High Manganese Steel Jaw Crusher Spare Parts - OEM Suppliers & Manufacturers

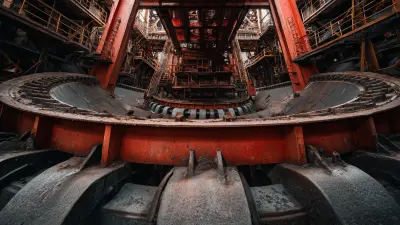

High Manganese Steel Casting Jaw Crusher Spare Parts by Chengdu Zhixin Refractory Technology Co., Ltd. are designed for outstanding durability and performance in the mining and construction industries. Made from premium manganese steel, these components are built to endure heavy impact and abrasion, ensuring long operational life and minimal downtime. Our jaw crusher spare parts are expertly crafted to fit a variety of jaw crusher models, enhancing crushing efficiency. The high manganese content allows the material to harden with each impact, making it particularly suitable for tough crushing conditions. Chengdu Zhixin Refractory Technology Co., Ltd. takes pride in advanced manufacturing practices and stringent quality control, guaranteeing that every part meets top industry standards. Rely on our high manganese steel spare parts for dependable performance and increased productivity, maximizing the lifespan of your equipment. Invest in durable and high-performing components that withstand the rigors of your operations.Where the Value Lies High Manganese Steel Casting Jaw Crusher Spare Parts Sets the Industry Standard From Concept to Delivery

In the competitive landscape of industrial machinery, the demand for durable and reliable components is ever-increasing. Chengdu Zhixin Refractory Technology Co., Ltd., established in 2010, is at the forefront of this evolution, specializing in high manganese steel casting jaw crusher spare parts. Our commitment to innovation and quality ensures that we set industry standards from concept to delivery, providing global purchasers with products that exceed expectations. Our high manganese steel casting is engineered to withstand extreme conditions, making it ideal for heavy-duty applications. With a focus on wear resistance and high-temperature tolerance, these components not only enhance the performance of Jaw Crushers but also extend their lifespan, reducing downtime and maintenance costs. We pride ourselves on our sophisticated manufacturing processes and rigorous quality control measures, ensuring that every product delivered meets the highest standards in the industry. Partnering with Chengdu Zhixin means choosing a supplier dedicated to excellence. Our experienced team collaborates closely with clients to understand their specific needs, delivering tailor-made solutions that drive efficiency and productivity. Join us in redefining industry standards and discover how our high manganese steel jaw crusher spare parts can add unparalleled value to your operations.

Where the Value Lies High Manganese Steel Casting Jaw Crusher Spare Parts Sets the Industry Standard From Concept to Delivery

| Part Name | Material | Hardness (HRC) | Weight (kg) | Application |

|---|---|---|---|---|

| Fixed Jaw Plate | High Manganese Steel | 14-18 | 150 | Primary Crushing |

| Moving Jaw Plate | High Manganese Steel | 14-18 | 180 | Primary Crushing |

| Side Liner | High Manganese Steel | 14-18 | 50 | Jaw Crusher Protection |

| Toggle Plate | Carbon Steel | 300 | 20 | Jaw Crusher Mechanism |

| Jaw Crusher Frame | Cast Steel | N/A | 1200 | Structural Support |

The Ultimate Guide to High Manganese Steel Casting Jaw Crusher Spare Parts Trusted by Pros Industry Leaders

B

Benjamin Clark

Truly impressed with the product’s durability. The staff’s dedication to customer service is noteworthy.

28 June 2025

J

Jack Young

Quality and service were both excellent. The team was very professional and knowledgeable.

09 May 2025

L

Liam Foster

Excellent service! The support team promptly answered all my questions with professionalism.

26 June 2025

I

Isaac Diaz

Great quality! The after-sales support team was helpful and efficient.

15 May 2025

V

Victoria Reyes

Wonderful product quality! Their customer care team was very responsive and supportive.

25 June 2025

J

Jordan Smith

Impressive experience! The product’s quality and the support team’s professionalism were both top-notch.

28 June 2025