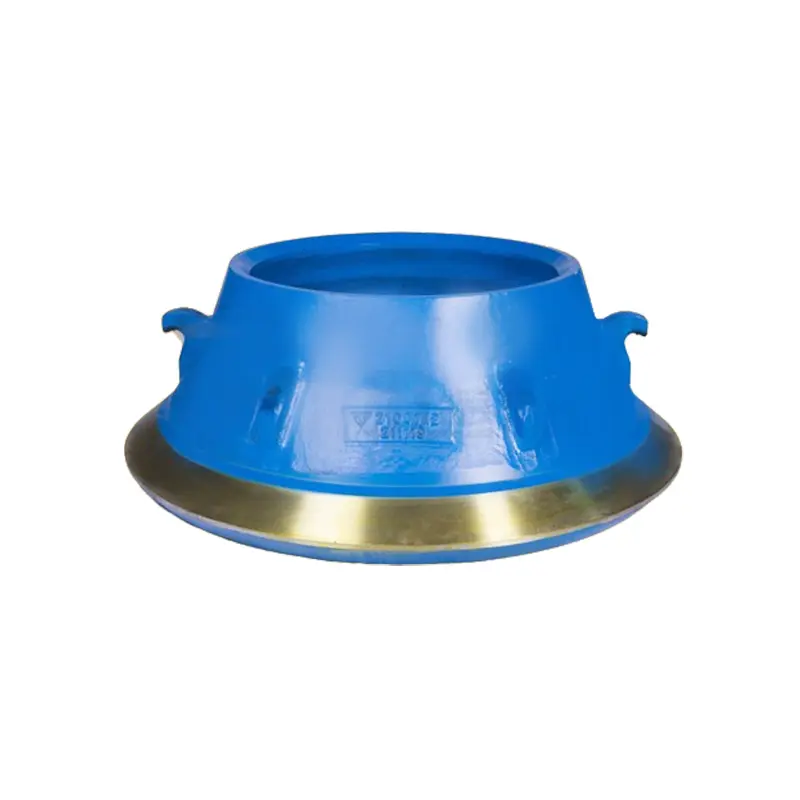

High manganese steel cone crusher concave and mantle

Features

Super wear resistance: The hardness of our cone crusher liners is more than HRC68°. Under large impact or contact stress, the surface layer is rapidly hardened, and the hardening index is 5-7 times higher than other materials, which greatly improves wear resistance.

Good toughness: The tensile strength of our cone liner exceeds 1500MPa and the impact toughness of the matrix exceeds 119J/cm2.

It has good plasticity and impact toughness, can withstand the strong impact force generated by the cone crusher when it is working, and is not prone to brittle fracture.

Long service life: More than twice that of conventional crusher liners, reducing your parts replacement time and improving crushing efficiency.

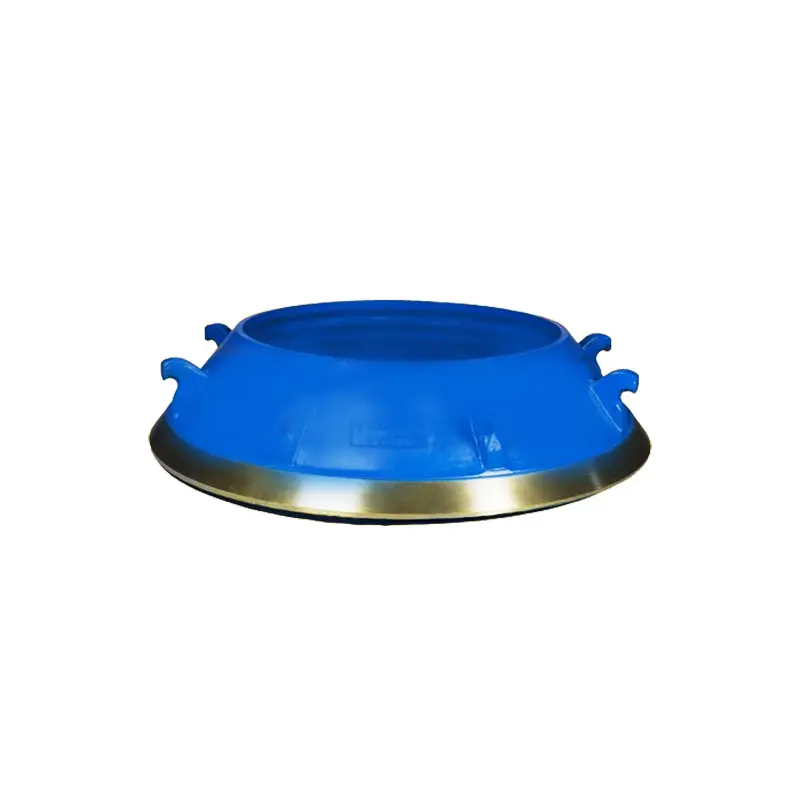

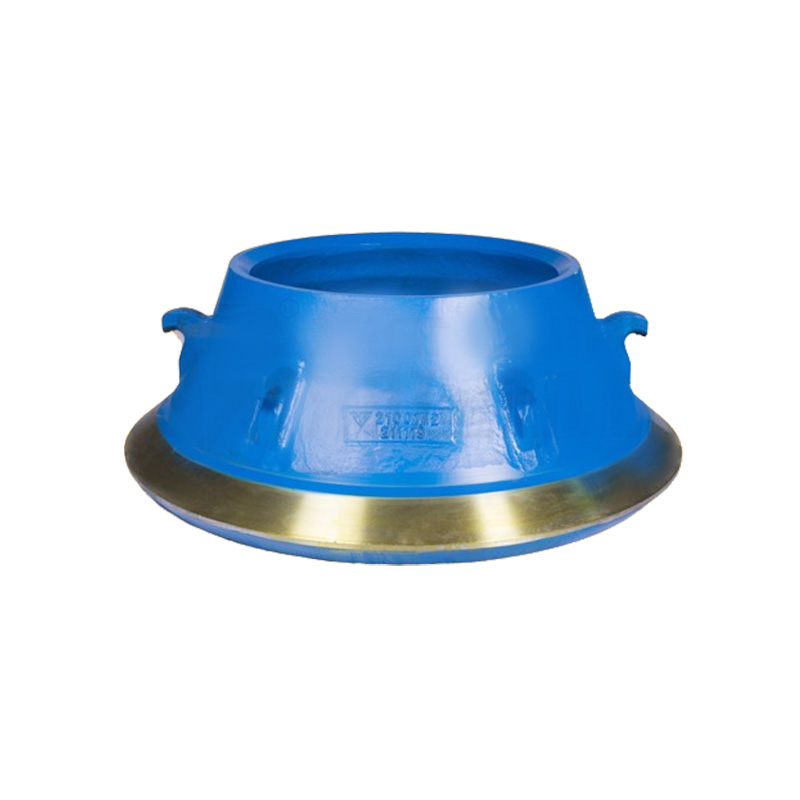

Product display

Working principle

The motor drives the eccentric sleeve to rotate, and the moving cone crusher liner (mantle) rotates and swings under the force of the eccentric sleeve. The high manganese steel crusher liner on the moving cone sometimes approaches and sometimes leaves the concave fixed on the adjustment sleeve, so that the material in the crushing chamber is continuously impacted, squeezed and bent and crushed.

Applicable models

Applicable models

Metso Series:

HP100, HP200, HP300, HP400, HP500, HP800, HP900.

MP800, MP1000, MP1250

GP100, GP200, GP300, GP500, GP11F, GP220

Symons 3ft, 4ft, 5ft, 7ft...

Snadvik series:

CH420, CH430, CH440, CH660, CH860, CH870

CS420, CS430, CS440, CS660

CG650, CG820

H2000, H3000, H4000, H6000, H8000

QH331, QH441

Sambo series:

SGC600, SGC900, SGC1200, SGC1650

SHC300, SHC500, SHC800

SMC200, SMC400, SMC600

SPC800, SPC1000

Other cone crushers:

In addition to the equipment models listed above, there are many other cone crushers. We can provide high-performance crusher liners for your equipment. You only need to provide photos and nameplates of the equipment and part numbers of wear parts. Of course, it would be better if you can provide drawings.

Maintenance and care

Regular inspection: Regularly stop the machine to check the wear of the crusher liners, observe whether the wear is uniform, whether there is severe local wear or cracks, etc.

Adjustment and installation: When installing the crusher lining, ensure that it is firmly installed and the gap between the concave and mantle is uniform and consistent.

Control materials: Strictly control the particle size of the material entering the crushing chamber to avoid excessively large or hard materials (especially metals) from entering the crushing chamber to prevent excessive wear or damage to the crusher lining.

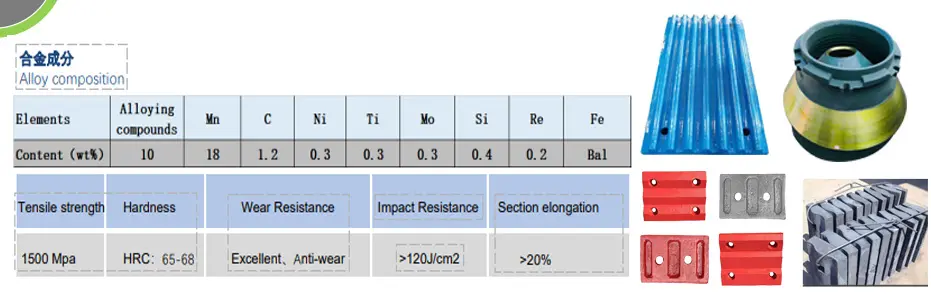

Material properties

Usually our crusher wear parts are based on Mn18Cr2, and we add our developed high-crystalline nano compounds (after more than 4 process treatments, they can be perfectly integrated into the base material). This makes the cast crusher wear parts have the following excellent characteristics: tensile strength greater than 1500MPa, impact resistance greater than 120J/cm2, and hardness greater than or equal to HRA85°.