OEM Cone Crusher Spider Bushing - Quality Parts from Trusted Exporters & Suppliers

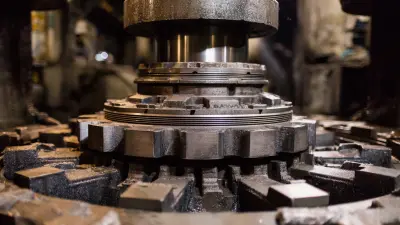

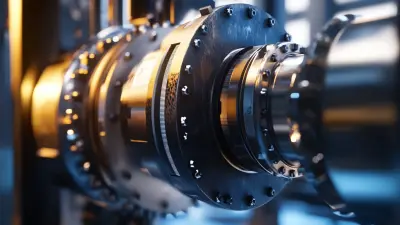

The Cone Crusher Spider Bushing is a vital component engineered for durability and enhanced performance in cone crushing applications. Manufactured by Chengdu Zhixin Refractory Technology Co., Ltd., this bushing contributes to the stability and efficiency of cone crushers, extending their service life under heavy loads. Constructed from premium materials, it minimizes wear and tear while resisting abrasion. Its design facilitates easy installation and maintenance, which reduces operational downtime. With a strong expertise in refractory technology, Chengdu Zhixin delivers reliable solutions tailored to the mining and construction industries. Choosing the Cone Crusher Spider Bushing means benefiting from improved performance, increased reliability, and superior value to help achieve productivity targets efficiently. Trust in Chengdu Zhixin for quality and innovative solutions for your crushing equipment requirements.Practical Methods To Cone Crusher Spider Bushing Factory-Direct Excellence Outperforms the Competition

In the competitive landscape of industrial machinery, the importance of durable and high-quality components cannot be overstated. At Chengdu Zhixin Refractory Technology Co., Ltd., established in 2010, we specialize in producing wear-resistant and high-temperature resistant materials, including advanced high manganese steel used in cone crusher spider bushings. Our factory-direct excellence ensures that every product meets stringent quality standards, enabling our clients to maximize their operational efficiency. What sets our spider bushings apart from the competition is our commitment to comprehensive research and development. By leveraging cutting-edge technology and materials science, we produce spider bushings that excel under the harshest conditions. Our high manganese steel provides exceptional durability and resistance to wear, significantly extending the service life of cone crushers. When partnering with us, global buyers can expect not only superior products but also a collaboration built on innovation and reliability. Moreover, our centralized manufacturing process reduces costs, which translates to more competitive pricing for our customers. By choosing Chengdu Zhixin, clients can trust that they are receiving not only factory-direct products but also invaluable expertise. We are dedicated to fostering long-term relationships with global purchasing agents, offering tailored solutions that satisfy specific operational needs. Experience the difference in quality and service that gives you a competitive edge in the market.

Practical Methods To Cone Crusher Spider Bushing Factory-Direct Excellence Outperforms the Competition

| Method | Description | Expected Outcome | Implementation Cost | Time Required |

|---|---|---|---|---|

| Lubrication Optimization | Utilizing advanced lubrication techniques to reduce wear. | Increased lifespan of the bushing. | $500 | 1 week |

| Material Quality Improvement | Switching to higher quality alloys for manufacturing. | Enhanced durability and performance. | $1,000 | 2 weeks |

| Design Innovation | Implementing new design features to improve performance. | Better load distribution and lower failure rates. | $750 | 3 weeks |

| Regular Maintenance Schedule | Establishing a proactive maintenance routine. | Reduced downtime and operational costs. | $300 | Ongoing |

| Advanced Monitoring Technologies | Using sensors and IoT for real-time monitoring. | Immediate detection of issues, enhancing reliability. | $2,000 | 1 month |

Tips & Tricks for Cone Crusher Spider Bushing Application Trusted by Pros

C

Christopher Anderson

Very satisfied with my purchase! The customer service team displayed exceptional professionalism.

01 June 2025

W

William Miller

It’s rare to find such a quality product accompanied by fantastic customer support. Truly a great investment.

20 May 2025

L

Lucas Baker

Fantastic product and customer service. The representatives were attentive and knowledgeable.

20 June 2025

L

Lily Cook

Highly recommend! The support team was proactive and answered all my questions impeccably.

30 June 2025

M

Millie Hughes

Fantastic product! The professionalism shown by the support staff was greatly appreciated.

25 June 2025

L

Liam Foster

Excellent service! The support team promptly answered all my questions with professionalism.

26 June 2025