High-Quality Cone Crusher Lock Cylinder - Premium Wearing Parts Manufacturer

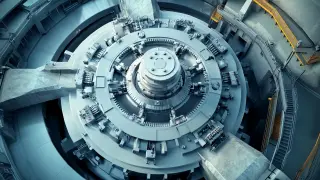

The Lock Cylinder for Cone Crushers, produced by Chengdu Zhixin Refractory Technology Co., Ltd., is a critical component designed to improve the efficiency and longevity of cone crushing machines. Crafted from high-quality materials, this lock cylinder provides secure and dependable locking mechanisms during crushing operations, significantly lowering the likelihood of mechanical failures. Its sturdy design is built to withstand extreme pressures and tough environmental conditions, making it suitable for a range of industrial applications. Prioritizing precision and performance, the lock cylinder enhances the functionality of the crusher, leading to greater productivity and reduced maintenance costs. Chengdu Zhixin Refractory Technology Co., Ltd. is committed to delivering top-notch products that satisfy the demanding needs of the mining and construction industries. Choosing this lock cylinder ensures enhanced reliability and durability for your cone crushers, contributing to superior operational results. Invest in reliable performance with our high-quality lock cylinders.Reasons to Choose Cone Crusher Wearing Parts Lock Cylinder Trusted by Pros Ahead of the Curve

When it comes to maintaining the efficiency and longevity of cone crushers, the quality of wearing parts is paramount. At Chengdu Zhixin Refractory Technology Co., Ltd., we specialize in producing high-performance wear-resistant materials, particularly high manganese steel components that stand up to the rigors of industrial applications. Established in 2010, our expertise positions us at the forefront of innovation, making us a trusted partner for clients worldwide seeking reliable solutions. One standout feature of our offerings is the lock cylinder for cone crusher wearing parts. Designed with precision and built to last, our lock cylinders ensure optimal performance by securely holding wearing parts in place, reducing the risk of wear and tear. This not only enhances the overall efficiency of the machinery but also minimizes downtime due to parts changeovers, allowing your operations to stay ahead of the competition. By choosing our lock cylinder, you are investing in a product that industry professionals reliably attribute their success to. With a commitment to cutting-edge research and development, we continuously refine our materials and processes to meet the evolving needs of the market. When you select Chengdu Zhixin Refractory Technology Co., Ltd. for your cone crusher wearing parts, you align with a leader in high-temperature resistant and wear-resistant technology. Empower your equipment with components designed for durability, reliability, and unmatched performance, ensuring you stay ahead of the curve in today's demanding industrial landscape.

Reasons to Choose Cone Crusher Wearing Parts Lock Cylinder Trusted by Pros Ahead of the Curve

| Feature | Description | Benefits |

|---|---|---|

| Material Quality | High-grade alloy steel | Enhanced durability and resistance to wear |

| Precision Engineering | Manufactured with tight tolerances | Improved performance and reduced downtime |

| Easy Installation | User-friendly design | Faster assembly and less maintenance time |

| Consistent Quality Control | Rigorous testing protocols | Reliable performance across all applications |

| Versatility | Compatible with various crusher models | Flexibility in application and reduced inventory needs |

Best Brands For Cone Crusher Wearing Parts Lock Cylinder Market Leader Is The Best

I

Isabella King

The level of support I received after my purchase was outstanding! I highly recommend this product.

04 June 2025

E

Ella Adams

I had a wonderful experience! The product quality is fabulous, and the after-sales team is super helpful.

30 June 2025

Z

Zoe Patterson

Outstanding quality! Their dedicated support team made the after-sale experience effortless.

06 June 2025

S

Samuel Torres

Product quality is fantastic, and their after-sales support is incredibly commendable.

18 June 2025

N

Natalie Brown

I had an excellent purchasing experience! Their team was professional and very helpful.

05 July 2025

N

Nathan Ryan

Outstanding quality product! The after-sales team’s support was excellent!

15 May 2025