Manufacturer of cone crusher wear-resistant parts

Working principle

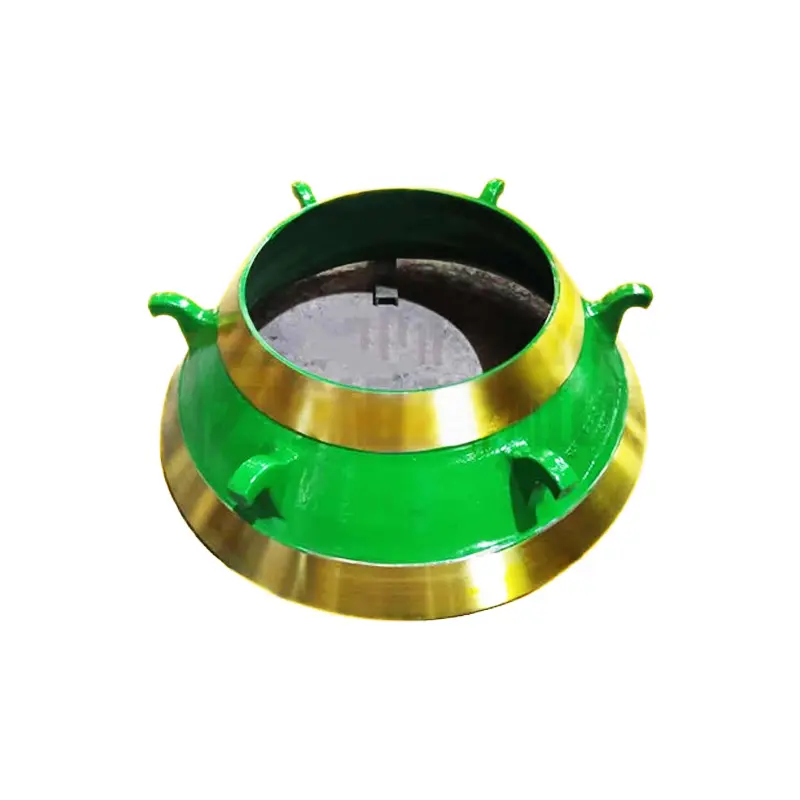

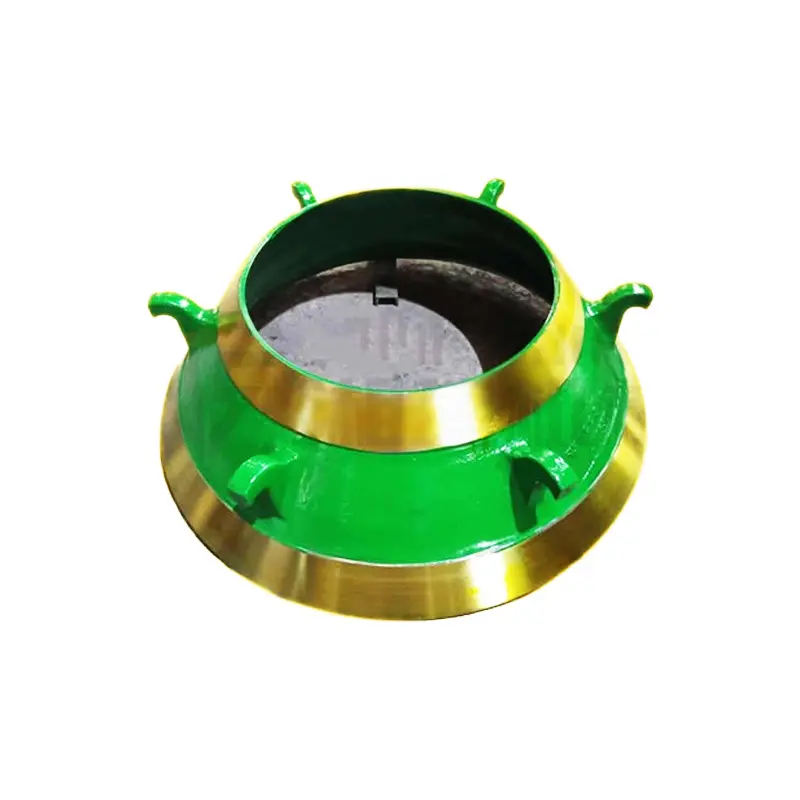

When the machine is working, the movable cone of the crusher (cone crusher mantle) performs a swinging motion around a fixed point, so that the mantle of the cone crusher and the crushing wall of the fixed cone (cone crusher concave) are sometimes close to and sometimes away from each other, so that the ore is continuously impacted, squeezed and bent in the crushing chamber to achieve ore crushing, complete crushing and discharge.

The structure of the equipment includes a motor, a pulley or a coupling, a transmission shaft, a set of cone liner, etc. The motor drives the eccentric sleeve to rotate through the bevel gear, so that the crushing cone moves in a swiveling motion. The connection between the support sleeve and the frame is pressed by a spring. When an unbreakable object such as a metal block falls into the crusher, the spring is compressed and deformed, and foreign matter is discharged to prevent damage to the machine.

The application field of the cone crusher is very wide, and it is suitable for raw material crushing in industries such as metallurgy, construction, road construction, chemistry and silicate. It has a large crushing ratio, high efficiency, low energy consumption, and uniform product particle size. It is suitable for medium and fine crushing of various ores and rocks. Therefore, cone crusher lining is a consumable part/consumable material, which is widely in demand. At the same time, it is also very important to select high-performance and longer-life cone crusher wear-resistant parts.

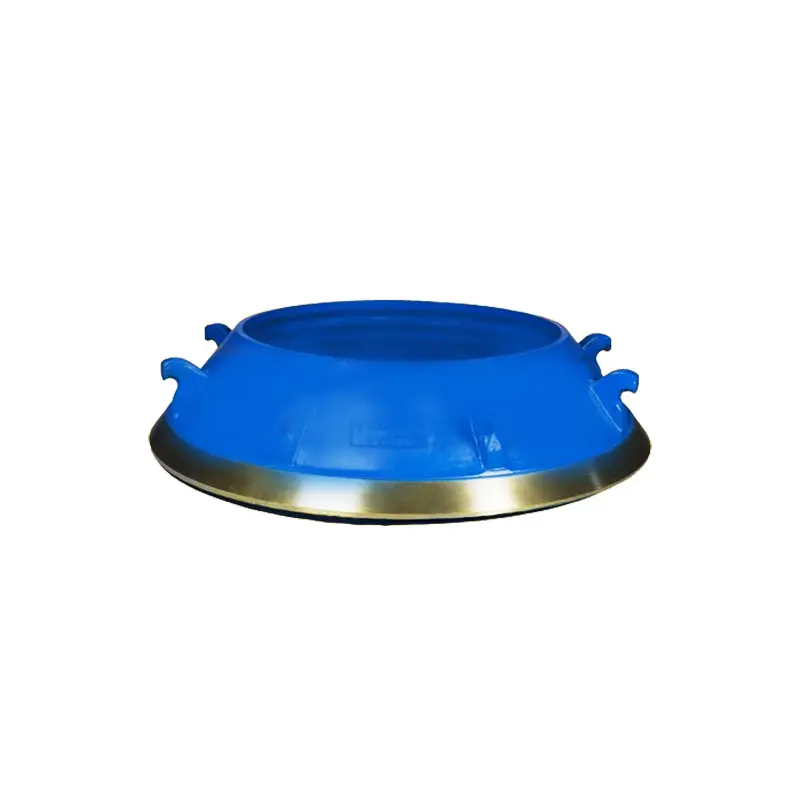

Product display

Main Features

2) Wide range of products: We provide a full range of crusher wear parts for kinds of brands, such as Metso, Sandvik, Symmons, Telsmith, Sambo, Minyu etc.

4)Wide range of wear parts: jaw plate, cone crusher liner, hammer, compound steel plate, ball mill liner, etc.