News

Innovator of wear-resistant technology: How Chengdu Zhixin Refractory Technology reshapes the performance of crusher linings

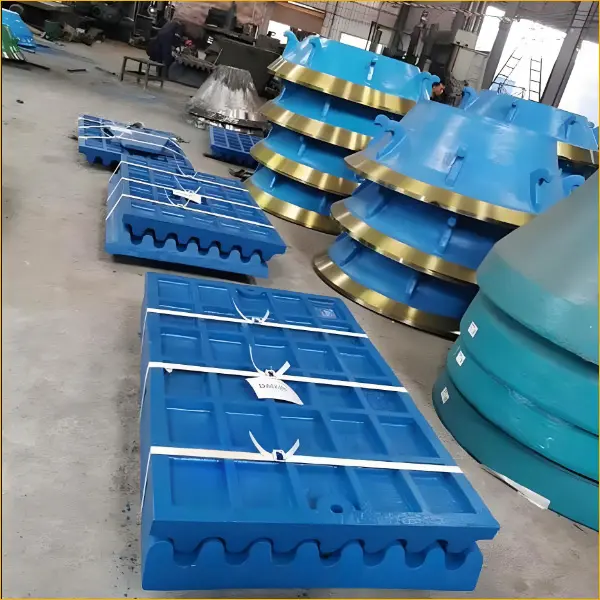

In industries such as mining, cement and building materials, crushers, as core equipment, undertake heavy material crushing tasks. As a component that directly contacts the material, the wear resistance of the crusher lining directly affects the working efficiency and production cost of the equipment. Chengdu Zhixin Refractory Technology Co., Ltd., with its excellent wear-resistant material research and development capabilities, produces compound crusher wear-resistant parts with a service life of more than twice that of conventional products under the same working conditions, bringing revolutionary changes to the industry.

Improve crushing efficiency and extend service life - Chengdu Zhixin Refractory Technology creates high-quality cone crusher linings for you.

In mining, building materials, metallurgy and other industries, cone crushers are one of the core crushing equipment, and their working efficiency and stability directly affect the operating cost and production capacity of the production line. As a key wear-resistant component of the crusher, the service life and performance of the liner are crucial. Chengdu Zhixin Refractory Technology Co., Ltd. focuses on the research and development and production of high-wear-resistant crusher accessories. With advanced material technology and mature process experience, it provides the industry with high-performance cone Crusher Liners. This article explains the technical essentials of filling liner fillers for cone crushers.

Importance of choosing the right cone crusher lining

In the crushing industry, such as quarrying, aggregate production, cement production, mining, etc., cone crusher is one of the core equipment for crushing hard rock, ore and construction aggregate, and is often used for secondary crushing. Wear-resistant cone crusher lining, as its key vulnerable parts, directly affects crushing efficiency, operating costs and equipment life. Choosing the right cone crusher liner is particularly important because it not only improves productivity but also reduces downtime and maintenance costs.

The key role of metal prevention in crushing

Importance of wear parts and significance of replacement

Replacing the wear parts (jaw crusher jaw plate) of the jaw crusher is the key to ensure the continuous and efficient operation of the equipment. In the jaw crusher, the liner, thrust plate, eccentric shaft and other parts need to be replaced regularly due to long-term wear. Mastering the replacement points of these wear parts is crucial to extending the overall life of the equipment. Next, we will explore the key points in the replacement process of these wear parts.

Super wear-resistant jaw crusher jaw plate: a wise choice to improve crushing efficiency and reduce operating costs

In mining, building materials, metallurgy, glass, stone and other industries, jaw crusher is the core equipment for primary crushing, and its performance directly affects production efficiency and operating costs. The core wear-resistant component of the jaw crusher, the jaw plate, is the key factor in determining the life of the equipment and the crushing effect. Chengdu Zhixin Refractory Technology Co., Ltd., relying on advanced casting technology and material research and development capabilities, has launched super wear-resistant jaw Crusher Jaw Plates, whose service life can reach 2-3 times that of conventional products, greatly improving crushing efficiency, reducing the frequency of downtime and replacement, while saving customers transportation costs and tariffs, etc., creating higher economic benefits for customers.

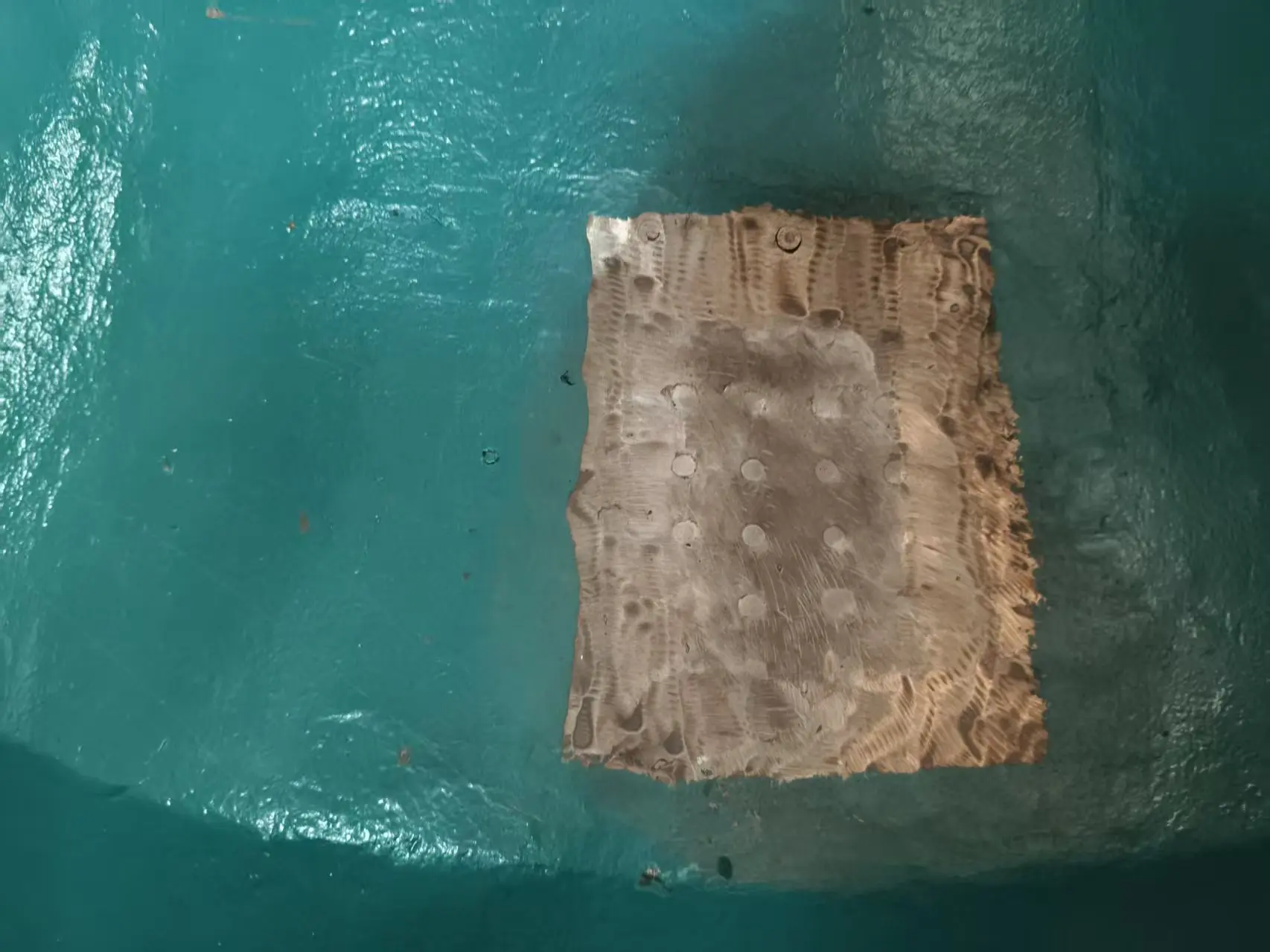

Zhixin Refractory Material Comparison Application of Titanium Carbide-based Metal Ceramic Rods on Crusher Wear Parts

Crushers are common equipment in mining, quarrying, metallurgy and other industries. They can be used to crush large pieces of iron ore, gold ore, copper ore, river pebbles, granite, basalt, limestone, quartz stone, diabase, etc. The core crusher wear parts are not only severely worn, but also have to withstand strong impact forces. They often wear out or are damaged. They need to be repaired and replaced in time, wasting a lot of manpower and material resources. So there is a titanium carbide-based metal ceramic rod applied to the wear parts of the crusher, which effectively extends the service life of the wear parts, saves costs, and improves the crushing ratio and discharge rate.

Chengdu Zhixin Refractory Technology: Innovative crusher wear parts to help enterprises reduce costs and increase efficiency

Chengdu Zhixin Refractory Technology Co., Ltd. was established in 2016 and is located in Chengdu Cross-Strait Science and Technology Industrial Park, Wenjiang District, Chengdu. The company currently has 42 products in 5 categories of wear-resistant materials, 6 core formulas of wear-resistant and heat-resistant materials, and its business covers multiple industries such as mines, quarries, cement plants, aggregate production, and energy. The company is an industry pioneer focusing on the research and development and manufacturing of wear-resistant materials. With more than ten years of deep accumulation, it provides full-stack solutions for the global crushing industry.

The relationship between cone crusher lining and cone crusher capacity

Cone crusher is a commonly used crushing equipment for medium-hard and above materials in mining crushing equipment and is widely used. There are four main factors affecting the capacity of cone crusher

Common Faults and Maintenance Points of Cone Crusher - How to select Wear-resistant Liner

As the core crushing equipment in the mining, building materials and other industries, the operating stability of the cone crusher directly affects the production efficiency. However, in long-term high-load operation, various faults are inevitable in the equipment. This article will analyze the common faults and maintenance precautions of the cone crusher, and introduce the professional solutions of Chengdu Zhixin Refractory Technology Co., Ltd. in the field of wear-resistant liner.