Affordable Crusher Cone Displacement Sensors - Quality Exporter & Supplier

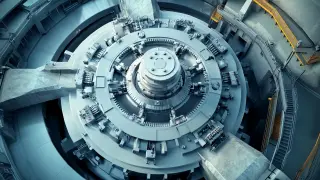

The Crusher Cone Displacement Sensor is a state-of-the-art device designed to boost the efficiency and reliability of crushing operations. By precisely measuring the displacement of the crusher's cone, this sensor delivers real-time data that facilitates accurate adjustments, ensuring optimal performance while reducing equipment wear and tear. Manufactured by Chengdu Zhixin Refractory Technology Co., Ltd., a recognized leader in advanced refractory solutions, this sensor is engineered to endure the challenging conditions found in the mining and aggregate industries. Its durable design promotes longevity and dependable function, thereby minimizing downtime and maintenance expenses. With straightforward integration into existing systems, this displacement sensor is vital for facilities aiming to enhance their crushing processes, improve safety, and elevate overall productivity.Expert Tips For Crusher Cone Crusher Displacement Sensor From Concept to Delivery Market Leader

In the ever-evolving world of industrial machinery, the importance of precision and reliability cannot be overstated. Chengdu Zhixin Refractory Technology Co., Ltd., established in 2010, has emerged as a leader in the field of high-temperature resistant materials and high manganese steel equipment, especially in the domain of crusher cone crusher displacement sensors. These sensors play a critical role in optimizing the performance of crushing machines by providing real-time feedback on the positioning of the crushing cone, ensuring operational efficiency and reducing downtime. To help global buyers understand the intricacies of crusher cone crusher displacement sensors, we present expert tips from concept to delivery. First and foremost, it's essential to consider the specific operational demands of your machinery. Selecting sensors that can withstand extreme temperatures and harsh environments is crucial for maintaining consistent performance. Our advanced wear-resistant materials and high manganese steel components are designed to meet these demanding conditions, providing you with long-lasting and reliable solutions. Additionally, collaboration throughout the supply chain is key to successful implementation. At Chengdu Zhixin, we pride ourselves on our commitment to quality and innovation, ensuring that our products not only meet but exceed international standards. By choosing us as your partner, you gain access to cutting-edge technology and expert knowledge that can enhance your operational capabilities from development through to delivery. Investing in high-quality displacement sensors will not only improve the efficiency of your crushing processes but also contribute to significant savings in maintenance and operational costs.

Expert Tips For Crusher Cone Crusher Displacement Sensor From Concept to Delivery Market Leader

| Tip # | Expert Tip | Importance | Implementation |

|---|---|---|---|

| 1 | Ensure proper calibration of the displacement sensor. | High | Regularly check against known standards. |

| 2 | Implement routine maintenance schedules. | Medium | Create a checklist for inspections. |

| 3 | Use high-quality materials to avoid wear. | High | Source from reputable suppliers. |

| 4 | Train staff on the importance of sensor accuracy. | Medium | Conduct workshops and training sessions. |

| 5 | Monitor performance data regularly. | High | Utilize data analytics tools to track trends. |

10 Essential Tips For Crusher Cone Crusher Displacement Sensor Supplies the World’s Top Brands Stands Out

E

Emily Davis

I was truly impressed by the quality of the product. The customer service was remarkably efficient and supportive.

02 June 2025

J

Jessica Wilson

The product is fantastic! I appreciate how attentive the support staff was with my inquiries.

15 June 2025

M

Megan Thomas

Top-quality product with a responsive support team. They made the whole experience seamless!

05 June 2025

A

Abigail Stewart

Excellent purchase experience! Their post-sale support was patient and remarkably helpful.

11 May 2025

J

James Torres

Exceptional product quality and a very professional customer service team to back it up!

29 June 2025

C

Chloe Morgan

The quality truly impressed me! The support staff was professional and very helpful.

28 June 2025