Metso Wear Parts OEM Supplier for Superior Performance and Reliability

Metso Wear Parts are designed for exceptional durability and performance across various industrial applications, enhancing the longevity and efficiency of your machinery. Produced by Chengdu Zhixin Refractory Technology Co., Ltd., these components are crafted from advanced materials and the latest technology to endure extreme conditions, minimizing downtime and maintenance expenses. Our product line includes liners, crusher parts, and essential components to optimize equipment performance. Every part undergoes stringent testing to ensure compliance with the highest industry standards, delivering reliability and superior wear resistance. With a commitment to customer satisfaction, we offer customized solutions tailored to your specific needs, facilitating seamless integration with existing systems. Rely on Metso Wear Parts from Chengdu Zhixin Refractory Technology Co., Ltd. to boost productivity and prolong the operational life of your equipment. Trust our expertise and experience to keep your operations running efficiently.7 Key Tips To Metso Wear Parts Custom Solutions, Is The Best

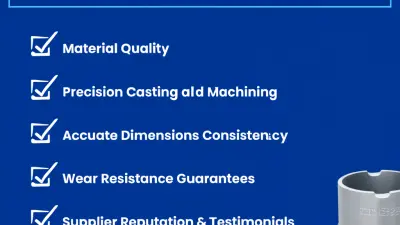

In today's competitive industrial landscape, choosing the right supplier for Metso wear parts can significantly impact efficiency and productivity. Chengdu Zhixin Refractory Technology Co., Ltd., established in 2010, specializes in the research and production of wear-resistant and high-temperature resistant materials, making it an ideal partner for custom solutions in high manganese steel machinery and equipment. Here are seven key tips to consider when seeking the best Metso wear parts tailored to your needs. First, prioritize collaboration with manufacturers who have a proven track record and industry expertise. Chengdu Zhixin's commitment to innovation ensures that their custom solutions align with the unique demands of your operations. Additionally, understanding the specific wear and temperature conditions your machinery faces is crucial. A reliable supplier will work with you to analyze these conditions and propose materials that enhance longevity and performance. Furthermore, don't underestimate the importance of quality assurance and testing. A trustworthy partner will conduct rigorous testing on their wear parts, ensuring they meet the highest industry standards. Finally, consider the supplier's ability to provide timely support and technical assistance. Chengdu Zhixin prides itself on its proactive customer service approach, ensuring that clients receive not only top-quality products but also the guidance needed for optimal usage. By focusing on these essential factors, global buyers can secure the best custom solutions for their Metso wear parts needs.

7 Key Tips To Metso Wear Parts Custom Solutions, Is The Best

| Tip Number | Tip Title | Description | Benefits |

|---|---|---|---|

| 1 | Understand Your Needs | Identify and articulate your specific requirements for wear parts. | Ensures the right specifications are met. |

| 2 | Consult Technical Experts | Engage with engineers or specialists to assess the best materials. | Increases efficiency and longevity of wear parts. |

| 3 | Customization Options | Explore tailor-made solutions suited to particular applications. | Enhances functionality and fit. |

| 4 | Quality Assurance | Make sure that the wear parts are tested for quality and durability. | Reduces downtime and maintenance costs. |

| 5 | Consider Production Time | Factor in lead times while placing custom orders. | Ensures timely availability of parts. |

| 6 | Supplier Reputation | Research the reliability and reviews of potential suppliers. | Guarantees better service and products. |

| 7 | Post-Purchase Support | Ensure that the supplier offers solid post-sale support. | Provides assistance if modifications or replacements are needed. |

Why Professionals Prefer Metso Wear Parts Where Innovation Meets 2025 More Than a Supplier - A Partner

M

Michael Thompson

The quality of the product exceeded my expectations. The support team was incredibly responsive and helpful throughout the purchasing process.

26 May 2025

J

Jessica Wilson

The product is fantastic! I appreciate how attentive the support staff was with my inquiries.

15 June 2025

C

Chloe Morgan

The quality truly impressed me! The support staff was professional and very helpful.

28 June 2025

A

Aaron Baker

Very high-quality item! The professional service from the after-sales team was commendable.

05 June 2025

J

Jordan Smith

Impressive experience! The product’s quality and the support team’s professionalism were both top-notch.

28 June 2025

C

Christian Reed

Extremely satisfied! The after-sales support exceeded my expectations completely.

04 July 2025