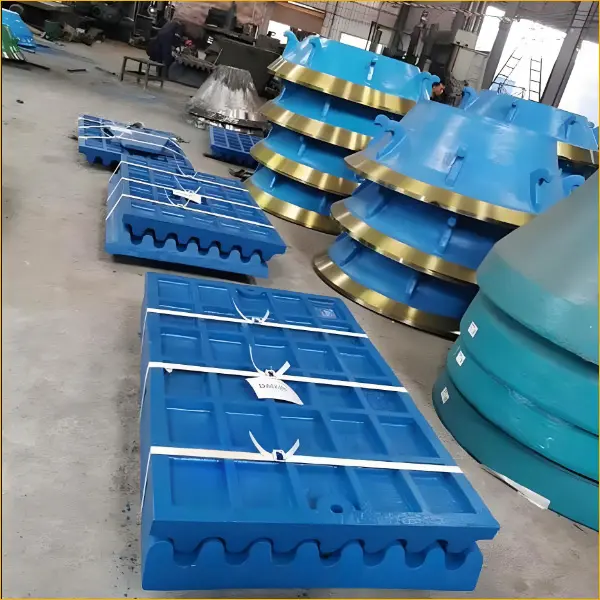

Super wear-resistant jaw crusher jaw plate: a wise choice to improve crushing efficiency and reduce operating costs

In mining, building materials, metallurgy, glass, stone and other industries, jaw crusher is the core equipment for primary crushing, and its performance directly affects production efficiency and operating costs. The core wear-resistant component of the jaw crusher, the jaw plate, is the key factor in determining the life of the equipment and the crushing effect. Chengdu Zhixin Refractory Technology Co., Ltd., relying on advanced casting technology and material research and development capabilities, has launched super wear-resistant Jaw Crusher Jaw Plates, whose service life can reach 2-3 times that of conventional products, greatly improving crushing efficiency, reducing the frequency of downtime and replacement, while saving customers transportation costs and tariffs, etc., creating higher economic benefits for customers.

Working principle of jaw crusher and the importance of jaw plates

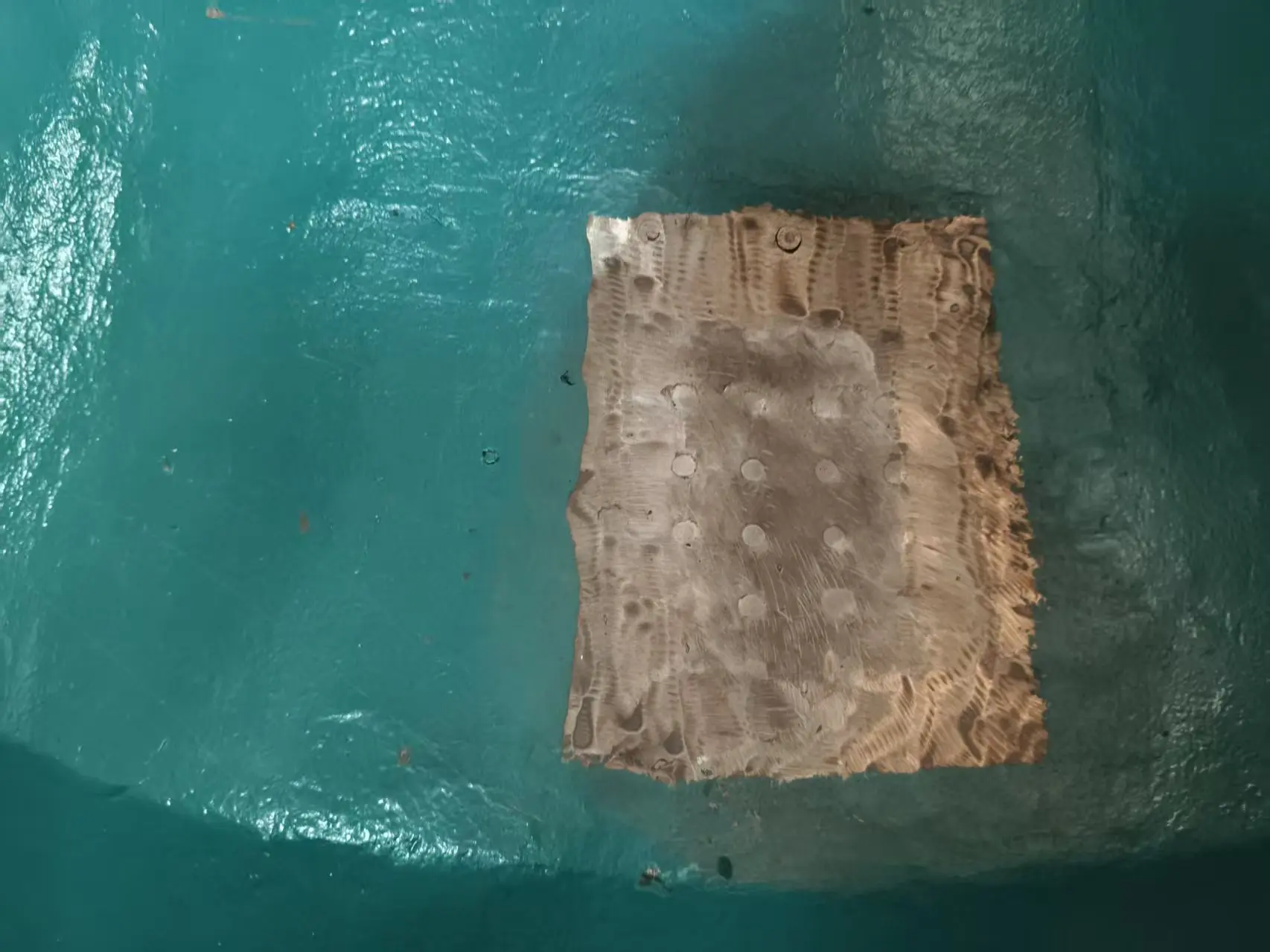

The jaw crusher crushes large pieces of ore or rock into the required particle size through the periodic extrusion movement of the movable jaw and the Fixed Jaw. In this process, the jaw plate is in direct contact with the material and bears huge impact and friction. Due to material and process limitations, ordinary jaw plates are prone to wear, deformation and even breakage, resulting in reduced crushing efficiency, increased energy consumption, and frequent replacement, affecting production continuity.

Advantages of Zhixin Super Wear-resistant jaw plate

Chengdu Zhixin Refractory Technology uses high manganese steel plus special wear-resistant compounds, combined with advanced casting technology, to give the jaw plate the following core advantages:

1. Super long service life

- Using high hardness and high toughness compound materials, tensile strength of 1500MPa, hardness HRC65-68 degrees, wear resistance far exceeds ordinary high manganese steel jaw plate, service life increased by 2-3 times, reduce replacement frequency, and reduce spare parts costs.

2. Improve crushing efficiency

- The optimized tooth shape design combined with high wear-resistant materials ensures that the crushing chamber maintains the best bite state for a long time, avoids uneven particle size caused by wear, and improves the quality of finished products.

3. Reduce comprehensive operating costs

- Reduce downtime and replacement time, and improve equipment utilization.

- Reduce maintenance and labor costs, and extend the overall life of the equipment.

- Reduce waste generation and improve resource utilization.

4. Adapt to harsh working conditions

- Designed for high-hardness ores (such as granite, basalt, iron ore, etc.), it has strong impact resistance and avoids early failure.

5. Wide range of application scenarios

Whether it is coarse crushing in mines, construction waste treatment, or sand and gravel aggregate production, Chengdu Zhixin Refractory's super wear-resistant jaw plates can significantly improve equipment performance, especially suitable for:

**High wear conditions, such as crushing of hard materials such as quartz stone and pebbles.

**Continuous high-production demand, reduce downtime maintenance, and ensure stable production.

**The goal of reducing costs and increasing efficiency helps customers save a lot of costs in long-term operations.

In the increasingly competitive crushing industry, the efficient and stable operation of equipment directly affects the profitability of the company. Chengdu Zhixin Refractory Technology Co., Ltd.'s super wear-resistant jaw crusher jaw plates, with material innovation, process optimization and excellent performance, have become an ideal choice for customers to improve production efficiency and reduce operating costs. Choosing us means choosing a more durable and efficient crushing solution!

Contact us to get customized wear-resistant parts solutions to help your crushing business run efficiently!