Factory Direct Sale New Mining Machinery Crusher Jaw Plate

Product introduction

The wear parts of jaw crusher include movable jaw plate, fixed jaw plate, side guard plate, toggle plate, bearing, spring pull rod and spring components. We mainly supply high-performance jaw plates with 2-3x longer service life.

Fixed jaw and movable jaw: The jaw plate is the main working part of the jaw crusher and bears huge impact loads. During the crushing process, the edge of the fixed and movable jaw plate will be severely worn, and the wear is mostly concentrated in the middle and lower parts. This is due to the repeated impact and friction of the material during the crushing process. The shape of the fixed and movable jaw plate is designed to be symmetrical up and down, so when one end of the fixed and movable jaw plate is worn, it can be turned around and used. In order to extend its service life, the fixed and movable jaw plates are generally made of materials with good hardness and wear resistance such as high manganese steel, such as ZGMn13 material. The replacement cycle of the fixed and movable jaw plates is generally from several months to about half a year, depending on factors such as the use conditions, stone hardness and equipment load.

Side guards: The side guards are located on the left and right inner sides of the jaw crusher frame to protect the body of the jaw crusher. Under the impact of materials, the side guards will wear. When the wear of the side guards reaches a certain extent, new side guards need to be replaced. The replacement cycle of the side guards is generally longer, usually about half a year, depending on the use conditions and the working intensity of the crusher.

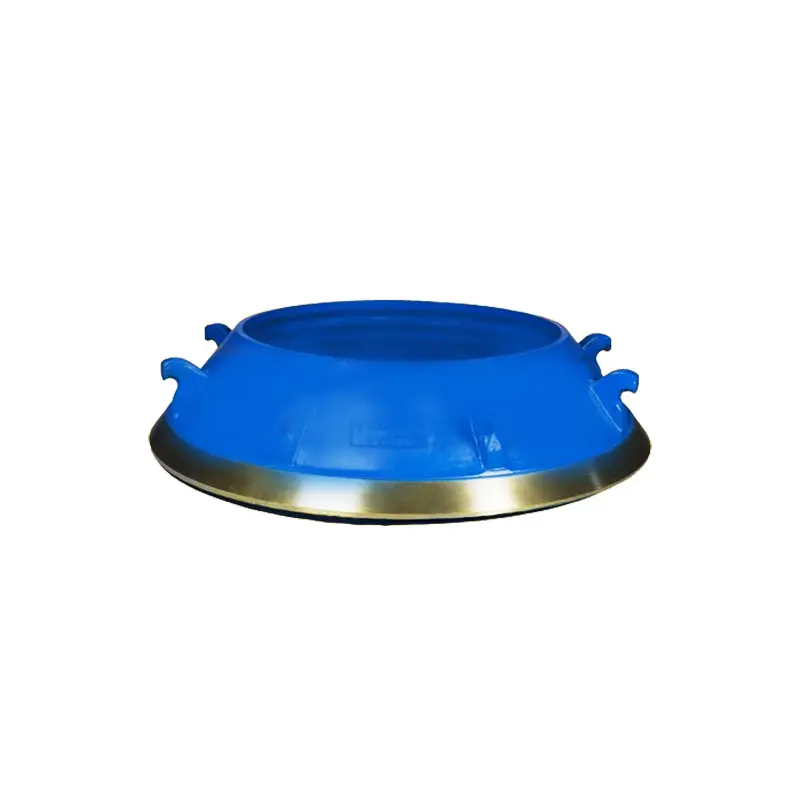

Product display