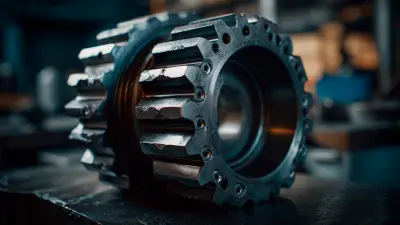

Quality Jaw Crusher Components from Leading ODM Manufacturers and Exporters

Chengdu Zhixin Refractory Technology Co., Ltd. offers a comprehensive selection of high-quality Jaw Crusher Components designed for optimal performance in mining and construction. Our product range includes durable jaw plates, toggle plates, and frames, all engineered from advanced materials to withstand harsh operating conditions. Each component is designed to minimize wear and enhance efficiency, resulting in reduced downtime and lower maintenance costs. With a strong commitment to quality, all products go through strict testing and inspection to ensure they meet international standards for reliability and safety. Partner with Chengdu Zhixin for dependable jaw crusher components that enhance productivity and operational success.

Expert Tips For Jaw Crusher Components More Than a Supplier - A Partner Industry Giant

In the competitive landscape of industrial machinery, particularly in the mining and construction sectors, the reliance on durable and high-performance equipment has never been greater. Chengdu Zhixin Refractory Technology Co., Ltd., established in 2010, is at the forefront of this industry, specializing in research and production of wear-resistant materials and high manganese steel components. As global purchasing professionals seek reliable partners, the emphasis should be placed not only on product quality but also on the value of collaboration and expertise in optimizing machinery performance. When considering suppliers for jaw crusher components, it’s crucial to partner with a provider that understands the intricate balance between innovation and practical application. Chengdu Zhixin exemplifies this with its commitment to developing specialized materials designed to withstand extreme conditions, ensuring longevity and efficiency in jaw crushers. Our components are engineered not just to meet industry standards but to exceed them, thereby facilitating enhanced operational productivity and minimizing downtime for our clients. By choosing Chengdu Zhixin as a partner rather than merely a supplier, companies gain access to expert insights and tailored solutions that align with their specific needs. Our team of specialists works closely with clients to assess their requirements and challenges, providing customized support that goes beyond the transactional nature of traditional supply relationships. In the dynamic field of heavy machinery, this partnership approach ensures that you have the right solutions in place to drive your operations forward successfully.

Expert Tips For Jaw Crusher Components More Than a Supplier - A Partner Industry Giant

| Component | Material | Application | Maintenance Tips |

|---|---|---|---|

| Jaw Plates | High Manganese Steel | Primary Crushing | Regular inspection for wear; replace when worn to 20mm |

| Cheek Plates | Ni-Hard Cast Iron | Support for Jaw Plates | Inspect for cracks and replace if necessary |

| Toggle Plate | Steel | Force Distribution | Check for bending and integrity |

| Flywheel | Cast Iron | Stabilizes Motion | Inspect for cracks; lubricate bearings |

| Bearing | Bronze | Supports Movement | Regular lubrication; check alignment |

Simple Ways To Jaw Crusher Components Sets the Industry Standard Industry Giant

M

Megan Thomas

Top-quality product with a responsive support team. They made the whole experience seamless!

05 June 2025

M

Madison Allen

This product is a must-have! The customer service exceeded my expectations in terms of response time.

24 June 2025

O

Oliver Collins

I am very impressed! The quality is unmatched and the customer care team was very informative.

21 May 2025

S

Sophie Brooks

Highly impressed with the product! The after-sales support team exceeded my expectations.

19 May 2025

A

Anthony Diaz

Excellent product and service! The representatives were remarkable in their professionalism.

09 May 2025

E

Emma Ramirez

The craftsmanship is excellent! I appreciated the professionalism of the support team.

12 May 2025