High-Quality OEM ODM CH440 Cone Crusher Parts from Reliable Exporters

Chengdu Zhixin Refractory Technology Co., Ltd. offers the Ch440 Cone Crusher Parts designed for exceptional durability and performance in mining and aggregate operations. Custom-engineered to fit the Sandvik CH440 model, these components are built to endure demanding crushing applications, ensuring optimal efficiency and reducing downtime. With a commitment to high-quality materials and precision manufacturing, our cone crusher parts provide excellent wear resistance and reliable operation in tough environments. The innovative design and advanced metallurgy enhance the functionality and extend the lifespan of your equipment. Clients benefit from our superior customer service and customized solutions tailored to their specific requirements. Whether you need replacement parts or maintenance components, the Chengdu Zhixin team is dedicated to helping you achieve peak performance in your operations.

10 Essential Tips For Ch440 Cone Crusher Parts Application Factory

When it comes to ensuring optimal performance and longevity of CH440 cone crushers, understanding the application and handling of essential parts is crucial. Chengdu Zhixin Refractory Technology Co., Ltd., established in 2010, specializes in high-quality, wear-resistant materials and high manganese steel components designed specifically for heavy machinery. Here are ten essential tips to enhance the effectiveness of your CH440 cone crusher parts in various operational settings. Firstly, regular inspection and maintenance of wear parts, such as the mantle and Bowl Liner, will significantly reduce wear and tear, preventing costly downtime. It's essential to select parts made from high-quality materials, like those produced by Zhixin, which offer superior resistance to high temperatures and abrasion. Secondly, ensure that the cone crusher is operated within the recommended parameters, as exceeding these limits can lead to premature failure of critical components. Thirdly, keep the feed material consistent in size and quality to minimize excess strain on the crusher, which can affect the life span of the wear parts. Moreover, consider dust management practices, as excessive dust can lead to equipment wear and performance issues. Utilizing proper lubrication systems also plays a vital role in maintaining the efficiency and reliability of the cone crusher. Lastly, staying updated on industry innovations and practices in wear-resistant materials can help you make informed decisions about the parts you choose, ensuring that your machinery runs smoothly and efficiently for years to come. With the commitment to quality and innovation at Chengdu Zhixin, you can trust that our parts will meet your operational needs and exceed expectations.

10 Essential Tips For CH440 Cone Crusher Parts Application Factory

| Tip Number | Tip Description | Importance Level | Expected Outcome |

|---|---|---|---|

| 1 | Regular maintenance to ensure optimal performance. | High | Reduced downtime and extended lifespan. |

| 2 | Use genuine replacement parts to maintain quality. | High | Improved reliability and performance. |

| 3 | Ensure correct oil levels for lubrication. | Medium | Smooth operation and reduced wear. |

| 4 | Regularly check for signs of wear. | Medium | Proactive replacement and minimal downtime. |

| 5 | Adhere to operational guidelines for load limits. | High | Prevention of damage and efficient operation. |

| 6 | Inspect belts and hoses routinely for integrity. | Medium | Preventative measures against failures. |

| 7 | Train operators on best practices and safety procedures. | High | Higher safety and operational efficiency. |

| 8 | Monitor vibration levels to detect issues early. | Medium | Early fault detection and corrective actions. |

| 9 | Ensure proper crusher settings for material specifications. | High | Maximized efficiency and reduced waste. |

| 10 | Keep a detailed log of maintenance and repairs. | Medium | Facilitates future maintenance and issue tracking. |

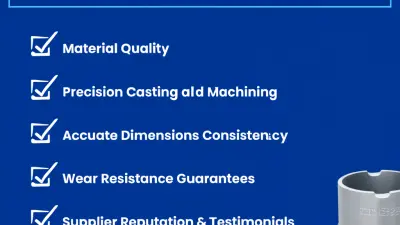

Why Ch440 Cone Crusher Parts Where Service Meets Innovation Guarantees Peak Performance

D

Daniel Martinez

The quality speaks for itself! Their sales support team was very patient and informative.

06 June 2025

O

Olivia Martinez

Fantastic quality! The after-sales service was timely and very knowledgeable.

27 June 2025

O

Oliver Collins

I am very impressed! The quality is unmatched and the customer care team was very informative.

21 May 2025

A

Abigail Stewart

Excellent purchase experience! Their post-sale support was patient and remarkably helpful.

11 May 2025

E

Elijah Sanchez

The product quality is outstanding! I was particularly impressed by the after-sales support.

24 May 2025

S

Sebastian Murphy

Impressive quality and phenomenal customer service. The after-sale team is very knowledgeable.

06 July 2025