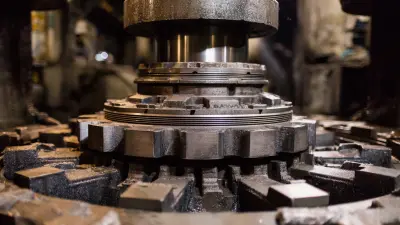

Top Cone Crusher Bowl Liners from Leading ODM Manufacturers for Optimal Wear Resistance

The Cone Crusher Bowl Liner plays an essential role in ensuring the efficiency and durability of rock crushing operations. Made from top-grade materials, our Bowl Liners are engineered to endure the intense wear and tear from crushing hard materials. Chengdu Zhixin Refractory Technology Co., Ltd. specializes in producing robust bowl liners that improve cone crusher performance across various sectors, including mining, construction, and recycling. With a focus on precision engineering and quality assurance, our bowl liners guarantee an optimal fit and functionality, leading to minimized downtime and enhanced productivity. We provide a diverse range of options compatible with different cone crusher models, ensuring peak performance. By selecting our bowl liners, customers benefit from superior wear resistance, prolonged service life, and greater crushing efficiency, making Chengdu Zhixin Refractory Technology Co., Ltd. a trusted source for essential wear parts vital for optimal machinery operation.How To Identify Most Important Wear Parts Cone Crusher Bowl Liner Manufacturer Service Backed by Expertise

When it comes to enhancing the efficiency and longevity of cone crushers, identifying the most important wear parts, particularly the bowl liners, is crucial. Chengdu Zhixin Refractory Technology Co., Ltd., established in 2010, has carved a niche in the production of high-quality, wear-resistant materials specifically for the high manganese steel machinery and equipment industry. Our expertise allows us to understand the intricacies of wear part performance in various operational environments, ensuring our products meet the demands of global clients. Bowl liners are essential components that face significant wear due to constant friction and pressure in crushing operations. Selecting the right bowl liner not only reduces maintenance costs but also improves the overall efficiency of your machinery. At Chengdu Zhixin, we leverage advanced research and production techniques to manufacture bowl liners that offer exceptional durability and resistance to high temperatures, making them ideal for industries ranging from mining to recycling. Our commitment to quality and innovation, backed by years of specialized knowledge, enables us to provide tailored solutions that fit the unique needs of our clients. By partnering with Chengdu Zhixin, procurement managers can be assured of sourcing components that enhance production workflows while minimizing downtime. Our team’s expertise in wear-resistant materials guarantees a reliable performance that meets international standards. Invest in quality, and let us help you navigate the complexities of wear parts procurement, ensuring your equipment operates at peak efficiency.

How To Identify Most Important Wear Parts Cone Crusher Bowl Liner Manufacturer Service Backed by Expertise

| Part Name | Material | Lifespan (Hours) | Application Area | Manufacturer Expertise Level |

|---|---|---|---|---|

| Bowl Liner | Mn Steel | 2000 | Secondary Crushing | High |

| Concave | High Alloy Steel | 1800 | Tertiary Crushing | Moderate |

| Mantle | Manganese | 2200 | Primary Crushing | High |

| Cone Head | Alloy Steel | 1500 | Granite Crushing | Moderate |

How To find Most Important Wear Parts Cone Crusher Bowl Liner Is The Best Your End-to-End Solution

L

Linda Rodriguez

I’m impressed by the professionalism of the customer service staff. They provided excellent guidance and support post-purchase.

04 June 2025

Z

Zoe Patterson

Outstanding quality! Their dedicated support team made the after-sale experience effortless.

06 June 2025

S

Samuel Torres

Product quality is fantastic, and their after-sales support is incredibly commendable.

18 June 2025

C

Carter Cook

Great quality! The customer support was insightful and responsive to my needs.

30 May 2025

A

Avery Adams

Impressive quality! The after-sales staff knew their stuff and were a great help.

30 June 2025

J

James Torres

Exceptional product quality and a very professional customer service team to back it up!

29 June 2025