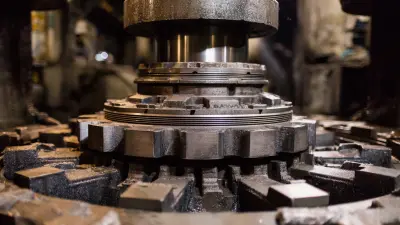

OEM High-Performance Cone Crusher Feed Cone Suppliers & Exporters

The Cone Crusher Feed Cone from Chengdu Zhixin Refractory Technology Co., Ltd. is designed for high performance in challenging crushing environments. Constructed from premium materials, this component offers exceptional durability and wear resistance, thereby extending the lifespan of your equipment. With its precisely contoured shape, the feed cone optimizes material flow into the crushing chamber, enhancing efficiency and reducing operational costs. Its robust design accommodates a wide range of feed materials, ensuring consistent and high-quality output. Utilizing advanced manufacturing techniques, Chengdu Zhixin Refractory Technology Co., Ltd. produces feed cones that adhere to stringent industry standards. Our focus on innovation and quality makes our products a trusted choice for operators in multiple sectors. Upgrade your cone crusher with our reliable feed cone for outstanding performance in the toughest conditions. Choose Chengdu Zhixin for solutions that boost your production capacity.Simple Ways To Cone Crusher Feed Cone Service Backed by Expertise Now Trending

In the ever-evolving world of industrial machinery, ensuring the optimal performance of your cone crushers is crucial for maximizing productivity and profitability. At Chengdu Zhixin Refractory Technology Co., Ltd., established in 2010, we specialize in developing high-quality wear-resistant and high-temperature resistant materials, specifically designed for the high manganese steel industry. Our team's extensive expertise enables us to provide simple yet effective solutions for cone crusher feed maintenance, ensuring reliable service backed by years of research and innovation. One of the key aspects of enhancing the durability and efficiency of your cone crusher is proper feeding techniques. Using the right feed materials and adhering to optimal feeding practices can significantly reduce wear and tear on the machinery, improving both output and lifespan. Our specially formulated wear-resistant materials can withstand the rigors of high-temperature environments, guaranteeing your cone crushers operate at peak performance while reducing the risk of unplanned downtime. As the global market for cone crushers continues to expand, our commitment to quality and excellence remains paramount. By partnering with Chengdu Zhixin Refractory Technology Co., Ltd., you gain access to a wealth of knowledge and advanced materials that streamline your operations. Let us help you meet your production goals with our cutting-edge solutions tailored to today's industrial needs. Experience the benefits of our expertise—make your cone crushers more efficient and reliable with us.

Simple Ways To Cone Crusher Feed Cone Service Backed by Expertise Now Trending

| Service Type | Description | Frequency | Expertise Level | Cost (USD) |

|---|---|---|---|---|

| Regular Inspection | Routine checks for wear and tear on the cone. | Monthly | Medium | 200 |

| Lubrication | Applying grease to moving parts to reduce friction. | Weekly | Low | 50 |

| Wear Part Replacement | Replacing old parts to maintain performance. | As Needed | High | 1200 |

| Training | Training staff on operational best practices. | Quarterly | Expert | 800 |

| Performance Analysis | Analyzing operational data to optimize efficiency. | Bi-Annual | High | 300 |

Where the Value Lies Cone Crusher Feed Cone Guarantees Peak Performance Trusted by Pros

J

Jonathan White

Exceptional product quality! It’s clear that they stand behind their product with a strong after-sales service.

19 May 2025

W

William Miller

It’s rare to find such a quality product accompanied by fantastic customer support. Truly a great investment.

20 May 2025

M

Madison Allen

This product is a must-have! The customer service exceeded my expectations in terms of response time.

24 June 2025

J

Jack Young

Quality and service were both excellent. The team was very professional and knowledgeable.

09 May 2025

S

Sophie Brooks

Highly impressed with the product! The after-sales support team exceeded my expectations.

19 May 2025

O

Oliver Young

The quality is exceptional! The customer service team is knowledgeable and professional.

19 June 2025