High Manganese CH420 Bowl Liners for Wholesale Cone Crusher - Reliable Exporter

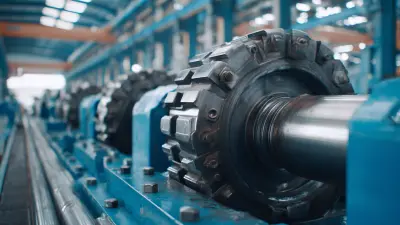

The CH420 bowl liners by Chengdu Zhixin Refractory Technology Co., Ltd. are engineered specifically for cone crushers, offering remarkable efficiency and durability. Made from high manganese steel, these liners are designed to withstand wear and impact, ensuring optimal performance in tough crushing environments. Their innovative design enhances crushing ratios and reduces downtime, making them a dependable choice for industries such as mining and construction. Tailored to fit CH420 models perfectly, these bowl liners minimize operational risks. With a strong focus on quality, each liner is subjected to thorough testing to meet rigorous industry standards, providing confidence for users. Invest in high manganese bowl liners from Chengdu Zhixin Refractory Technology Co., Ltd. to boost productivity and increase equipment longevity.Methods To Cone Crusher High Manganese Ch420 Bowl Liners Stands Out Where Service Meets Innovation

In the rapidly evolving landscape of the mining and construction industries, the demand for robust machinery components has never been higher. Chengdu Zhixin Refractory Technology Co., Ltd., established in 2010, stands out as a leader in the production of high manganese steel components, particularly the Ch420 bowl liners for cone crushers. Our commitment to innovation combined with unparalleled service sets us apart from competitors, making us the go-to partner for global procurement. At Chengdu Zhixin, we emphasize the importance of wear-resistant and high-temperature resistant materials in enhancing the longevity and performance of machinery. Our Ch420 bowl liners are meticulously crafted using advanced manufacturing processes and high-quality materials, ensuring they withstand the rigors of demanding environments. With a focus on both service and innovation, we provide tailored solutions to meet the specific needs of our clients, reinforcing our position as an industry frontrunner. Choosing Chengdu Zhixin means investing in reliability and efficiency. Our dedicated team of experts is always ready to support you with exceptional service, ensuring that your operation runs smoothly and effectively. Discover how our high manganese Ch420 bowl liners can enhance your machinery’s performance and drive your business forward, as we continue to set the standard where service meets innovation.

Methods To Cone Crusher High Manganese CH420 Bowl Liners Stands Out Where Service Meets Innovation

| Method | Description | Benefits | Innovation Aspect |

|---|---|---|---|

| Heat Treatment | Applying heat to enhance the hardness and durability of liners. | Increases lifespan and reduces replacement frequency. | Utilizes advanced thermal techniques for optimal strength. |

| Metal Composition Analysis | Testing and adjusting alloy mixtures to improve performance. | Enhances wear resistance and mechanical properties. | Incorporates data-driven approaches for material optimization. |

| Precision Engineering | Utilizing CNC technology to achieve precise dimensions. | Ensures exact fit, improving operational efficiency. | Advances in machining technology for high precision. |

| Surface Coating | Applying specialized coatings to reduce friction and wear. | Enhances performance and resistance to abrasion. | Innovative coating materials for increased longevity. |

| Regular Maintenance Protocols | Establishing preventative measures and regular checks. | Minimizes unexpected failures and downtimes. | Process innovations for predictive maintenance using IoT. |

why choose Cone Crusher High Manganese Ch420 Bowl Liners Pioneers in the Field Outperforms the Competition

J

Jessica Wilson

The product is fantastic! I appreciate how attentive the support staff was with my inquiries.

15 June 2025

L

Liam Scott

Impressive product quality! Customer service was prompt and addressed my concerns adeptly.

11 May 2025

O

Oliver Collins

I am very impressed! The quality is unmatched and the customer care team was very informative.

21 May 2025

Z

Zoe Patterson

Outstanding quality! Their dedicated support team made the after-sale experience effortless.

06 June 2025

S

Samuel Torres

Product quality is fantastic, and their after-sales support is incredibly commendable.

18 June 2025

N

Nathan Ryan

Outstanding quality product! The after-sales team’s support was excellent!

15 May 2025