High-Quality ODM Jaw Crusher Parts for Reliable Factory Performance

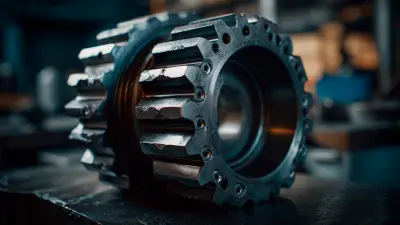

Chengdu Zhixin Refractory Technology Co., Ltd. is a trusted provider of high-quality Jaw Crusher Parts designed to enhance the performance and longevity of crushing operations. Our product lineup features a variety of components, including jaw plates, toggle plates, and cheek plates, all made from robust materials that can withstand harsh conditions. Engineered for precision and reliability, each part optimizes performance and minimizes downtime, making them ideal for the mining, construction, and aggregate industries. Our jaw crusher parts undergo rigorous testing for quality and compatibility with leading crusher brands, ensuring seamless integration into your existing systems. Partnering with us means benefiting from innovative solutions and dedicated customer support tailored to meet your specific requirements. Rely on Chengdu Zhixin for the durability and performance essential to keep your operations running efficiently.Smart Ways To Jaw Crusher Parts Manufacturer Is The Best

In the competitive world of industrial machinery, choosing the right supplier for jaw crusher parts is critical for ensuring operational efficiency and minimizing downtime. As a leading manufacturer based in Chengdu, Chengdu Zhixin Refractory Technology Co., Ltd. has established itself at the forefront of this sector since its inception in 2010. With a dedicated focus on the research and production of special wear-resistant and high-temperature resistant materials, along with high manganese steel components, our offerings are designed to meet the rigorous demands of various industries. One of the smart ways we differentiate ourselves is through our commitment to quality and innovation. By leveraging advanced technology and materials science, our jaw crusher parts provide superior durability and performance. This not only extends the lifespan of your equipment but also translates into significant cost savings over time. Moreover, our expertise in producing high manganese steel machinery ensures maximum resistance to wear and tear, further boosting your operational productivity. Additionally, we understand that global buyers seek reliable partners who can provide consistent supply and excellent customer support. At Chengdu Zhixin, we pride ourselves on our responsive service and ability to cater to customized needs, ensuring that our products fit seamlessly into your existing operations. By choosing us as your jaw crusher parts manufacturer, you are not just investing in components; you are investing in a partnership that prioritizes your success.

Smart Ways To Jaw Crusher Parts Manufacturer Is The Best

| Part Name | Material | Durability (Hours) | Cost (USD) | Supplier Rating |

|---|---|---|---|---|

| Jaw Plate | High Manganese Steel | 400 | 150 | 4.5/5 |

| Toggle Plate | Cast Iron | 300 | 50 | 4.0/5 |

| Cheek Plates | Manganese Alloy | 350 | 75 | 4.2/5 |

| Frame | Welded Steel | 500 | 300 | 4.8/5 |

| Bearing | Bronze | 600 | 200 | 4.7/5 |

Finding Your Perfect Match Jaw Crusher Parts Manufacturer From Concept to Delivery

L

Laura Wright

The quality of this product is exceptional. The after-sales service team went above and beyond to answer my questions.

07 July 2025

A

Ava Nelson

The product quality is amazing! Customer support was efficient and incredibly friendly.

28 June 2025

M

Mikayla Phillips

I had an excellent purchasing experience! Their customer support was both professional and friendly.

22 May 2025

O

Osman Ford

Incredible quality! I was impressed with the dedication of the after-sales support team.

02 June 2025

E

Ethan Lewis

The product is fantastic! The support team was very responsive and professional.

21 June 2025

S

Sophia Harris

The craftsmanship is truly impressive! The after-sales support was above and beyond.

02 July 2025