Affordable Maxtrak 1000 Cone Crusher Liners from Reliable Exporters & Suppliers

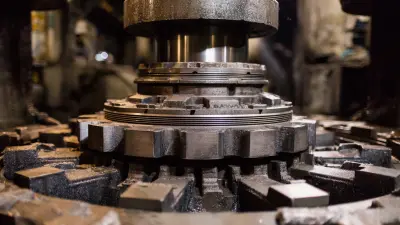

The Maxtrak 1000 Cone Crusher Liners, produced by Chengdu Zhixin Refractory Technology Co., Ltd., are engineered for outstanding durability and performance in tough crushing environments. Made from premium materials, these liners offer excellent wear resistance and extended lifespan, ensuring reliable output and minimizing downtime. Designed specifically for the Maxtrak 1000 model, they enhance crusher efficiency by maximizing the crushing area and reducing damage risks. With precise manufacturing that adheres to rigorous quality standards, these liners reinforce the company's dedication to excellence. Ideal for the mining, construction, and recycling industries, Maxtrak 1000 Cone Crusher Liners deliver improved productivity and lower operational costs, merging innovation with resilience for optimal crushing operations.Where the Value Lies Maxtrak 1000 Cone Crusher Liners Ahead of the Curve Industry Leaders

In the competitive landscape of mining and construction, the importance of durable and efficient equipment cannot be overstated, especially when it comes to cone crushers like the Maxtrak 1000. At Chengdu Zhixin Refractory Technology Co., Ltd., we understand that the true value of these machines lies in their components, particularly the liners. Our advanced liners are designed to withstand extreme wear and high-temperature environments, ensuring that they not only meet but exceed industry standards. Established in 2010, our company specializes in the research and production of high manganese steel and wear-resistant materials. By focusing on the unique demands of industries that rely heavily on machinery, we have positioned ourselves as leaders in providing high-quality products that enhance operational efficiency. The Maxtrak 1000 cone crusher liners we offer are meticulously engineered to offer superior performance, extending the life of the crusher and reducing downtime, thus providing our global customers with exceptional return on investment. Companies that prioritize quality and innovation find great motivation in partnering with us. By aligning with Chengdu Zhixin, you gain access to cutting-edge technology and reliable support, ensuring your operations remain ahead of the curve. Whether you're seeking to boost productivity or enhance the longevity of your equipment, our cone crusher liners stand as a testament to the value we provide for industry leaders worldwide.

Where the Value Lies: Maxtrak 1000 Cone Crusher Liners Ahead of the Curve Industry Leaders

| Dimension | Material Type | Average Lifespan (hours) | Wear Rate (mm/100 hours) | Cost per Unit ($) |

|---|---|---|---|---|

| Standard Liner | Manganese Steel | 850 | 0.6 | 750 |

| Premium Liner | High Carbon Steel | 950 | 0.4 | 950 |

| Heavy Duty Liner | Alloy Steel | 780 | 0.8 | 850 |

| Extended Liner | Chromium Steel | 1200 | 0.3 | 1100 |

| Custom Liner | Composite Materials | 1500 | 0.2 | 1300 |

Today's Choice of Maxtrak 1000 Cone Crusher Liners Your End-to-End Solution More Than a Supplier - A Partner

M

Michael Thompson

The quality of the product exceeded my expectations. The support team was incredibly responsive and helpful throughout the purchasing process.

26 May 2025

E

Emily Davis

I was truly impressed by the quality of the product. The customer service was remarkably efficient and supportive.

02 June 2025

M

Madison Allen

This product is a must-have! The customer service exceeded my expectations in terms of response time.

24 June 2025

C

Carter Cook

Great quality! The customer support was insightful and responsive to my needs.

30 May 2025

I

Ian Wright

Highly recommend this product! The after-sales service was really phenomenal.

28 May 2025

E

Eva Sanchez

The product is of great quality! The customer service team was very knowledgeable.

28 June 2025