Wholesale Granite Cone Crushers | Reliable Supplier & Factory Options Available

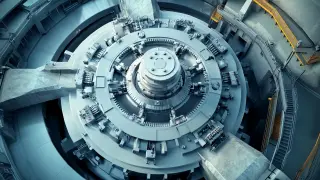

The Cone Crusher, designed by Chengdu Zhixin Refractory Technology Co., Ltd., is a high-performance machine specifically engineered for efficiently crushing granite. Built for high-volume production, this robust crusher delivers exceptional durability even under the most challenging conditions. Its advanced crushing technology produces a uniform and fine output, ideal for aggregates used in construction and industrial applications. Featuring a powerful motor and innovative hydraulic systems, the cone crusher effectively manages hard materials like granite, helping to reduce downtime and increase productivity. The user-friendly design facilitates easy maintenance, allowing operators to concentrate on maximizing output. Equipped with integrated safety features, this equipment ensures optimal protection for both operators and machinery. Chengdu Zhixin Refractory Technology Co., Ltd. is committed to delivering quality and reliability, reinforcing its position as a leader in the quarry and mining industry.Tips & Tricks for Cone Crusher For Crushing Granite Outperforms the Competition Dominates

When it comes to crushing granite, the right equipment can make all the difference. Chengdu Zhixin Refractory Technology Co., Ltd., established in 2010, specializes in producing high-quality, wear-resistant materials and high manganese steel machinery that stand up to the toughest tasks. Our cone crushers are engineered to outperform the competition, ensuring efficient and reliable operations in your quarry or construction site. To maximize the efficiency of your cone crusher when processing granite, consider these tips and tricks. First, ensure that the feed material is uniformly distributed into the crushing chamber. This helps optimize the crushing process and reduces wear on the equipment. Next, regularly monitor the cavity level, maintaining an adequate level to enhance throughput while minimizing operational costs. Additionally, selecting the right crushing liners is crucial; high manganese steel options from Zhixin provide exceptional resistance to wear and tear, prolonging the life of your machinery. At Chengdu Zhixin, we understand the challenges faced in the industry and continuously strive to improve our products. Our expertise in high-temperature resistant materials allows us to create robust solutions tailored for your specific needs. By choosing our cone crushers, you're not just investing in equipment—you're ensuring efficient, durable performance that keeps you ahead of the competition. Whether you're a global procurement manager or a local contractor, let us help you dominate your crushing operations.

Tips & Tricks for Cone Crusher For Crushing Granite Outperforms the Competition Dominates

| Feature | Description | Performance Metric | Tip |

|---|---|---|---|

| Crushing Chamber Design | Optimized for maximum throughput and material reduction. | Higher Production Rate | Choose the correct chamber profile for your material. |

| Adjustment Mechanism | Allows for quick setting adjustment to suit varying feed sizes. | Flexibility in Operations | Regularly check and adjust to optimize performance. |

| Lubrication System | Critical for reducing wear and ensuring smooth operation. | Longer Machine Life | Follow the recommended lubrication schedule strictly. |

| Material Feed Size | Optimal feed sizes lead to better crushing efficiency. | Enhanced Material Efficiency | Ensure the material size matches specifications to avoid blockage. |

| Monitoring Systems | Consider incorporating advanced monitoring for real-time performance data. | Improved Operational Insights | Use data analytics to predict maintenance needs and reduce downtime. |

Best Way To Choose Cone Crusher For Crushing Granite Your End-to-End Solution Market Leader

J

Jonathan White

Exceptional product quality! It’s clear that they stand behind their product with a strong after-sales service.

19 May 2025

S

Sophia Harris

Outstanding product quality combined with professional customer care. Highly recommend!

10 May 2025

G

Grace Gonzalez

Exceedingly satisfied with my purchase! Their customer support team is professional and very helpful.

09 May 2025

E

Elijah Sanchez

The product quality is outstanding! I was particularly impressed by the after-sales support.

24 May 2025

E

Eva Sanchez

The product is of great quality! The customer service team was very knowledgeable.

28 June 2025

D

David Allen

Outstanding product quality! I was greatly impressed with the after-sales service.

06 June 2025