Importance of wear parts and significance of replacement

Replacing the wear parts (jaw crusher jaw plate) of the jaw crusher is the key to ensure the continuous and efficient operation of the equipment. In the jaw crusher, the liner, thrust plate, eccentric shaft and other parts need to be replaced regularly due to long-term wear. Mastering the replacement points of these wear parts is crucial to extending the overall life of the equipment. Next, we will explore the key points in the replacement process of these wear parts.

Reference to the approximate replacement cycle of the main Jaw Crusher Wear Parts:

Reference for the approximate replacement cycle of main wear-resistant parts:

(For reference only, because the service life varies depending on the crushed materials (including dryness and wetness) and working conditions.)

| Name of Wear -- Prone Parts | Material | General Service- Life (Months)

| Minimum Stock- Quantity

|

| Movable Jaw Liner | High Manganese-Steel | 4 | 2 sets |

| Fixed Jaw Liner | High Manganese-Steel | 4 | 2 sets |

| Bracket | Cast Iron | 2 | 2 sets |

| Main Bearing- Bushing | Poured Babbitt-Metal | 24 | 1 set |

| Eccentric Shaft- Bearing Bushing | Poured Babbitt-Metal | 36 | 1 set |

| Movable Jaw- Spindle Bearing- Bushing | Bronze |

12 |

1 set |

In the jaw crusher, the Fixed Jaw Plate, the movable jaw plate and the lining plates (guard plates) on both sides are extremely easy to wear out. Once these lining plates are severely worn, the product particle size will increase directly, affecting the crushing effect. When the lining plate is initially worn, we can take some temporary measures, such as turning the lining plate over, or exchanging the upper and lower lining plates to reduce wear. However, when the jaw plate wear reaches 60% or the lining plates on both sides are worn off by 40%, new lining plates must be replaced in time to ensure the continuous and efficient operation of the crusher.

If the jaw crusher frequently replaces the wear-resistant jaw plate, the crusher will often stop, which not only affects the production capacity, but also brings pressure to the equipment maintenance team. In addition, the replacement time and replacement cost increase, and the transportation cost also increases accordingly.

So how to optimize this problem? The answer is simple, that is, to choose a wear-resistant part of the crusher with a longer service life.

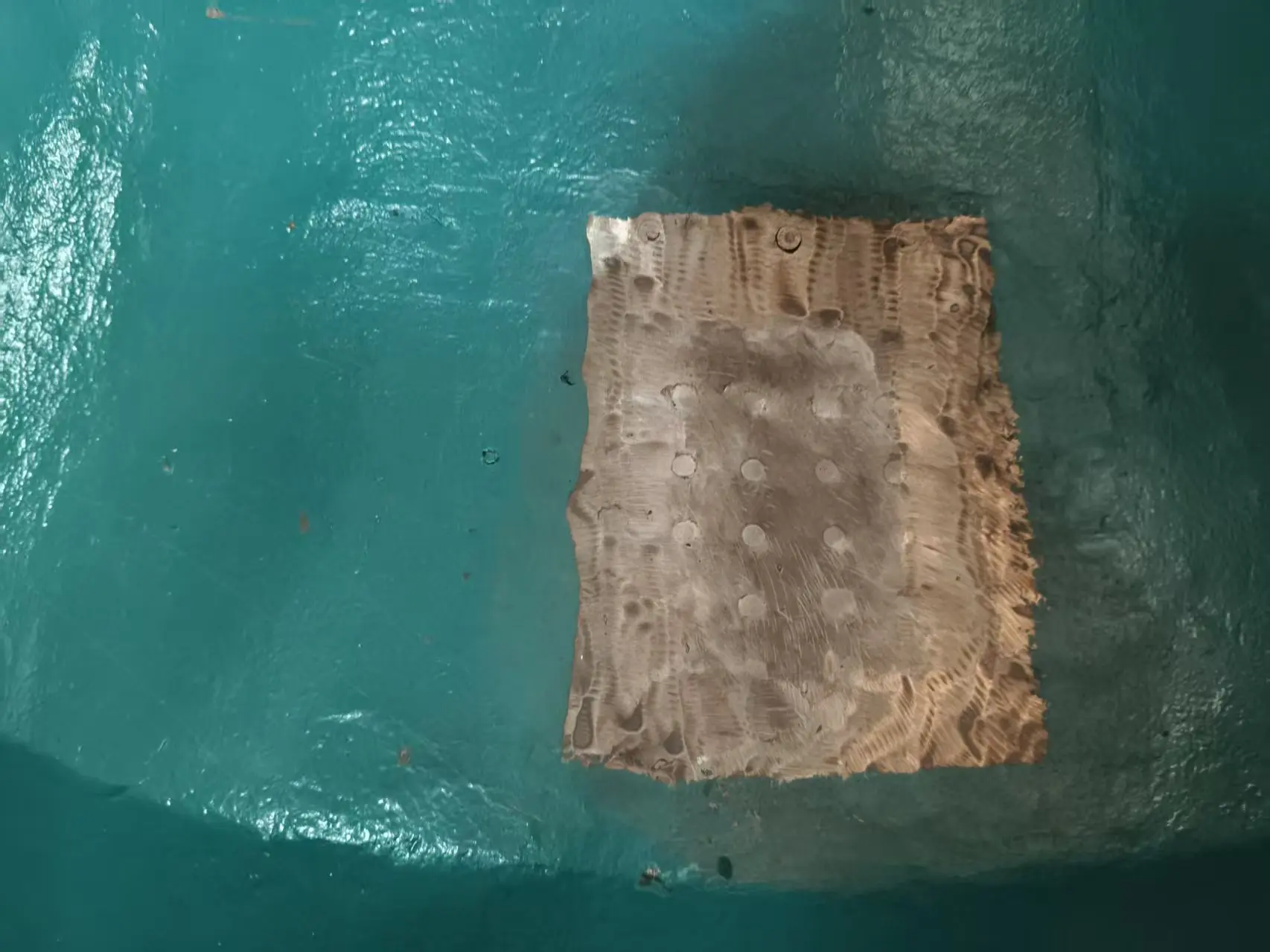

Chengdu Zhixin Refractory Technology has developed high-crystalline nano-compound wear-resistant parts to solve this pain point that is common in the crushing industry. Under the same working conditions, the service life of our wear-resistant parts is 2-3 times that of ordinary wear-resistant parts. For example, if the user's original jaw plate can be used for 60 days, our super wear-resistant jaw plate can be used for more than 120 days. This greatly reduces the user's replacement frequency and reduces the user's comprehensive use cost.

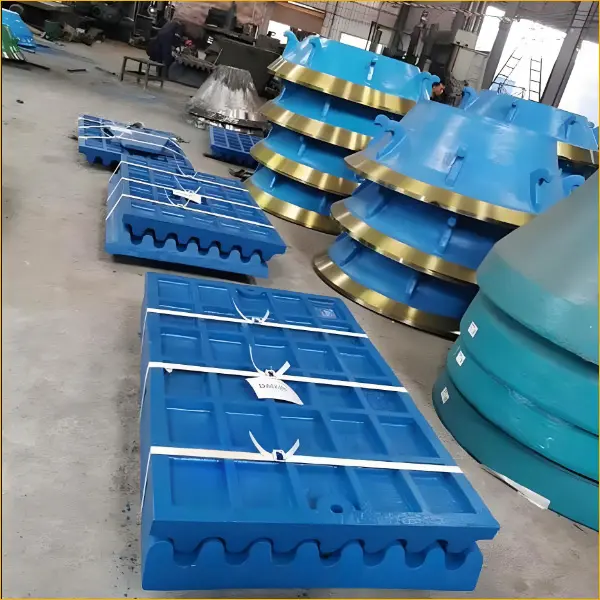

In addition to the jaw crusher jaw plate, Zhixin also provides cone crusher liners (Concave and mantle), ball mill liners, hammer heads, composite wear-resistant plates, etc. for the majority of users.

If you are interested in wear-resistant parts with longer service life, you are welcome to come to consult and learn more about the details of our high-crystalline nano-compound wear-resistant parts.

Contact number/WhatsApp: 008618602878297 Email: zxnc01@zxnckj.com