Premium Cone Crusher Wear Parts from Trusted Suppliers & Factories for Superior Durability

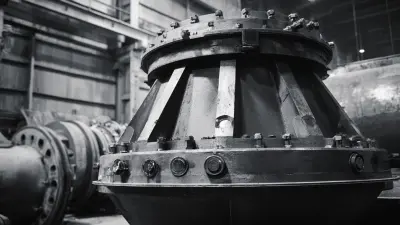

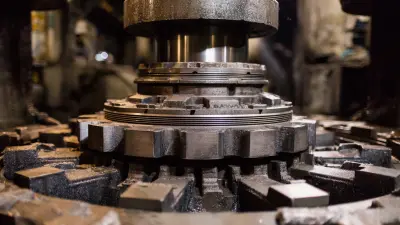

Chengdu Zhixin Refractory Technology Co., Ltd. specializes in producing high-quality wear components for cone crushers, aimed at enhancing both durability and performance in crushing applications. Our products are engineered with advanced materials to provide superior resistance to wear, abrasion, and high-impact conditions, which results in extended service life and lower maintenance expenses. With extensive expertise in the mining and construction sectors, we offer a wide range of compatible wear parts for various brands and models of cone crushers. Our dedication to quality and innovation ensures that each component adheres to strict industry standards. By choosing our Cone Crusher Wear Parts, you invest in reliability and efficiency. Whether you need bowls, mantles, or liners, our parts are specifically designed for optimal fit and function, ensuring maximum productivity and minimal downtime in your operations.Discovering Cone Crusher Wear Part Dominates Pioneers in the Field

In the ever-evolving landscape of the mining and aggregate industries, ensuring the reliability and efficiency of machinery is paramount. Chengdu Zhixin Refractory Technology Co., Ltd., established in 2010, stands at the forefront of this demand by specializing in the research and production of wear-resistant materials. Our commitment to excellence positions us as a pioneer in providing high-quality cone crusher wear parts, essential for maximizing the performance and longevity of crushing equipment. The wear parts designed and manufactured by Zhixin are crafted from high manganese steel and tailored to withstand the most challenging conditions, ensuring that your operations run smoothly. Our innovative solutions not only enhance productivity but also reduce downtime and maintenance costs, allowing global purchasers to optimize their investments. As we continue to lead in the field of high-temperature resistant materials, we invite you to discover how our cutting-edge technology and unwavering dedication can elevate your business outcomes. Choosing Zhixin means partnering with a company that values quality and customer satisfaction above all. We understand the critical nature of your supply chain, and our team is committed to delivering durable, reliable wear parts that meet your exact specifications. Let's work together to stay ahead in this competitive industry and drive your success with our advanced wear solutions.

Discovering Cone Crusher Wear Part Dominates Pioneers in the Field

| Manufacturer | Material Type | Wear Part Type | Typical Service Life (Hours) | Application |

|---|---|---|---|---|

| Company A | Manganese Steel | Mantle | 500 | Primary Crushing |

| Company B | High Carbon Steel | Concave | 600 | Secondary Crushing |

| Company C | Alloy Steel | Bowl Liner | 700 | Tertiary Crushing |

| Company D | Chrome Steel | Spider Cap | 450 | Miscellaneous Applications |

| Company E | Martensitic Steel | Shoes | 800 | Recycling |

How To Source Cone Crusher Wear Part Market Leader Guarantees Peak Performance

J

Jonathan White

Exceptional product quality! It’s clear that they stand behind their product with a strong after-sales service.

19 May 2025

D

David Johnson

Great product and even better service! The representatives are knowledgeable and professional.

13 May 2025

B

Brandon Lee

Exceptional service! After my purchase, the support team guided me perfectly through the setup.

14 May 2025

Z

Zoe Patterson

Outstanding quality! Their dedicated support team made the after-sale experience effortless.

06 June 2025

M

Millie Hughes

Fantastic product! The professionalism shown by the support staff was greatly appreciated.

25 June 2025

M

Marcus Brooks

Fantastic product! The customer support team was friendly and extremely helpful.

31 May 2025