OEM Cone Crusher Mantle and Bowl Liner Wear Parts Supplier & Manufacturer

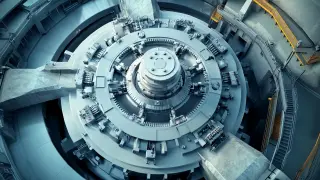

Engineered for exceptional durability and high performance, the Cone Crusher Mantle and Bowl Liner from Chengdu Zhixin Refractory Technology Co., Ltd. are vital wear components for efficient mining operations. Made from high-grade materials, these parts are designed to endure the intense forces and abrasive environments typical in crushing processes. The Cone Crusher Mantle ensures effective material pulverization, while the Bowl Liner provides optimal protection and stability, minimizing the frequency of replacements. Our precisely designed components guarantee compatibility with a range of cone crusher brands, boosting productivity and reducing operational costs. With a strong commitment to quality and innovation, Chengdu Zhixin Refractory Technology Co., Ltd. offers superior wear parts that extend equipment lifespan. Investing in our Cone Crusher Mantle and Bowl Liner translates to enhanced reliability and efficiency, giving a competitive advantage in the mining industry. Upgrade your machinery with our premium wear parts and experience unmatched performance enhancements.Must-Know Tips For Cone Crusher Mantle Bowl Liner Wear Parts Mining Machine Parts Supplies the World’s Top Brands Exceeds Industry Benchmarks

In the ever-evolving world of mining machinery, one of the critical components that ensures operational efficiency is the wear parts of cone crushers. At Chengdu Zhixin Refractory Technology Co., Ltd., established in 2010, we specialize in producing high-quality, wear-resistant materials and high manganese steel components designed to withstand the rigors of mining operations. Our commitment to excellence means we not only meet but often exceed industry benchmarks in the manufacture of cone crusher mantle and Bowl Liners. Understanding the specifics of wear parts is essential for buyers looking to optimize their equipment's performance. The cone crusher mantle and bowl liner play a pivotal role in the crushing process, and the right materials significantly enhance longevity and efficiency. Our advanced research and production capacity enable us to supply wear parts that reduce downtime and maintenance costs, making them a wise choice for global procurement managers. When sourcing wear parts for mining equipment, it is crucial to consider reliability, performance, and industry standards. Our wear-resistant products are specifically engineered to provide superior durability, ensuring your operations run smoothly. Partnering with Chengdu Zhixin means you are investing in cutting-edge technology, rigorous quality control, and unparalleled service, all aimed at maximizing your operational success. Discover how our innovative solutions can elevate your mining operations and contribute to your bottom line today.

Must-Know Tips For Cone Crusher Mantle Bowl Liner Wear Parts Mining Machine Parts Supplies the World’s Top Brands Exceeds Industry Benchmarks

| Part Name | Material | Hardness (HRC) | Weight (kg) | Application |

|---|---|---|---|---|

| Mantle | High Carbon Steel | 50-60 | 120 | Rock Crushing |

| Bowl Liner | Manganese Steel | 45-55 | 150 | Aggregate Processing |

| Concave | Alloy Steel | 52-60 | 100 | Mining Operations |

| Spider Cap | Cast Steel | 40-50 | 70 | Primary Crushing |

| Dust Seal | Rubber | N/A | 5 | Sealing |

Best Brands For Cone Crusher Mantle Bowl Liner Wear Parts Mining Machine Parts in 2025 Industry Leaders

R

Ryan Lee

Excellent experience overall! The after-sales staff provided valuable insights that enhanced my usage of the product.

01 July 2025

M

Millie Hughes

Fantastic product! The professionalism shown by the support staff was greatly appreciated.

25 June 2025

H

Hailey Collins

Highly recommend! The professionalism of the support staff was impressive.

01 June 2025

O

Oliver Young

The quality is exceptional! The customer service team is knowledgeable and professional.

19 June 2025

B

Brody Allen

The craftsmanship is top-tier. The support team after the purchase was incredibly helpful.

24 June 2025

C

Cameron Hill

Impressive product! Their commitment to customer service during the follow-up was remarkable.

20 May 2025