Affordable Symons Cone Crusher Liners | Quality Options from Trusted Manufacturers

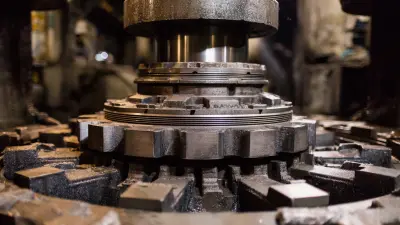

Cone Crusher Liners are crucial components engineered to enhance the performance and lifespan of Symons cone crushers. Chengdu Zhixin Refractory Technology Co., Ltd. specializes in producing high-quality liners that improve crushing efficiency and lower operational costs. Our liners are made from durable materials designed to endure demanding conditions while delivering optimal performance. With a commitment to precision and consistency, our products offer exceptional wear resistance, enabling your equipment to operate at peak efficiency over time. The innovative design of our Cone Crusher Liners ensures straightforward installation and compatibility with a range of Symons models. Choosing our liners contributes to increased productivity and minimized downtime, guaranteeing that your equipment performs its best. Trust Chengdu Zhixin Refractory Technology Co., Ltd. for dependable, high-performance solutions tailored to your crushing requirements. Experience enhanced operational capability with our outstanding Cone Crusher Liners.

How To Decide Between Cone Crusher Liners For Symons Your End-to-End Solution Sets the Industry Standard

Choosing the right cone crusher liners for your Symons equipment is crucial for optimizing performance and ensuring longevity. As a global supplier of high manganese steel products, Chengdu Zhixin Refractory Technology Co., Ltd. specializes in wear-resistant and high-temperature resistant materials, providing solutions that set the industry standard. Founded in 2010, our deep expertise in material science means we are committed to delivering durable crusher liners that reduce replacement frequency and improve crushing efficiency. When selecting liners, consider factors such as the material composition, wear patterns, and the specific operational requirements of your equipment. Our range of high manganese steel liners is engineered to withstand extreme conditions, providing superior resistance to abrasion and impact. By partnering with us, you'll gain access to not just standard products, but customized solutions tailored to your unique operational challenges. Investing in quality cone crusher liners is essential for maximizing your production capabilities while minimizing downtimes and costs. At Chengdu Zhixin, we understand these challenges and are equipped to assist global buyers in making informed decisions that enhance their equipment's performance. Explore our comprehensive offerings and experience the difference that high-quality wear-resistant materials can make in your operations today.

How To Decide Between Cone Crusher Liners For Symons Your End-to-End Solution Sets the Industry Standard

| Liner Type | Material | Average Lifespan (Hours) | Crushing Applications | Cost ($) |

|---|---|---|---|---|

| Standard Liner | High Manganese Steel | 1,500 | Primary Crushing | 1,200 |

| Medium Liner | Alloy Steel | 1,800 | Secondary Crushing | 1,500 |

| Fine Liner | High Chrome Iron | 2,000 | Tertiary Crushing | 1,800 |

| Heavy Duty Liner | Dense Alloy Steel | 2,500 | Quarrying | 2,200 |

Why Consider Cone Crusher Liners For Symons Trusted by Pros Manufacturers You Can Rely On

E

Emily Davis

I was truly impressed by the quality of the product. The customer service was remarkably efficient and supportive.

02 June 2025

K

Kimberly Lewis

What a great experience! The product quality is outstanding and the support team is very professional.

28 May 2025

E

Elijah Sanchez

The product quality is outstanding! I was particularly impressed by the after-sales support.

24 May 2025

H

Hannah Gray

I am very satisfied! The professionalism of the after-sales team was remarkable.

16 May 2025

O

Osman Ford

Incredible quality! I was impressed with the dedication of the after-sales support team.

02 June 2025

C

Chloe Sanchez

Unmatched quality and service! The post-purchase support exceeded my expectations.

13 June 2025