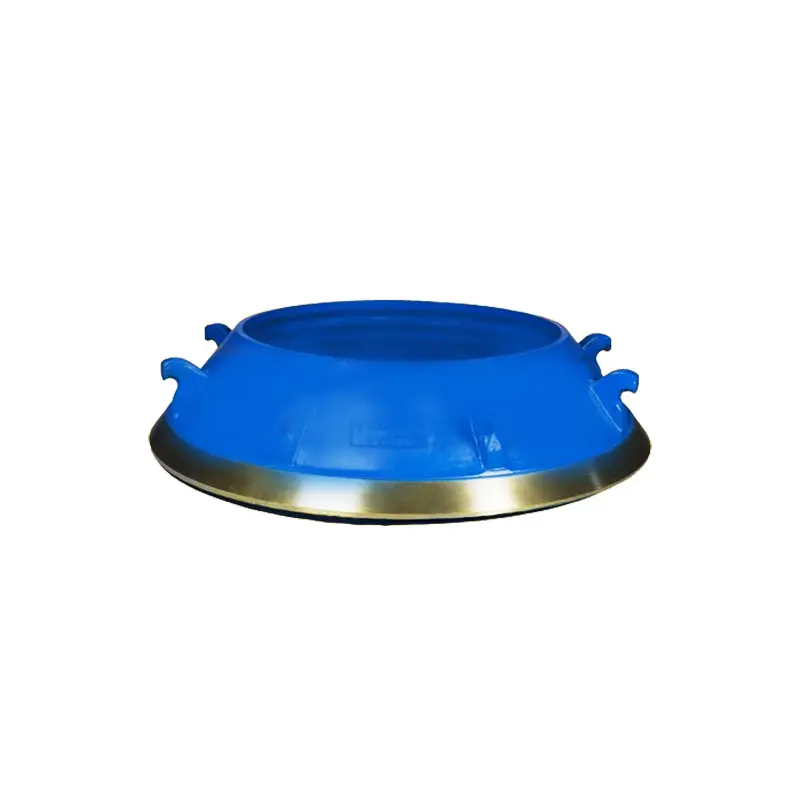

Manganese steel concave and mantle for mining crushers

Working principle of cone crusher

The cone crusher liner is a key component of the crushing equipment. Its main function is to protect the cylinder, adjust the material crushing efficiency and extend the life of the equipment.

Traditional materials include high manganese steel, modified high manganese steel and carbon alloy steel. Modern technology mostly uses manganese steel containing more than 13% manganese to improve surface hardening and wear resistance. Material selection needs to be combined with factors such as material hardness, particle size distribution and humidity: short liner for hard materials, long liner for soft materials; short liner for fine materials, long liner for coarse materials.

Product display

What we can do for you.

What we can do for you.

We provide customized crusher wear parts service, no matter which crusher brand, whether it is spring type, hydraulic type, single cylinder, multi-cylinder, etc. We can provide you with high-performance and long-life crusher lining.

You only need to provide the nameplate of the machine, the overall photo, and the wear part number, and we will find the corresponding drawings and confirm with you.

Product features

Compared with general products on the market, our company's crusher wear parts have 2-3x longer service life. Which will help your company to save comprehensive cost.

Our crusher wear-resistant parts are based on high manganese steel, melted with our developed high-crystalline nano alloy. The shape is somewhat similar to the titanium carbide rod process on the market, but our performance is better.

Why? Because the shrinkage ratio of titanium carbide rods on the market is quite different from that of high manganese steel, which often causes a gap between the two products, thus affecting product quality. Another thing is that titanium carbide on the market often protrudes from the surface of wear-resistant parts. Our alloy is made through at least 4 chemical processes and can be perfectly integrated with high manganese steel. Not only is there no gap between high manganese steel and chemical nails, but the chemical nails are also hidden inside the wear-resistant parts, making them both beautiful and durable.

Why choose us

1. Certified by the Ministry of Science and Technology, leading product performance.

2. Full-process supervision of the smart manufacturing ecosystem, reliable quality.

3. Full refund if the promise is not met!