Importance of choosing the right cone crusher lining

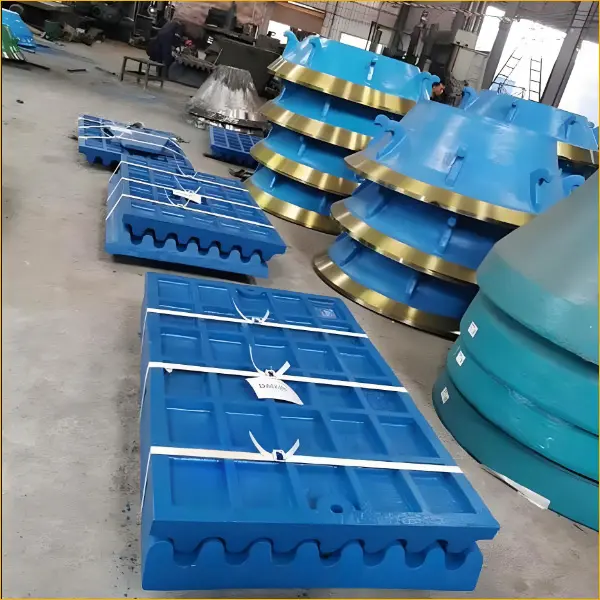

In the crushing industry, such as quarrying, aggregate production, cement production, mining, etc., cone crusher is one of the core equipment for crushing hard rock, ore and construction aggregate, and is often used for secondary crushing. Wear-resistant cone crusher lining, as its key vulnerable parts, directly affects crushing efficiency, operating costs and equipment life. Choosing the right cone Crusher Liner is particularly important because it not only improves productivity but also reduces downtime and maintenance costs.

1.The impact of lining on crushing efficiency

The lining of the cone crusher includes concave and mantle. The lining determines the shape of the crushing cavity and the crushing path of the material. If the cone crusher lining is improperly designed, it may lead to:

- Decreased crushing ratio: the material cannot be effectively squeezed and crushed, resulting in poor finished product shape, over-crushing or increased return material.

- Increased energy consumption: mismatched lining will increase the motor load and increase power consumption.

- Reduced output: unreasonable crushing cavity shape will lead to reduced throughput and affect overall production efficiency.

For example, in aggregate production, the coarse crushing liner is suitable for primary crushing of bulk materials, while the fine crushing liner is suitable for fine shaping of materials. Correct selection of liner can optimize the crushing process, improve crushing output and the quality of finished materials.

2.Liner material determines wear resistance and service life

The material of the wear liner directly affects its wear resistance and impact resistance. Common materials include:

- High manganese steel Mn13, Mn18Cr2: suitable for high impact conditions, such as granite and basalt crushing, can harden under impact to improve wear resistance.

- High chromium cast iron Cr20, Cr26: better wear resistance, suitable for high wear but low impact conditions, such as iron ore and quartz sand crushing.

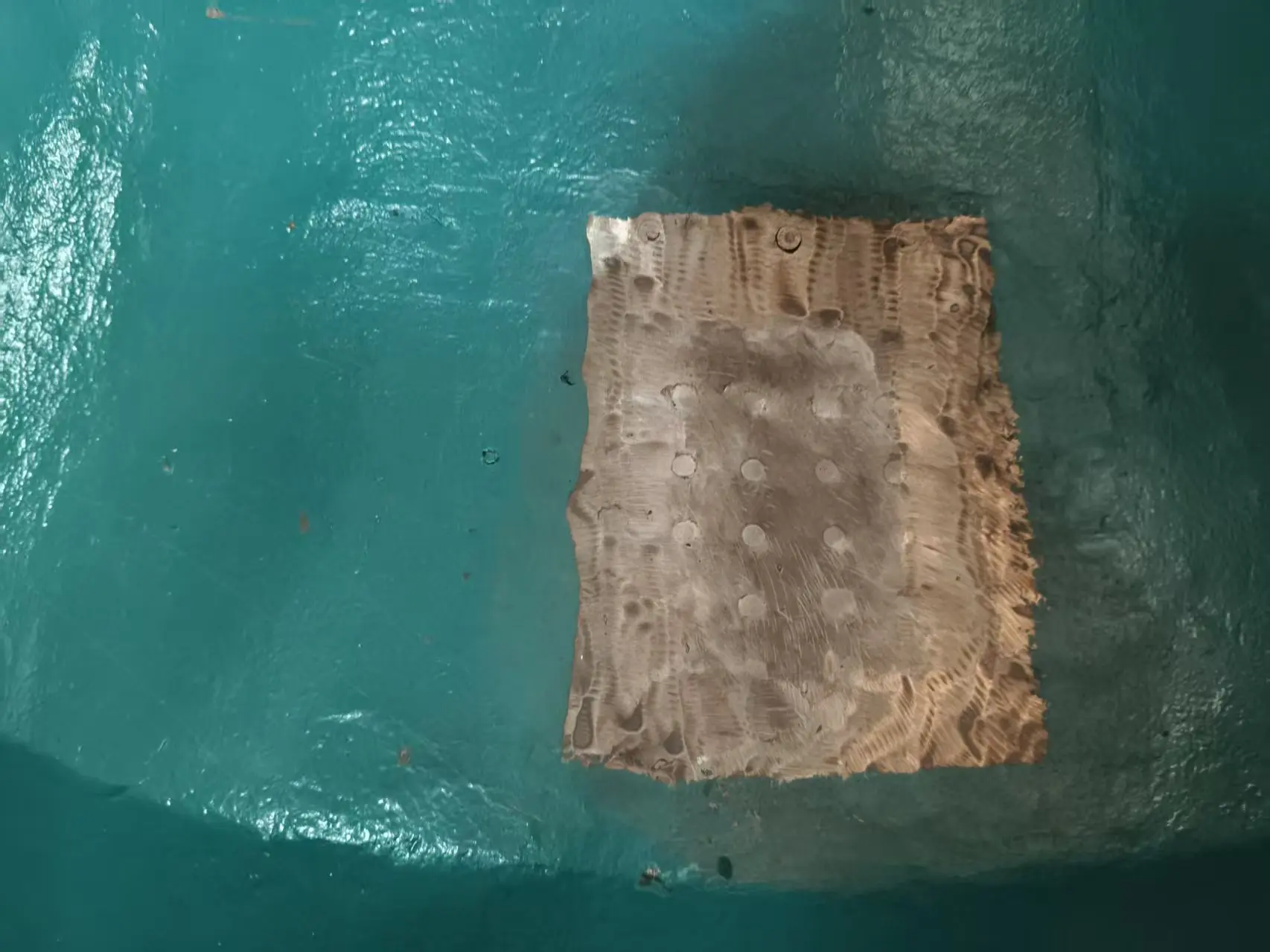

- Composite liner TIC inlay or bimetallic composite: combined with high toughness and high wear resistance, suitable for extreme wear environments.

- High manganese steel plus compound developed by Zhixin Refractory: The developed high crystal compound nails are perfectly melted into high manganese steel castings, making the wear-resistant parts both hard and tough, and the service life is 2-3 times that of conventional wear-resistant parts.

If the material is selected incorrectly, the cone crusher liner may wear, crack or even fall off quickly, which not only increases the replacement frequency, but also may damage the main components of the crusher, such as the main shaft and bearings.

3.Liner matching equipment model and working conditions

Cone crushers of different brands and models (such as Metso HP series, Sandvik CH series, Symons type) have strict requirements on the size and installation method of the liner. If an unsuitable liner is used, it may cause installation difficulties, loose liner fixation, and deformation of the crushing chamber.

In addition, the operating conditions (such as material hardness, humidity, and mud content) will also affect the selection of the liner. For example, sticky materials can easily cause the liner to adhere, and a self-cleaning liner with special surface treatment needs to be selected.

4.Economic considerations: reduce overall operating costs

Although the initial cost of high-quality liners is higher, their longer service life and more stable performance can significantly reduce the frequency of replacement, reduce downtime for replacement, and reduce maintenance costs. For example, the high-performance crusher wear parts produced by our company, although our product unit price is slightly higher than many wear parts on the market, but our products have a longer service life. Crushing the same volume of materials only requires one set of our wear parts, while other wear parts may require two, three or even several sets to achieve.

In summary, choosing the right crusher liner is very important, and it is related to many aspects. If you are not satisfied with the service life or replacement frequency of the crusher, you are welcome to consult our high-performance wear parts, which will definitely surprise you.

Contact number: 0086 18602878297 (WhatsApp) Email: zxnc01@zxnckj.com