Affordable Concave Mantle for Cone Crusher - Factory Direct from Manufacturers

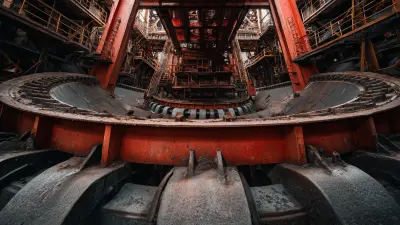

The Concave Mantle for Cone Crusher is a crucial part designed to optimize the performance and longevity of your crushing machinery. Crafted by Chengdu Zhixin Refractory Technology Co., Ltd., this component is made from high-quality materials, offering outstanding wear resistance and functionality. Its advanced design enhances crushing efficiency, making it suitable for a variety of mining and aggregate operations. With precise dimensions and compatibility across multiple cone crusher models, the Concave Mantle ensures a perfect fit and superior performance. This product not only extends the life of the cone crusher but also minimizes operational downtime, leading to enhanced productivity and cost efficiency. Chengdu Zhixin Refractory Technology Co., Ltd. is dedicated to providing high-performance components that meet the evolving demands of the industry. Rely on their expertise to boost your crushing operations with dependable solutions like the Concave Mantle, designed for exceptional effectiveness.How To Select Concave Mantle For Cone Crusher Guarantees Peak Performance Pioneers in the Field

Selecting the right concave mantle for your cone crusher is crucial for maximizing operational efficiency and ensuring long-term performance. As a leader in the manufacturing of high-quality wear-resistant materials, Chengdu Zhixin Refractory Technology Co., Ltd. has been at the forefront of innovation since our establishment in 2010. Our expertise in high manganese steel and refractory materials positions us uniquely in the market to support your machinery needs with precision and reliability. When evaluating concave mantles, several factors must be taken into account to guarantee peak performance. First, consider the material composition; high manganese steel offers superior toughness and resistance to wear, which can significantly extend the lifecycle of your components. Second, the design of the concave mantle should align with your specific crushing requirements. An optimal design maximizes the crushing force and improves the efficiency of material throughput, which is essential for meeting production targets. Furthermore, understanding the operational environment will guide you in selecting the most suitable concave mantle. High-temperature or abrasive materials require specialized solutions that we at Chengdu Zhixin can provide. Our commitment to research and development ensures that our products not only meet but exceed industry standards. Collaborating with us means that you are investing in durable, high-performing materials that enhance your operational output while reducing downtime. Whether you are a global buyer in the mining, construction, or recycling sectors, we stand ready to meet your needs with unparalleled quality and service.

How To Select Concave Mantle For Cone Crusher Guarantees Peak Performance Pioneers in the Field

| Parameter | Description | Importance |

|---|---|---|

| Material Type | Grade of the material used for concave mantle. | Critical for wear resistance and longevity. |

| Profile | The shape and dimensions of the concave mantle. | Affects crushing efficiency and product size. |

| Thickness | Thickness of the mantle material. | Influences strength and durability. |

| Compatibility | Match with existing crusher models. | Ensures optimal fitting and performance. |

| Manufacturer | Reputation and history of the manufacturer. | Affects reliability and quality of the product. |

| Cost | Price of the concave mantle. | Impacts budget but should not compromise quality. |

How To Pick The Right Concave Mantle For Cone Crusher Where Innovation Meets 2025 Global Reach

D

David Johnson

Great product and even better service! The representatives are knowledgeable and professional.

13 May 2025

B

Benjamin Clark

Truly impressed with the product’s durability. The staff’s dedication to customer service is noteworthy.

28 June 2025

G

Grace Gonzalez

Exceedingly satisfied with my purchase! Their customer support team is professional and very helpful.

09 May 2025

O

Osman Ford

Incredible quality! I was impressed with the dedication of the after-sales support team.

02 June 2025

J

Julia Morgan

The quality is outstanding! I was particularly impressed with the efficient after-sales service.

07 July 2025

H

Hailey Collins

Highly recommend! The professionalism of the support staff was impressive.

01 June 2025