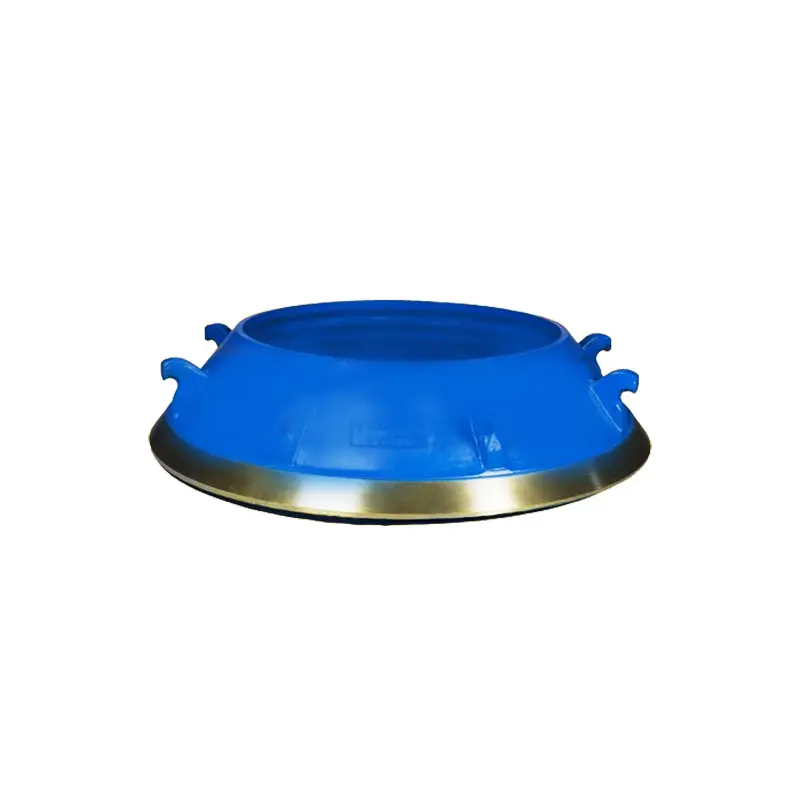

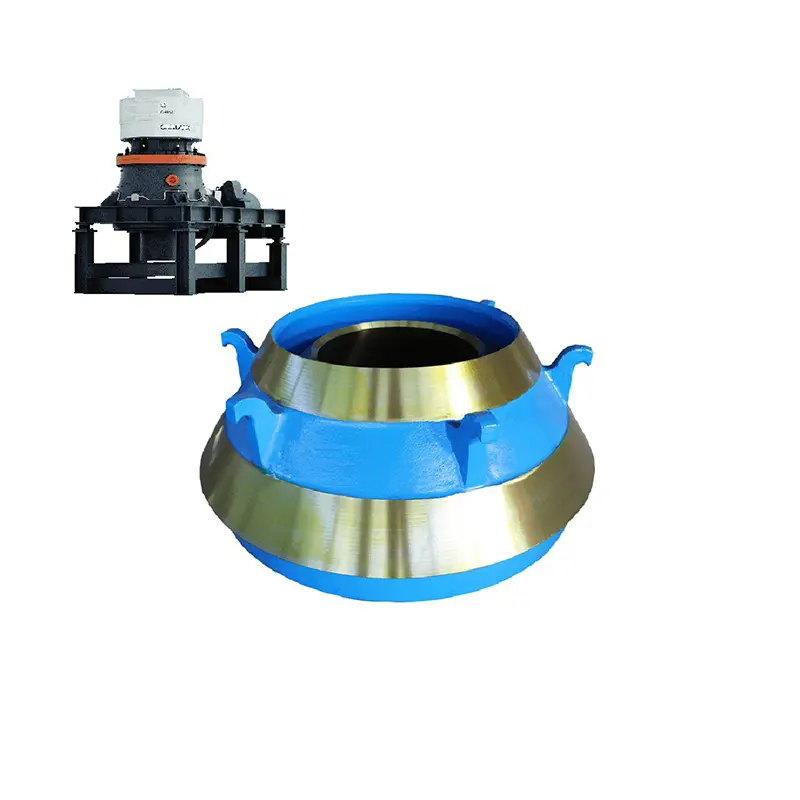

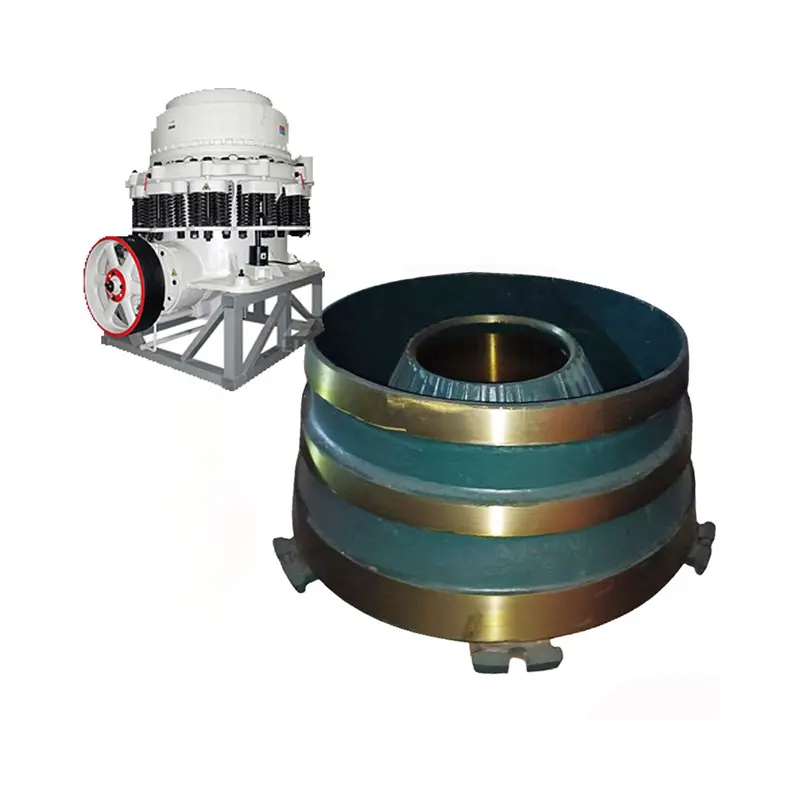

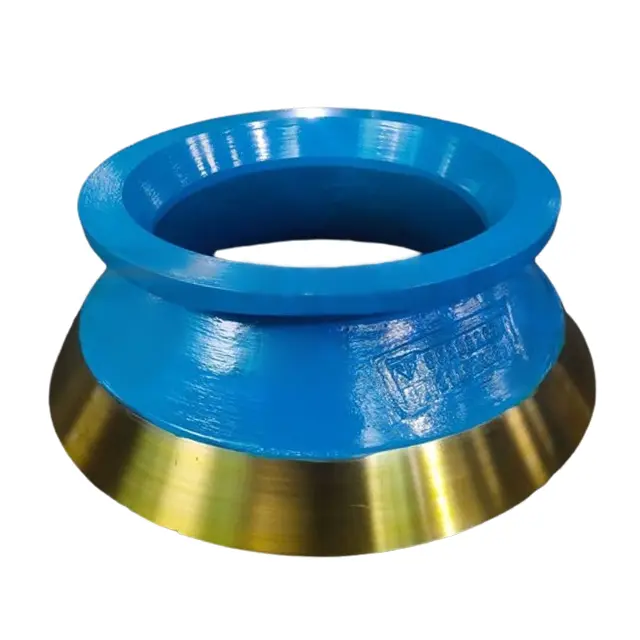

Cone crusher mantle and concave with longer service life

Product technology

We independently developed high-crystalline nanocompounds, which gradually and perfectly integrated a variety of rare metals with high-manganese steel substrates, and digitally and accurately controlled the entire casting process, making our product quality far superior to similar products. HRC>68°, matrix impact toughness>119J/cm2, and tensile strength greater than 1500MPa.

After actual use by many customers, our high-performance crusher wear parts have a service life of 2-3 times that of conventional wear parts. Choosing our crusher plates can effectively help you reduce the frequency of downtime to replace parts, save maintenance costs, and increase production capacity.

In an actual case, a large glass production company used a jaw crusher jaw plate that could crush about 170,000 tons of quartz stone, but after using the jaw crusher jaw plate we provided, it could produce more than 600,000 tons, and the service life was increased from 20 days to two months.

Product display

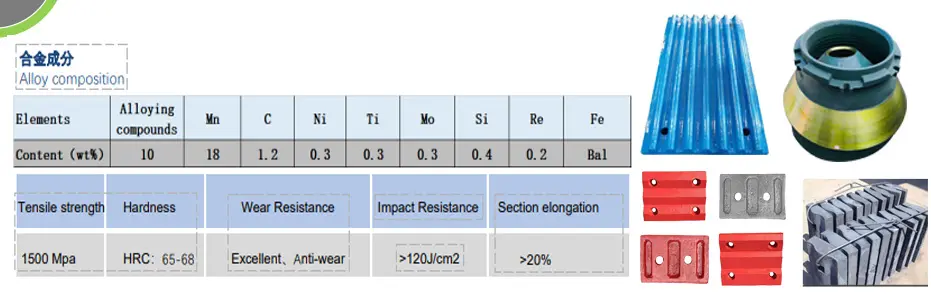

Product material

Manganese(Mn): The main alloying element in high manganese steel, with a content generally above 11%. Manganese can improve the wear resistance, toughness and hardness of high manganese steel, while reducing low-temperature brittleness and hot work hardening tendency.

Carbon (C): The content is usually between 0.9%-1.3%. Carbon can improve the hardness and strength of high manganese steel, but will reduce its toughness and impact resistance.

Silicon (Si): The content is generally between 0.2%-0.5%. Silicon can improve the toughness and impact resistance of high manganese steel, while reducing its brittleness and porosity.

Chromium (Cr): The content is usually between 0.5%-2.0%. Chromium can improve the hardness and wear resistance of high manganese steel, while enhancing its oxidation resistance and corrosion resistance.

Molybdenum (Mo): The content is generally not more than 0.3%. Molybdenum can improve the strength and wear resistance of high manganese steel, while enhancing its corrosion resistance.

Cobalt (Co): The content is usually no more than 1%. Cobalt can improve the wear resistance and toughness of high manganese steel, while reducing its hardness and brittleness.

The casting process of the product is:

Drawing confirmation→ Mold design and making→Molding→ Melting→ Pouring→ Cooling and shakeout → Cleaning → Heat treatment → Grinding → Inspection and painting.

Each product will pass strict quality inspection before leaving the factory to ensure product quality.

What you should offer?

A. Please offer the drawing file if you had.

B. If you had no drawing file. In order to help us to find the drawing file accordingly, please offer the photo of crusher with its label, the part number of wear parts.