Innovator of wear-resistant technology: How Chengdu Zhixin Refractory Technology reshapes the performance of crusher linings

In industries such as mining, cement and building materials, crushers, as core equipment, undertake heavy material crushing tasks. As a component that directly contacts the material, the wear resistance of the crusher lining directly affects the working efficiency and production cost of the equipment. Chengdu Zhixin Refractory Technology Co., Ltd., with its excellent wear-resistant material research and development capabilities, produces compound crusher wear-resistant parts with a service life of more than twice that of conventional products under the same working conditions, bringing revolutionary changes to the industry.

Types and functions of crusher linings

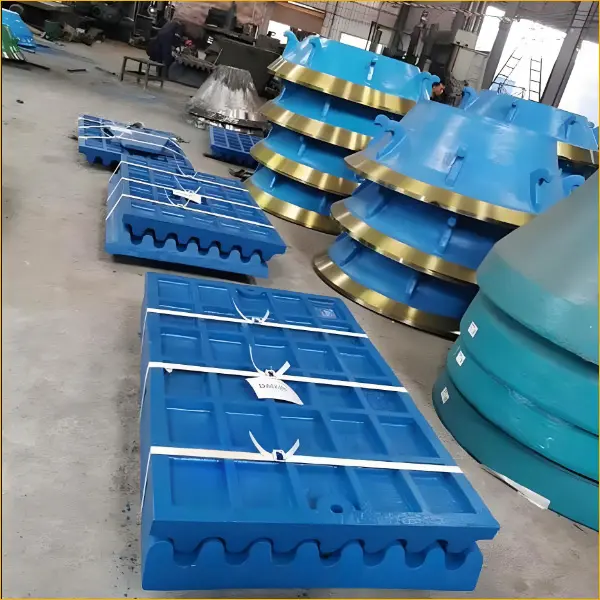

Crusher linings can be divided into many types according to the type and working principle of the crusher. The jaw crusher lining mainly includes a fixed jaw plate and a movable jaw plate, which cooperate with each other to form a crushing chamber; the Cone Crusher lining is divided into a movable cone lining and a fixed cone lining; the impact crusher lining mainly includes an impact plate and a plate hammer; and the hammer crusher uses the hammer head as the main wear-resistant component.

The core functions of these liners include: protecting the main structure of the crusher from wear, forming a suitable crushing cavity to improve crushing efficiency, and avoiding damage to key equipment components through self-wear. Under harsh working conditions, high-quality liners can significantly reduce the frequency of shutdown and replacement, and improve overall production efficiency.

Limitations of traditional liner materials

For a long time, high manganese steel has been the main material for Crusher Liners. This material has good work hardening properties under strong impact conditions, but performs poorly under medium and low impact conditions. In addition, although traditional high-chromium cast iron has high hardness, it lacks toughness and is prone to brittle fracture. In practical applications, these materials often face the problems of fast wear and frequent replacement, resulting in high production costs.

Innovative breakthroughs of Chengdu Zhixin Refractory Technology

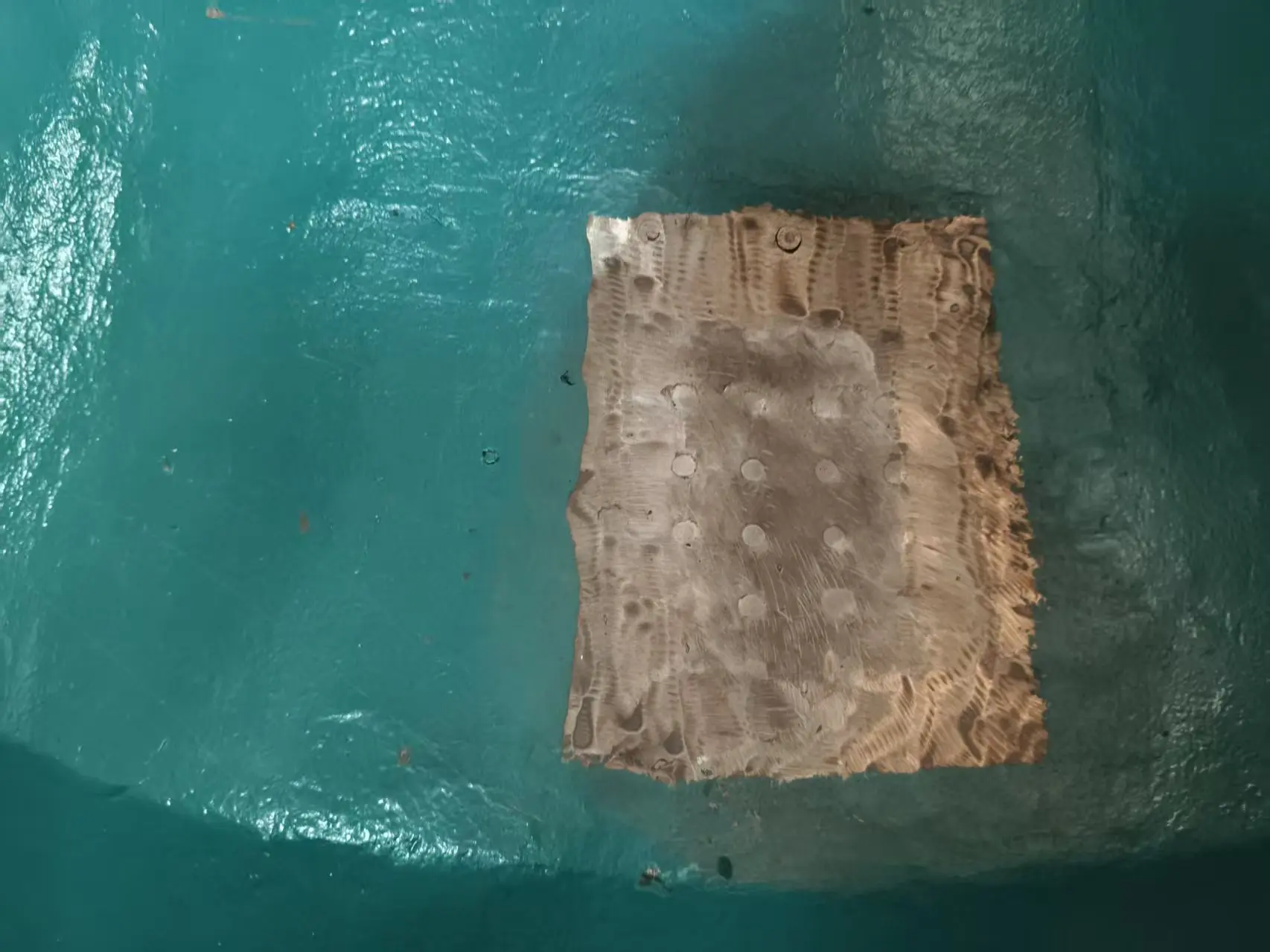

In response to these industry pain points, Chengdu Zhixin Refractory Technology Co., Ltd. has developed composite wear-resistant material technology with independent intellectual property rights. Through microstructure regulation and multi-element alloying design, the company has successfully developed a new material that maintains high hardness and good toughness. Its core technology lies in the precise control of carbide morphology and distribution, as well as the optimization of matrix structure, so that the material can show excellent wear resistance under different impact conditions.

It is particularly worth mentioning that the gradient wear-resistant materials developed by the company use differentiated material ratios in different parts of the liner. Ultra-high hardness materials are used in high-wear areas, while high-toughness materials are used in supporting parts. This design concept greatly improves the overall service life of the liner.

Actual application effect and industry value

In actual applications, Chengdu Zhixin's product performance is remarkable. In a comparative test of a large iron ore, the average service life of the jaw crusher using traditional high-manganese steel liners was 45 days, while the service life of the Zhixin Refractory Technology products reached more than 110 days. Similar effects also appeared in limestone crushing in the cement industry, and the liner replacement cycle was extended from the original 60 days to 140 days.

The economic benefits brought by this performance improvement are very significant. Taking a medium-sized stone crushing plant as an example, the number of liner replacements can be reduced by 6-8 times per year, saving direct material costs and downtime losses of more than US$70,000. From a more macro perspective, the increased life of wear-resistant parts also reduces scrap steel generation and energy consumption, which has obvious environmental benefits.