Wholesale Mantle Bowl Liners for S4800 Cone Crusher - Quality Manufacturers & Supplier

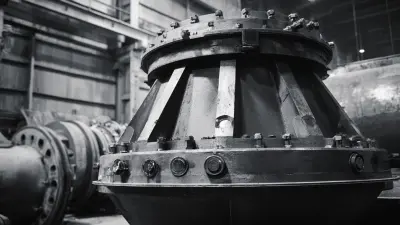

The Mantle Bowl Liner for the S4800 Cone Crusher is an essential component that significantly improves the efficiency and lifespan of crushing operations across various sectors. Manufactured by Chengdu Zhixin Refractory Technology Co., Ltd., this premium liner is engineered for exceptional performance under challenging conditions. With its outstanding wear resistance, it can endure heavy-duty use while ensuring optimal crushing ratios and minimizing downtime caused by wear. The precise engineering of this product not only enhances productivity but also reduces maintenance costs. Chengdu Zhixin Refractory Technology Co., Ltd. is dedicated to quality and innovation, providing solutions that support the dynamic needs of the mining and aggregate industries—keeping your operations efficient and reliable with high-performance components.Quick Tips To Mantle Bowl Liner For S4800 Cone Crusher Supplies the World’s Top Brands Delivers Unmatched Quality

When it comes to maintaining the longevity and efficiency of your S4800 cone crusher, utilizing high-quality mantle Bowl Liners is crucial. At Chengdu Zhixin Refractory Technology Co., Ltd., established in 2010, we specialize in the production of wear-resistant and high-temperature resistant materials tailored for the mining and machinery industries. Our commitment to quality ensures that our mantle bowl liners not only meet but exceed the stringent requirements set by the world’s top brands. Our liners are crafted from high manganese steel, renowned for its ability to withstand extreme wear and high temperatures. With a focus on research and innovation, we guarantee that each product undergoes rigorous testing to deliver unmatched durability and performance. When you choose our mantle bowl liners, you are choosing a product backed by years of expertise and a dedication to excellence, ensuring that your equipment runs smoothly and efficiently, reducing downtime and maintenance costs. Partnering with Chengdu Zhixin Refractory Technology means investing in superior materials that enhance operational performance. We are ready to support global buyers with our advanced technologies and reliable products. Experience the difference in quality and longevity with our S4800 cone crusher mantle bowl liners – an essential choice for any serious operation seeking to optimize their productivity.

Quick Tips To Mantle Bowl Liner For S4800 Cone Crusher Supplies the World’s Top Brands Delivers Unmatched Quality

| Tip # | Tip Description | Expected Outcome | Common Issues |

|---|---|---|---|

| 1 | Ensure proper bowl liner selection to match the cone profile. | Improved crushing efficiency and product shape. | Mismatch leading to excessive wear. |

| 2 | Regular monitoring of wear indicators on liners. | Extended lifespan of liners. | Unexpected downtime due to wear. |

| 3 | Implement a consistent maintenance schedule. | Reduced risk of failures and increased reliability. | Potential for catastrophic failure. |

| 4 | Use high-quality materials for liners and bowls. | Better durability and resistance to wear. | Frequent replacements leading to cost increases. |

| 5 | Train operators on optimal feeding techniques. | Enhanced throughput and reduced blockages. | Inefficient operation resulting in lower output. |

China Top Mantle Bowl Liner For S4800 Cone Crusher Service Backed by Expertise Guarantees Peak Performance

B

Brandon Lee

Exceptional service! After my purchase, the support team guided me perfectly through the setup.

14 May 2025

E

Ella Adams

I had a wonderful experience! The product quality is fabulous, and the after-sales team is super helpful.

30 June 2025

G

Grace Gonzalez

Exceedingly satisfied with my purchase! Their customer support team is professional and very helpful.

09 May 2025

M

Michael Evans

This product exceeded my expectations! The after-sales support was exceptional.

20 May 2025

K

Kyle Evans

I am very pleased with my purchase! Their supportive staff made all the difference.

17 June 2025

I

Isaac Diaz

Great quality! The after-sales support team was helpful and efficient.

15 May 2025