Affordable CH440 Cone Crusher Spare Parts - Factory Direct Exporter Solutions

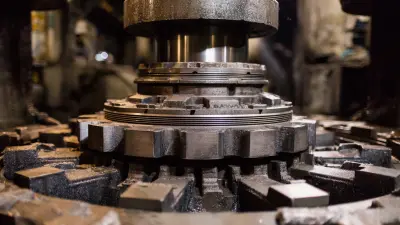

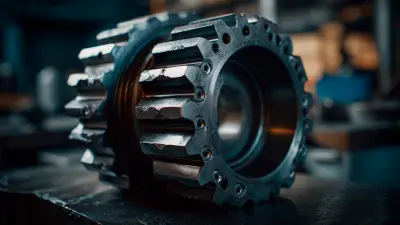

The CH440 Cone Crusher is crucial for efficient crushing operations, making the availability of high-quality spare parts essential for optimal performance. Chengdu Zhixin Refractory Technology Co., Ltd. specializes in premium spare parts designed specifically for the CH440 model. Our components ensure peak efficiency of your crusher, minimizing downtime and maintenance costs. Crafted from durable materials, each part meets stringent quality standards for longevity and reliability. Our extensive inventory includes vital elements like liners, mantles, and other essential components, all aimed at enhancing the functionality of your crusher. By choosing our spare parts, you invest in the durability of your equipment and ensure consistent performance throughout every crushing cycle. Trust Chengdu Zhixin Refractory Technology Co., Ltd. for the reliability and quality your operations need to maximize productivity and profitability.Best Strategies For Cone Crusher Ch440 Spare Parts Crusher Dominates Application

In the competitive landscape of industrial machinery, ensuring optimal performance and longevity of equipment is crucial. At Chengdu Zhixin Refractory Technology Co., Ltd., established in 2010, we specialize in the research and production of high-quality wear-resistant, high-temperature resistant materials, as well as high manganese steel components essential for the efficient functioning of cone crushers, specifically the CH440 model. The CH440 cone crusher is renowned for its versatility and reliability, making it a preferred choice across various industries. To maximize its operational efficiency, understanding the best strategies for sourcing spare parts is vital. Firstly, choosing high-quality components ensures minimal downtime, reducing maintenance costs and extending the lifespan of the machinery. Our spare parts are designed to meet and exceed OEM specifications, providing unparalleled fit and performance. Secondly, establishing a streamlined supply chain can enhance procurement efficiency. By collaborating with reliable manufacturers like Chengdu Zhixin, global buyers can ensure competitive pricing and prompt delivery times, which are critical in maintaining operational continuity. Moreover, a proactive maintenance strategy involving regular inspections and timely replacement of spare parts can enhance the crusher’s performance, ultimately leading to increased productivity. Investing in durable and cost-effective spare parts from our company ensures your CH440 cone crusher operates at its best, making it an invaluable asset in your production line. With our expertise in high manganese steel and specialist materials, we are committed to supporting global purchasers with tailored solutions to meet their unique operational demands.

Best Strategies For Cone Crusher CH440 Spare Parts Crusher Dominates Application

| Spare Part | Material Used | Wear Life (Hours) | Cost ($) | Application Area |

|---|---|---|---|---|

| Mantle | Manganese Steel | 200 - 300 | 800 | Secondary Crushing |

| Concave | Manganese Steel | 300 - 400 | 700 | Primary Crushing |

| Spider Bushing | Bronze | 1500 - 2000 | 250 | Support Structure |

| Main Shaft | Alloy Steel | 2000 - 2500 | 1200 | Drive Assembly |

| Drive Belt | Rubber | 1000 - 1500 | 300 | Power Transmission |

Key Steps to Choosing Cone Crusher Ch440 Spare Parts Crusher Ahead of the Curve Products

M

Michael Thompson

The quality of the product exceeded my expectations. The support team was incredibly responsive and helpful throughout the purchasing process.

26 May 2025

M

Megan Thomas

Top-quality product with a responsive support team. They made the whole experience seamless!

05 June 2025

K

Kyle Evans

I am very pleased with my purchase! Their supportive staff made all the difference.

17 June 2025

C

Chloe Sanchez

Unmatched quality and service! The post-purchase support exceeded my expectations.

13 June 2025

H

Hailey Collins

Highly recommend! The professionalism of the support staff was impressive.

01 June 2025

A

Arianna Brooks

This product stands out in quality! The service team was remarkably professional.

21 June 2025