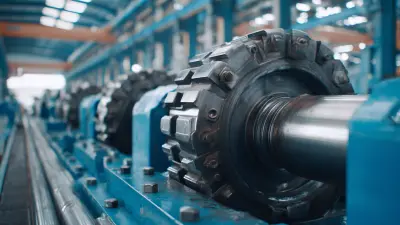

High-Quality ODM Cone Crusher Wear Parts from Leading Factories & Exporters

Cone Crusher Wear Resistant Parts are crucial for maximizing the lifespan and efficiency of crushing operations. Chengdu Zhixin Refractory Technology Co., Ltd. manufactures high-quality wear-resistant components designed to endure extreme conditions and prolong the service life of cone crushers. Made from premium materials, our products offer exceptional resistance to impact, abrasion, and general wear, leading to reduced downtime and lower maintenance costs. Our commitment to innovation ensures that these components meet stringent industry standards while providing reliable performance. Compatible with a variety of cone crusher models, they enhance crushing capacity and maintain optimal function in challenging environments. Choosing our wear-resistant parts means improving productivity and achieving significant returns on investment. Trust Chengdu Zhixin Refractory Technology Co., Ltd. for expertly crafted solutions tailored to your operational needs.Where the Value Lies Cone Crusher Wear Resistant Parts Products Custom Solutions,

In the competitive landscape of mining and mineral processing, the durability and reliability of equipment play a crucial role in operational efficiency. Chengdu Zhixin Refractory Technology Co., Ltd., established in 2010, specializes in manufacturing wear-resistant and high-temperature resistant materials, along with high manganese steel components tailored for industrial machinery. Our commitment to research and innovation ensures that we deliver products that precisely meet the rigorous demands of the market. One standout offering is our custom solutions for cone crusher wear-resistant parts. We understand that different applications require unique specifications, which is why we provide tailored solutions that enhance performance and longevity. Our advanced materials are engineered to withstand extreme conditions, reducing downtime and maintenance costs for our clients. By choosing our products, global buyers can benefit from increased operational efficiency and a significant return on investment. At Chengdu Zhixin, we pride ourselves on our expert knowledge and the capacity to support our partners worldwide. Our dedicated team is poised to collaborate with clients to develop solutions that not only meet but exceed their expectations. Trust us to be your reliable partner in optimizing equipment lifespan and performance in the challenging environments of the mining and industrial sectors.

Where the Value Lies in Cone Crusher Wear Resistant Parts Products Custom Solutions

| Part Name | Material | Application | Durability (Hours) | Customization Options |

|---|---|---|---|---|

| Mantle | High Manganese Steel | Secondary Crushing | 800 - 1200 | OEM / Customized Designs |

| Concave | Alloy Steel | Tertiary Crushing | 700 - 1100 | Customized Profiles |

| Bowl Liner | High Chrome Iron | Aggregate Production | 1000 - 1500 | Special Coatings Available |

| Jaw Plate | Mixed Manganese | Primary Crushing | 600 - 900 | Various Jaw Formats |

| Feed Plate | High Strength Steel | Feed Distribution | 500 - 700 | Customized Sizing |

Not to Be Missed Cone Crusher Wear Resistant Parts From Concept to Delivery Custom Solutions,

B

Brandon Lee

Exceptional service! After my purchase, the support team guided me perfectly through the setup.

14 May 2025

N

Noah Hall

The craftsmanship is top-tier. Post-purchase support was professional and very helpful.

12 June 2025

S

Samuel Torres

Product quality is fantastic, and their after-sales support is incredibly commendable.

18 June 2025

L

Lily Cook

Highly recommend! The support team was proactive and answered all my questions impeccably.

30 June 2025

M

Mikayla Phillips

I had an excellent purchasing experience! Their customer support was both professional and friendly.

22 May 2025

E

Emma Ramirez

The craftsmanship is excellent! I appreciated the professionalism of the support team.

12 May 2025