Casting Factory Ore Crushing Jaw Plate

Brief introduction to the jaw plates

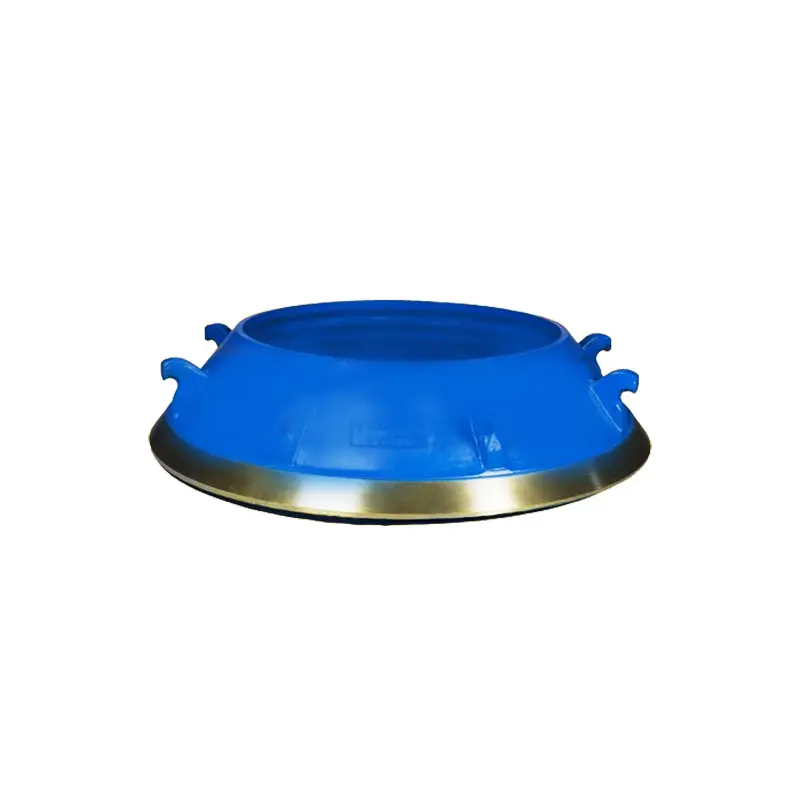

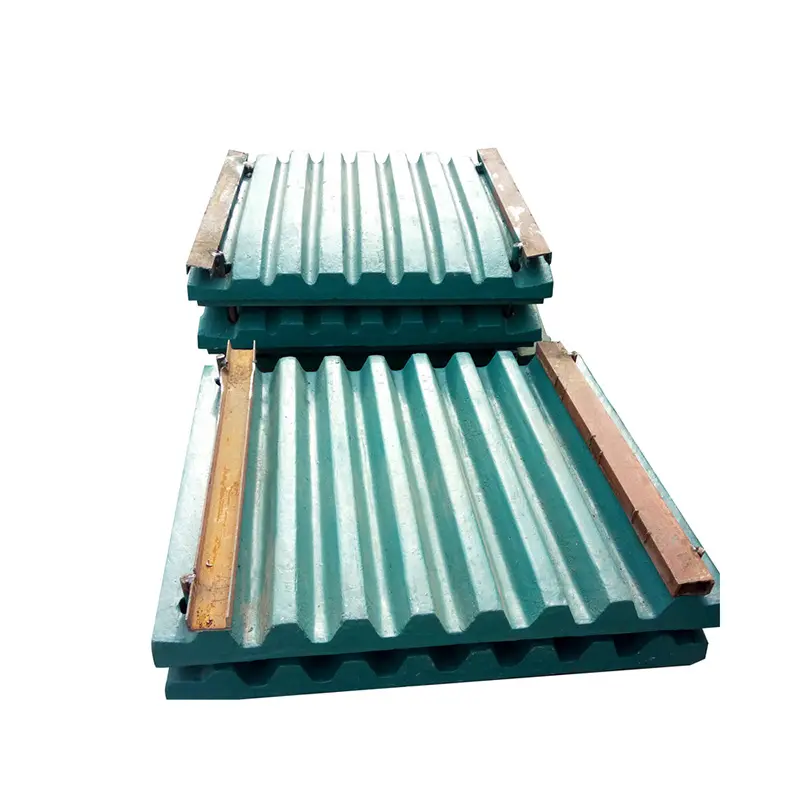

The jaw crusher jaw plate is named as tooth plate too, which is the main working part of the jaw crusher, which is divided into a movable jaw and a fixed jaw. The movable jaw plate and the fixed jaw plate form a crushing chamber to crush materials. When designing, the crushing tooth plates of the movable jaw and the fixed jaw should have tooth peaks facing tooth valleys. In this way, in addition to the extrusion effect on the material during crushing, there is also a bending effect, and the material is easier to crush. When selecting materials, in order to increase the service life of the tooth plate, the material is manganese steel containing more than 12% manganese, and ZGMn13 is commonly used.

During operation, the movable jaw is attached to the movable tooth plate to perform a compound pendulum motion, forming an angle with the fixed tooth plate to squeeze the stone. Therefore, the jaw crusher tooth plate is more prone to wear and needs to be replaced within a certain period of time. In order to extend its service life, its shape is generally designed to be symmetrical between the upper and lower ends, that is, when one end is worn, it can be turned around for use. The movable tooth plate and the fixed tooth plate are the main beneficiations when crushing stones. The movable tooth plate is installed on the movable jaw to protect the movable jaw.

Product display