Premium Cone Crusher Eccentric Bushing | Leading Manufacturers & Suppliers

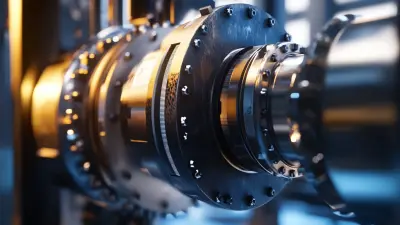

The Cone Crusher Parts Eccentric Bushing is a vital component engineered for optimal performance in crushing applications. Manufactured by Chengdu Zhixin Refractory Technology Co., Ltd., this bushing ensures accurate alignment and smooth movement of the cone crusher's mantle, enhancing operational efficiency. Built from high-quality materials, it is designed to endure the demands of heavy-duty mining and aggregate processing environments. Choosing Chengdu Zhixin signifies a commitment to reliability and quality, helping to maximize your operation's productivity. Experience the excellence of our Cone Crusher Parts Eccentric Bushing for superior performance in your crushing processes.Expert Tips For Cone Crusher Parts Eccentric Bushing Products Manufacturer

When it comes to sourcing high-quality cone crusher parts, particularly the eccentric bushing, partnering with a reputable manufacturer is crucial. Chengdu Zhixin Refractory Technology Co., Ltd., established in 2010, has built a strong reputation in the industry for specializing in wear-resistant, high-temperature resistant materials, and high manganese steel machinery components. Our extensive experience in production and research has equipped us with the expertise to deliver top-notch eccentric bushings that enhance the performance and longevity of your crushing equipment. One of the key factors to consider when selecting eccentric bushings is the material quality. The high manganese steel we utilize is renowned for its excellent impact and abrasion resistance, making it an ideal choice for strenuous mining and quarrying applications. Furthermore, our strict quality control processes ensure that every product meets international standards, providing you with the reliability you need for efficient operations. By choosing Chengdu Zhixin, you not only invest in superior products but also in a partnership that values innovation and customer service. In addition, our customer-centric approach means we’re here to tailor solutions to your specific needs, offering various sizes and specifications to fit different models of cone crushers. Whether you are looking for bulk orders or customized solutions, our team is ready to assist. Trust Chengdu Zhixin Refractory Technology Co., Ltd. for all your eccentric bushing needs, and experience the difference that quality and expertise can make in your operations.

Expert Tips For Cone Crusher Parts Eccentric Bushing Products Manufacturer

| Tip Number | Expert Tip | Importance Level | Common Issues | Recommended Solution |

|---|---|---|---|---|

| 1 | Regularly inspect for wear and tear. | High | Increased vibration & noise. | Conduct routine maintenance checks. |

| 2 | Use only high-quality replacement parts. | Critical | Frequent breakdowns of the machine. | Source parts from reputable suppliers. |

| 3 | Ensure proper lubrication. | High | Overheating and damage to bushings. | Follow manufacturer guidelines for lubrication schedule. |

| 4 | Monitor operational load. | Medium | Excessive wear on bushings. | Adjust load as per machine specifications. |

| 5 | Use proper installation techniques. | Critical | Misalignment and operational issues. | Follow best practices for installation. |

Top 5 Cone Crusher Parts Eccentric Bushing Manufacturers You Can Rely On Outperforms the Competition

W

William Miller

It’s rare to find such a quality product accompanied by fantastic customer support. Truly a great investment.

20 May 2025

K

Kimberly Lewis

What a great experience! The product quality is outstanding and the support team is very professional.

28 May 2025

O

Oliver Collins

I am very impressed! The quality is unmatched and the customer care team was very informative.

21 May 2025

M

Millie Hughes

Fantastic product! The professionalism shown by the support staff was greatly appreciated.

25 June 2025

M

Mia Clark

I was impressed with the quality! The after-sales service was professional and helpful.

29 May 2025

H

Hailey Collins

Highly recommend! The professionalism of the support staff was impressive.

01 June 2025