Cone crusher mantle and concave wear-resistant spare parts supply factory

Installation and commissioning

Pre-installation inspection: Check the dimensional accuracy and surface quality of the crusher liner to ensure that there are no defects such as cracks, wear, and deformation, and prepare the tools and materials required for installation.

Correct installation: According to the requirements of the equipment manual, the concave and mantle is correctly installed on the equipment, and fastened with special bolts or other fixing devices to ensure a firm installation.

Commissioning and operation: After the installation is completed, perform no-load commissioning to check the operation of the crusher liner, including whether there is abnormal vibration or noise.

Crushing operation

● Control the feed particle size: Strictly control the feed particle size, not exceeding the maximum particle size allowed by the design of the cone crusher, to prevent excessively large particles from entering the crushing chamber and causing blockage or damage to the crusher liner.

● Monitor the operating parameters: During the operation of crushing, closely monitor parameters such as current, voltage, oil temperature, oil pressure, and the working status of the crusher wear parts.

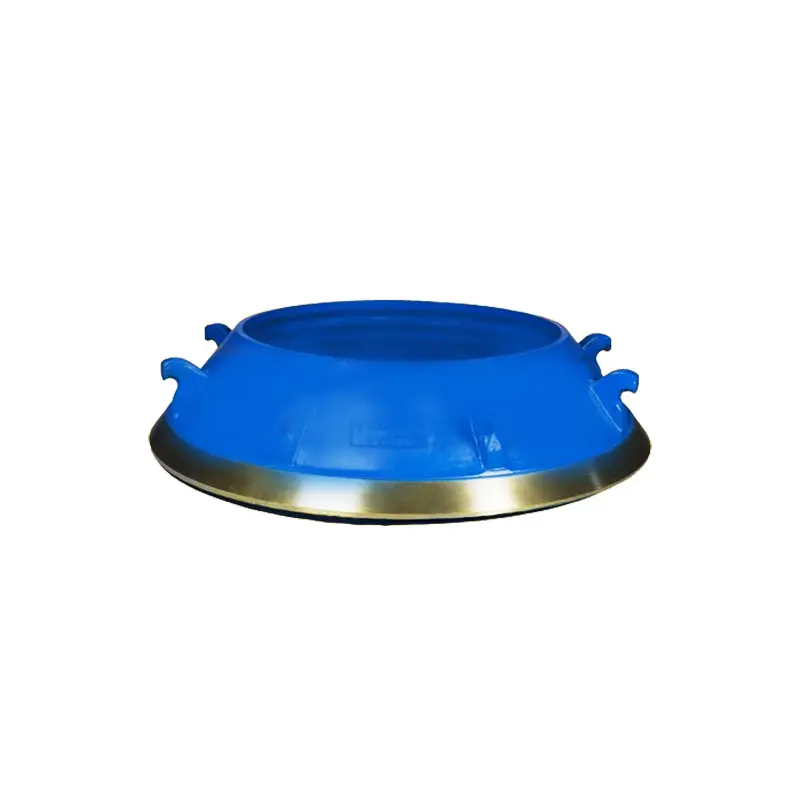

Product display

Maintenance

● Regular inspection: Regularly stop the machine to check the wear of the crusher lining, including the degree of wear and whether there are cracks, so as to find problems in time and take measures accordingly.

● Timely replacement: When the crusher wear parts are worn to a certain extent, affecting the crushing effect and production efficiency, a new wear part should be replaced in time.

● Cleaning and lubrication: Keep the surface of the crusher liner clean to prevent dust and impurities from accumulating and affecting heat dissipation and crushing effects. At the same time, lubricate each lubrication point of the crusher according to the prescribed cycle and requirements.

Safety precautions

● Avoid iron: The crushing plant needs to be equipped with electromagnetic or other metal detection to prevent iron or other metals from falling into the crushing chamber and damaging the wear parts of the crusher. Even our high-performance crusher concave and mantle cannot withstand the repeated impact of metal blocks.

● Avoid wet crushing: wet crushing here means that the moisture content of the crushed material is much greater than the normal humidity. For example, in order to reduce dust, some crushing plants flush water into the crushing chamber during the crushing process, which will affect the performance or even damage the wear-resistant parts of the crusher.