead of the curve, global buyers should consider seven essential tips when selecting and maintaining Ch420 cone crusher mantle liners. First, prioritize sourcing from reputable manufacturers like Chengdu Zhixin, known for innovation and rigorous quality control. Second, regularly inspect wear parts to identify signs of wear and tear early, ensuring timely replacement to minimize downtime. Third, choose materials specifically designed for high-impact and abrasive applications to enhance the life expectancy of your equipment. In addition, understanding the operational parameters of your crusher, such as moisture content and feed size, can significantly influence the wear rates of the mantle liners. Utilizing advanced technologies and materials, like those developed by our team, can optimize performance and efficiency. Lastly, collaborating closely with suppliers for maintenance recommendations and support will ensure that your machinery operates at peak efficiency, ultimately improving productivity and reducing overall operational costs. Investing in quality wear parts is not just a purchase—it's a strategic move towards sustained success in your industry.

7 Key Tips To Ch420 Cone Crusher Wear Parts Mantle Liners Products Ahead of the Curve

| Tip Number | Tip Description | Frequency of Maintenance | Expected Lifespan (Hours) | Replacement Parts |

|---|---|---|---|---|

| 1 | Regular Inspections | Monthly | 500 | Mantle Liner |

| 2 | Proper Lubrication | Weekly | 800 | Bearing |

| 3 | Check Alignment | Quarterly | 1000 | Adjustment Tool |

| 4 | Monitor Wear Patterns | Biannually | 700 | Liner Profile |

| 5 | Upgrade Components | Annually | 1200 | High-Quality Liners |

| 6 | Dust Suppression | As Needed | 1500 | Spray System |

| 7 | Staff Training | Yearly | N/A | Training Materials |

Simple Ways To Ch420 Cone Crusher Wear Parts Mantle Liners More Than a Supplier - A Partner in 2025

S

Sophia Harris

Outstanding product quality combined with professional customer care. Highly recommend!

10 May 2025

C

Christopher Anderson

Very satisfied with my purchase! The customer service team displayed exceptional professionalism.

01 June 2025

L

Lucas Peterson

Quality is exceptional, and the after-sales service team was a pleasure to work with.

01 June 2025

L

Logan Turner

Exceptional product quality backed by outstanding support. Very impressed!

28 June 2025

D

David Allen

Outstanding product quality! I was greatly impressed with the after-sales service.

06 June 2025

K

Katherine Allen

Fantastic service! The quality of the product is matched only by their excellent support.

21 June 2025