Affordable GP550 Cone Crusher Replacement Parts from Leading Manufacturers

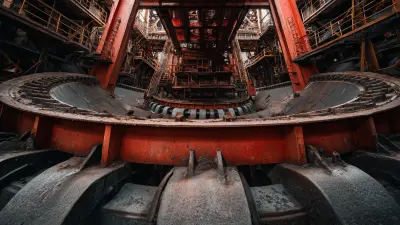

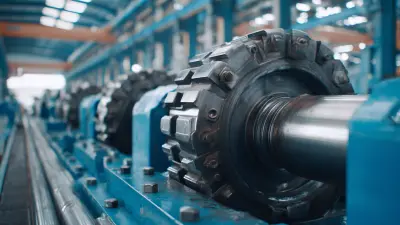

The Gp550 Cone Crusher Replacement Parts from Chengdu Zhixin Refractory Technology Co., Ltd. are crafted for outstanding durability and performance in rigorous mining and quarrying conditions. These components are designed to meet and exceed OEM specifications, ensuring an exact fit while being made from high-quality materials that offer excellent wear resistance. Focused on precision engineering, our replacement parts enhance the efficiency of your crushing operations and reduce downtime. Each item undergoes stringent quality control measures to guarantee reliability and longevity. Chengdu Zhixin Refractory Technology Co., Ltd. is dedicated to providing innovative solutions that boost productivity and cut operating costs. Opt for our Gp550 cone crusher replacement parts to maximize equipment performance, leading to greater profitability and improved operational success. Experience superior quality with our reliable replacements designed for the most demanding crushing applications.Ultimate Guide To Gp550 Cone Crusher Replacement Parts Now Trending More Than a Supplier - A Partner

In the dynamic world of mining and construction, the Gp550 cone crusher has become a cornerstone for high-performance operations. However, its effectiveness relies heavily on the quality of replacement parts. At Chengdu Zhixin Refractory Technology Co., Ltd., established in 2010, we specialize in crafting superior wear-resistant and high-temperature materials, alongside producing high manganese steel components essential for industrial machinery. Our commitment to excellence means that when you think of replacement parts for the Gp550, you are not merely selecting a supplier; you are choosing a partner invested in your success. While it is common to find suppliers offering generic parts, we understand the crucial role high-quality replacements play in maintaining the efficiency and longevity of your equipment. Our focus on research and innovation allows us to provide parts that not only meet but exceed industry standards. By collaborating with us, you gain access to a wealth of expertise and customized solutions designed to enhance your operations. This approach ensures that your machinery remains functional and competitive in an increasingly challenging market. As the demand for reliable and effective mining and construction equipment grows, partnering with a knowledgeable and dedicated manufacturer like Chengdu Zhixin Refractory Technology Co., Ltd. positions your business for success. Our comprehensive understanding of the Gp550 cone crusher and its replacement needs solidifies our role not just as a provider of parts, but as a strategic ally committed to advancing your operational capabilities. Together, we can navigate the complexities of the industry and drive growth through quality and performance.

Ultimate Guide To Gp550 Cone Crusher Replacement Parts Now Trending More Than a Supplier - A Partner

| Part Name | Material | Weight (kg) | Price (USD) | Availability |

|---|---|---|---|---|

| Mantle | High Manganese Steel | 300 | 1,200 | In Stock |

| Concave | High Manganese Steel | 280 | 1,150 | In Stock |

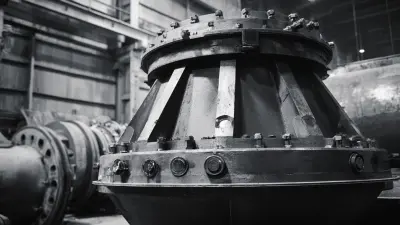

| Eccentric Bushing | Bronze | 150 | 400 | Available |

| Main Shaft | Alloy Steel | 180 | 800 | Made to Order |

| Hydraulic Cylinder | Steel | 220 | 600 | Low Stock |

The Ultimate Guide to Gp550 Cone Crusher Replacement Parts Where Service Meets Innovation Factory

L

Lucas Peterson

Quality is exceptional, and the after-sales service team was a pleasure to work with.

01 June 2025

C

Carter Cook

Great quality! The customer support was insightful and responsive to my needs.

30 May 2025

A

Anthony Diaz

Excellent product and service! The representatives were remarkable in their professionalism.

09 May 2025

A

Avery Adams

Impressive quality! The after-sales staff knew their stuff and were a great help.

30 June 2025

N

Natalie Brown

I had an excellent purchasing experience! Their team was professional and very helpful.

05 July 2025

N

Nathan Ryan

Outstanding quality product! The after-sales team’s support was excellent!

15 May 2025