Improve crushing efficiency and extend service life - Chengdu Zhixin Refractory Technology creates high-quality cone crusher linings for you.

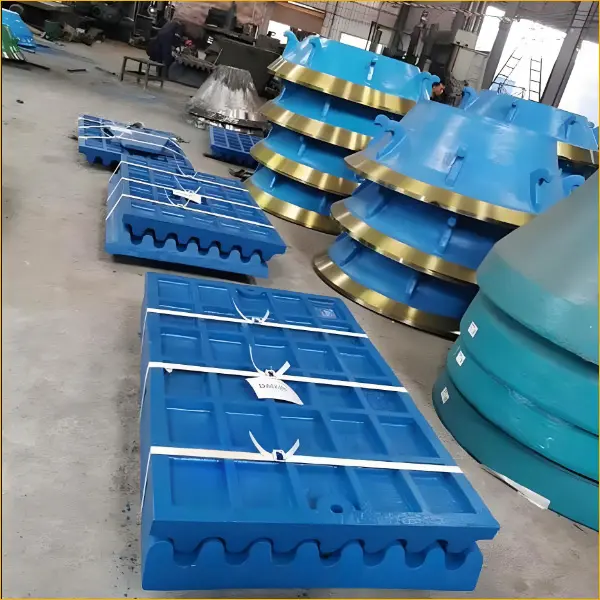

In mining, building materials, metallurgy and other industries, cone crushers are one of the core crushing equipment, and their working efficiency and stability directly affect the operating cost and production capacity of the production line. As a key wear-resistant component of the crusher, the service life and performance of the liner are crucial. Chengdu Zhixin Refractory Technology Co., Ltd. focuses on the research and development and production of high-wear-resistant crusher accessories. With advanced material technology and mature process experience, it provides the industry with high-performance cone Crusher Liners. This article explains the technical essentials of filling liner fillers for cone crushers.

The importance of cone crusher liner fillers.

When the cone crusher crushes high-hardness ores (such as granite, basalt, iron ore, etc.), the moving cone and the fixed cone liner are subjected to huge impact force and friction wear. If the filling material between the liner and the body is not good enough, the liner will loosen, shift, and even cause equipment damage, seriously affecting production safety and efficiency. Therefore, high-quality liner fillers can not only fix the liner, but also effectively buffer the impact force, reduce metal fatigue, and extend the service life of the liner.

Common filler material types.

1. Epoxy resin filler

- Advantages: high strength, corrosion resistance, no shrinkage after curing

- Disadvantages: high cost, strict construction process requirements

- Applicable occasions: large cone crushers, high load conditions

2. Zinc alloy filler

- Advantages: good fluidity, dense filling, excellent thermal conductivity

- Disadvantages: high melting point, professional heating equipment is required during construction

- Applicable occasions: small and medium-sized cone crushers, high temperature rise conditions

3. Polyurethane filler

- Advantages: good elasticity, significant shock absorption effect, simple construction

- Disadvantages: limited high temperature resistance

- Applicable occasions: crushing environment with large vibration

4. Cement-based filler

- Advantages: low cost, easy to obtain materials

- Disadvantages: long curing time, slow strength development

- Applicable occasions: temporary maintenance or low load conditions

Key points of filling construction process.

1. Preparation before construction

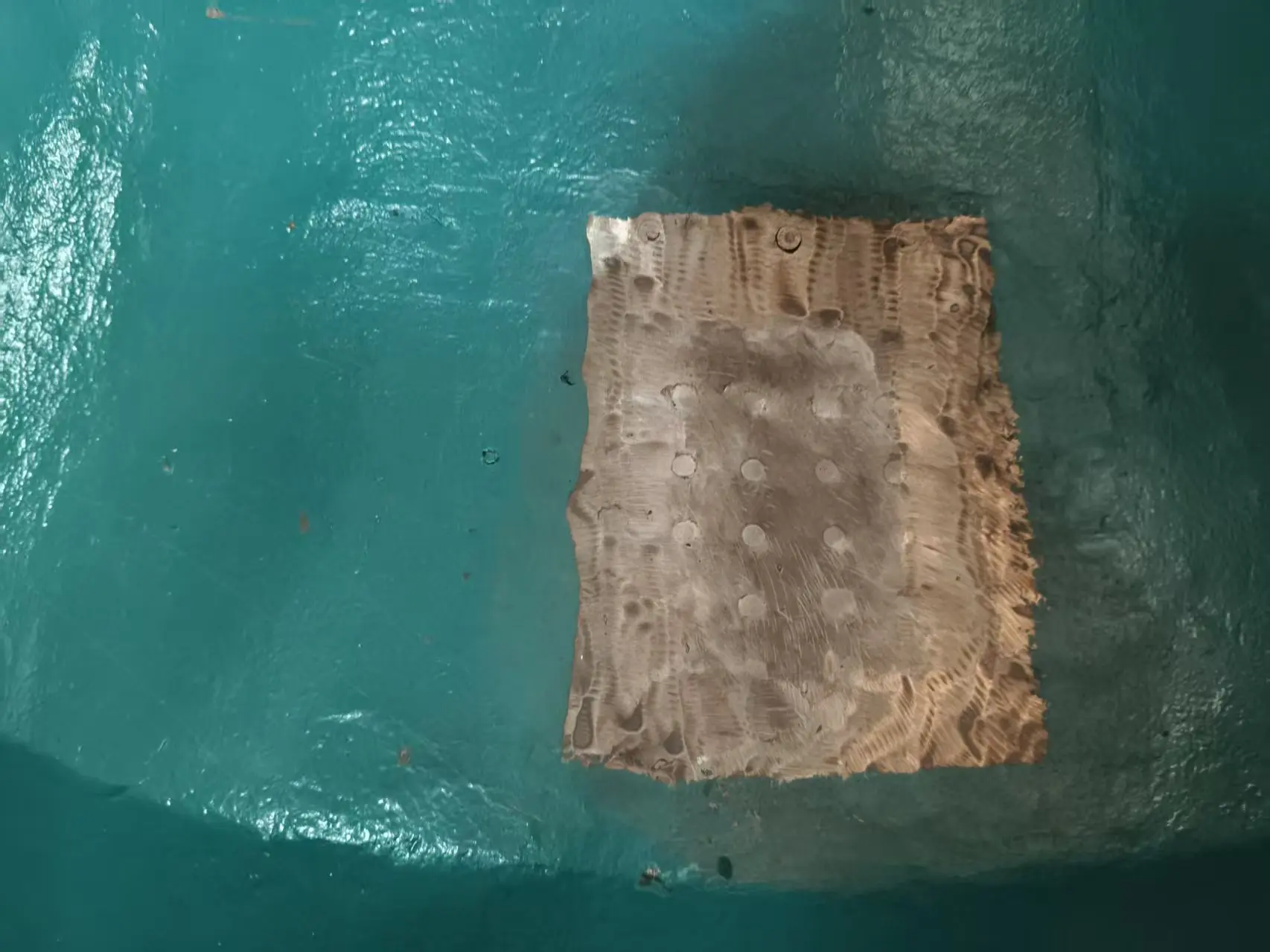

- Thoroughly clean the contact surface between the liner and the main machine to remove oil, rust and old filler residues

- Check whether the liner locating pins and bolt holes are intact

- Prepare necessary molds and baffles to prevent packing leakage

2. Mixing and pouring of packing

- Strictly mix according to the ratio provided by the material supplier

- Use a pouring sequence from bottom to top to avoid bubbles

- Control the pouring speed to ensure that the packing can fully fill all gaps

3. Curing process control

- Keep the ambient temperature within the range required by the material

- Avoid moving or vibrating the equipment during curing

- Determine a reasonable curing time based on the material properties

4. Post-processing

- Remove excess packing material

- Check the filling density and refill if necessary

- Perform necessary dimensional inspections and corrections

Chengdu Zhixin Refractory Technology Co., Ltd. has many years of experience in the research and development of wear-resistant materials. Its products have passed ISO 9001 quality management system certification and are widely used in large-scale mines and building materials companies at home and abroad. We not only provide high-quality products, but also customize exclusive solutions according to customer needs to ensure maximum equipment operation efficiency.