Zhixin Refractory Material Comparison Application of Titanium Carbide-based Metal Ceramic Rods on Crusher Wear Parts

Crushers are common equipment in mining, quarrying, metallurgy and other industries. They can be used to crush large pieces of iron ore, gold ore, copper ore, river pebbles, granite, basalt, limestone, quartz stone, diabase, etc. The core crusher wear parts are not only severely worn, but also have to withstand strong impact forces. They often wear out or are damaged. They need to be repaired and replaced in time, wasting a lot of manpower and material resources. So there is a titanium carbide-based metal ceramic rod applied to the wear parts of the crusher, which effectively extends the service life of the wear parts, saves costs, and improves the crushing ratio and discharge rate.

Titanium carbide-based metal ceramics are a kind of hard alloy material produced by powder metallurgy with titanium carbide (TiC) as the hard element, high manganese steel and other metal powders as the bonding element, and then appropriately added with the corresponding alloy elements. It is made into a rod, which is a titanium carbide-based metal ceramic rod. When producing wear-resistant castings for crushers, molten high-manganese steel liquid is used for casting, and alloy rods are cast on the working surface of wear-resistant parts to prepare composite wear-resistant parts.

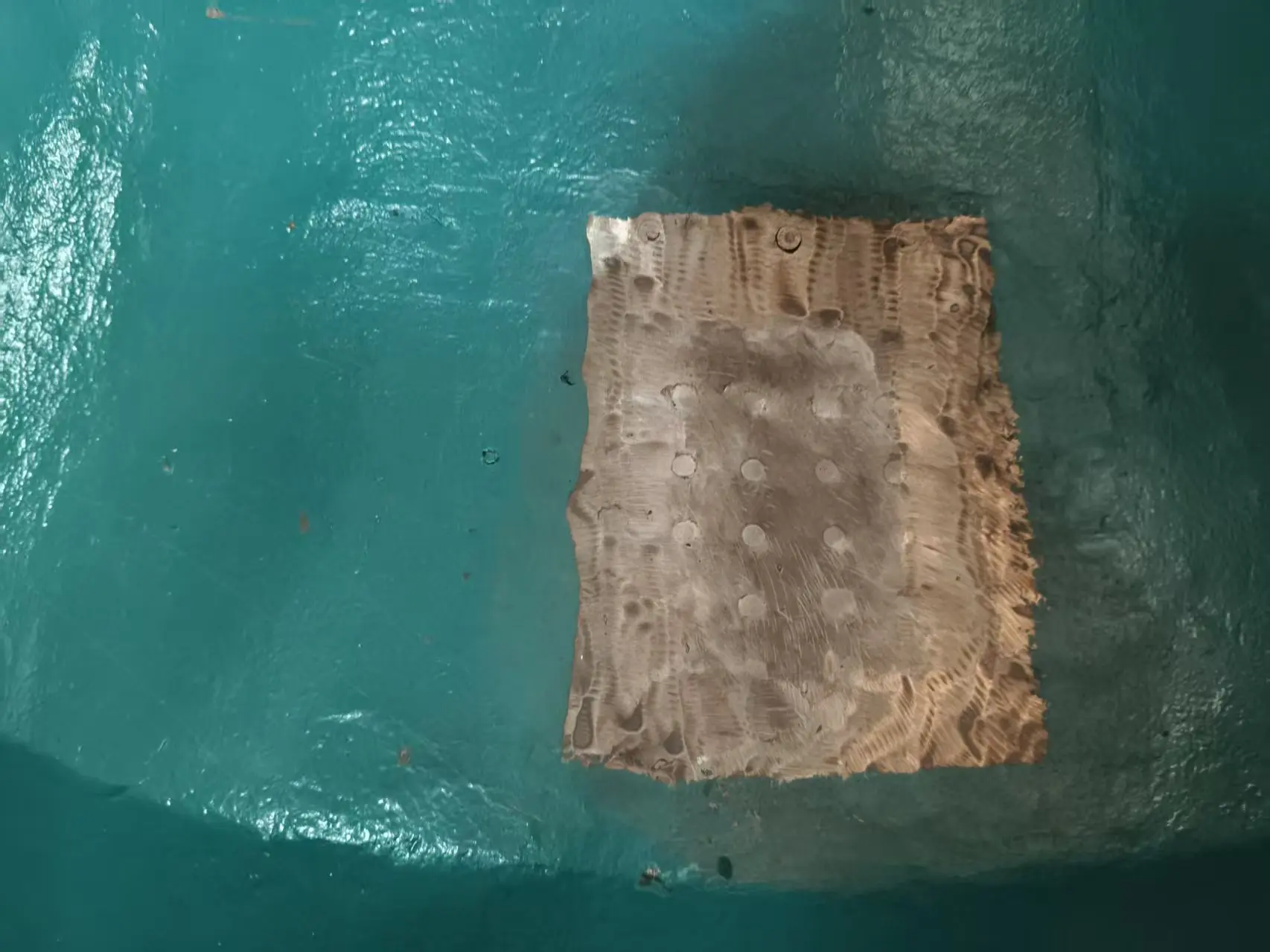

However, the casting of titanium carbide rods into wear-resistant parts of crushers also has its disadvantages, which are mainly reflected in the shrinkage rate of titanium carbide rods and high manganese steel. Different shrinkage rates cause gaps around the cast titanium carbide rods, thus affecting the product quality. Another situation is that titanium carbide rods are mostly inserted into the mold, which is easy to be washed and offset during casting, thus affecting the final quality of wear-resistant parts.

Zhixin Refractory Technology has been deeply engaged in wear-resistant parts of mining equipment for more than ten years. It is a technology company integrating research and development, production, sales and empowerment. The high-crystalline nano-compounds developed by the company are perfectly melted into the wear-resistant parts of the crusher, and better wear-resistant products are obtained than titanium carbide rods. Because our compounds are composed of more than 40 metals through 4 processes, their shrinkage rate is perfectly matched with high manganese steel, so that there will be no gaps around the compound nails of the finished product. In addition, we use a special process to firmly fix the compound nails on the mold, so that they will not be washed out and tilted during pouring. In addition, our "smart manufacturing ecological chain system" has 24-hour real-time control to ensure that every link in the casting process is accurate.

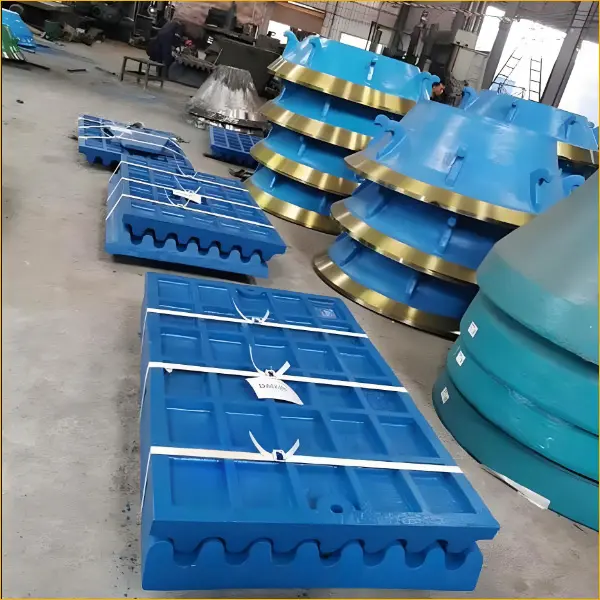

Our high-crystalline nano-compound wear-resistant parts can be used in jaw crusher jaws, cone crushing lining, mortar walls, crushing chambers, fixed cone linings, dynamic cone linings, crusher hammers, plate hammers, roller rings of roller machines, etc. We can ensure that our wear-resistant parts have a service life of 2-3 times that of conventional wear-resistant parts, greatly improving your production efficiency and saving production costs for you.

You are welcome to consult by email zxnc01@zxnckj.com or WhatsApp 008618602878297. We are always ready to provide you with a full stack of crusher wear-resistant parts services.