In the quarry application of mining machinery, cone crusher is a key equipment

Working principle

Cone crusher liner is mainly composed of mantle (moving cone) and concave (fixed cone). The motor drives the eccentric sleeve to rotate through the pulley or coupling, and then makes the cone mantle do pendulum motion. When the ore enters the crushing chamber from the feed port, the distance between the concave and mantle changes continuously. When approaching, the ore is crushed by extrusion, bending and impact. When the cone mantle leaves, the crushed ore moves downward under the action of gravity and is continuously crushed until the particle size meets the requirements and is discharged from the discharge port.

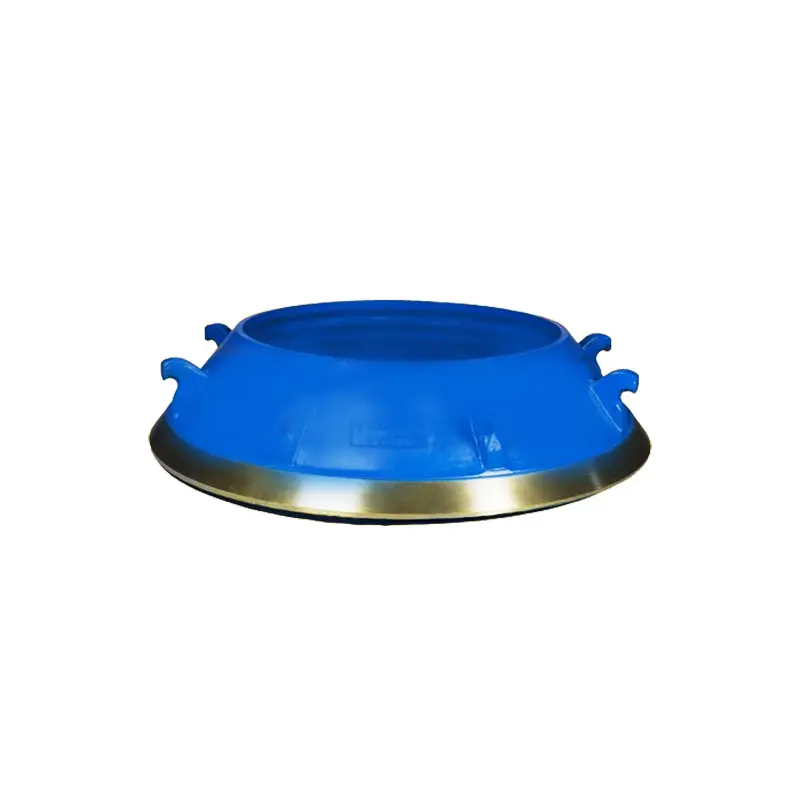

Product display

Structural features

Advantages of Zhixin cone crusher liner

Advantages of Zhixin cone crusher liner

1. The use of more than 40 kinds of rare metals and high manganese steel to combine in a progressive and perfect way makes the wear resistance of our cone crusher liner significantly higher than that of conventional wear-resistant parts, and the service life is 2-3 times that of conventional products.

2. The Ministry of Science and Technology of China authoritatively certified that the tensile strength of our crusher wear-resistant parts is greater than 1500MPa, the hardness is greater than HRC68 degrees, and the impact toughness is greater than 119J/square centimeter. Our cone liner has both strength and toughness, and the key is super wear resistance.

3. We dare to promise that if it does not reach twice the service life of your previous conventional wear-resistant parts, we will refund the full amount. We can write the clause in the invoice!

The main functions of the cone liner include:

The main functions of the cone liner include:

1. Protect equipment

The gaps between the concave and mantle prevent the crusher cylinder from directly bearing the impact and wear of the material, which plays a buffering role and reduces the loss of the equipment body.

2. Improve crushing efficiency

By adjusting the working state of the grinding body, the material crushing path is optimized, the crushing efficiency is improved, and the loss of the medium and liner is reduced.

3. Ensure uniform particle size

Control the particle size of the discharge material to avoid over-crushing or under-crushing, and ensure the stable quality of the finished product.

4. Extend the life of the equipment

Reasonable selection of material and shape design (such as high manganese steel, alloy steel, etc.) can significantly improve wear resistance and reduce replacement frequency of cone crusher liners.

Material characteristics

· High manganese steel: the most widely used. Generally the basic material of our cone crusher liners is Mn18Cr2, this material has good toughness. When it is impacted and rubbed by ores, the surface will produce work hardening, and the hardness can be improved to a certain extent, so it has good wear-resistance.

· New composite materials: Crushing lining made of materials such as high chromium cast iron are also gradually emerging. High chromium cast iron has high hardness and excellent wear resistance. It is suitable for crushing operations of some high-hardness ores and can effectively extend the service life of the crushing lining.

· Ore characteristics: The higher the hardness of the ore and the stronger the abrasiveness, the faster the wear rate of the crushing lining. For example, the wear of the crushing lining when crushing granite will be much faster than when crushing limestone.

· Equipment operating parameters: If the feeding speed of the ores is too fast and the feeding particle size is uneven, the load on the crushing liner will be unstable, resulting in increased local wear and shortening of the service life.

· Equipment maintenance: Regular maintenance of the crusher, including timely cleaning of the crushing chamber and lubrication of related parts, can reduce abnormal wear of the crushing liner and extend its service life.

Installation and replacement

Installation: During installation, ensure that the cone crusher concave fits tightly with the cone crusher mantle. Generally, special bolts and other connectors are used for tightening, and the installation accuracy must be ensured to avoid installation deviation and other situations that affect the normal operation of the crusher.

Replacement: When the crusher liner is worn to a certain extent, affecting the crushing effect (such as the product particle size does not meet the requirements) or when it is damaged, it needs to be replaced in time. The replacement process must be carried out strictly in accordance with the equipment's operating manual to ensure that the new crusher liner is installed correctly.