OEM Jaw Crusher Liners - Leading Exporter & Supplier of Quality Parts for Your Needs

Jaw Crusher Liners from Chengdu Zhixin Refractory Technology Co., Ltd. are meticulously crafted for durability and peak performance in demanding crushing applications. Constructed from high-quality materials, these liners are designed to resist extreme wear, ensuring significant longevity and reliability. Their precise engineering enhances jaw crusher efficiency, reducing both downtime and maintenance costs. Available in a variety of specifications to accommodate different jaw crusher models, our liners suit various industries, including mining, construction, and aggregate production. With advanced alloy compositions, our products provide exceptional abrasion and impact resistance, resulting in improved crushing capacity and product quality. Trust Chengdu Zhixin Refractory Technology Co., Ltd. for superior solutions tailored to elevate your operational performance.How To Decide Between Jaw Crusher Liners Is The Best Dominates

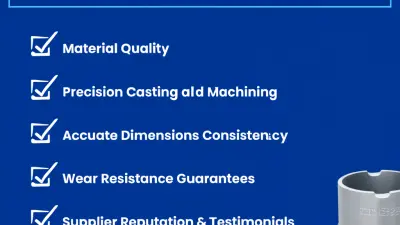

When it comes to optimizing the performance of your crushing equipment, selecting the right jaw crusher liners is crucial. Given the pivotal role these components play in the efficiency and longevity of machinery, how do you decide which type of liners will best meet your needs? Chengdu Zhixin Refractory Technology Co., Ltd., established in 2010, specializes in high-quality wear-resistant materials and high manganese steel components for the machinery and equipment industry. Our expertise allows us to guide you through the selection process effectively. The first consideration is the material composition of the liners themselves. High manganese steel liners are renowned for their ability to absorb shock and withstand high temperatures, making them ideal for demanding environments. Depending on your specific applications, you can choose between different grades and thicknesses, impacting both performance and wear rates. Additionally, understanding the crushing materials—whether you are dealing with softer or harder aggregates—can help you select liners that enhance productivity while reducing downtime and replacement costs. Finally, factor in the design and fit of the liners within your existing jaw crusher system. A well-fitted liner not only improves the crushing efficiency but also extends the lifespan of both the liners and your equipment. At Chengdu Zhixin, we are committed to providing tailored solutions to global buyers, ensuring you make informed decisions that lead to optimal operational performance. Choose wisely, and you will see significant improvements in your machinery's effectiveness and durability.

How To Decide Between Jaw Crusher Liners Is The Best Dominates

| Liner Material | Hardness (Rockwell) | Wear Resistance | Impact Resistance | Cost (per ton) |

|---|---|---|---|---|

| Hadfield Steel | 58-62 | High | Medium | $300 |

| Mn Steel | 50-55 | Medium | High | $250 |

| Alloy Steel | 55-60 | Medium | Medium | $280 |

| Ceramic Composite | 60-65 | Very High | Low | $450 |

| Ultra-high Molecular Weight Polyethylene | N/A | Low | Medium | $200 |

Practical Methods To Jaw Crusher Liners Dominates Sets the Industry Standard

J

Jonathan White

Exceptional product quality! It’s clear that they stand behind their product with a strong after-sales service.

19 May 2025

C

Christopher Anderson

Very satisfied with my purchase! The customer service team displayed exceptional professionalism.

01 June 2025

G

Grace Gonzalez

Exceedingly satisfied with my purchase! Their customer support team is professional and very helpful.

09 May 2025

G

Grace Ward

Remarkable quality! The customer support team was incredibly professional and helpful.

12 June 2025

O

Oliver Young

The quality is exceptional! The customer service team is knowledgeable and professional.

19 June 2025

C

Cameron Hill

Impressive product! Their commitment to customer service during the follow-up was remarkable.

20 May 2025