Products

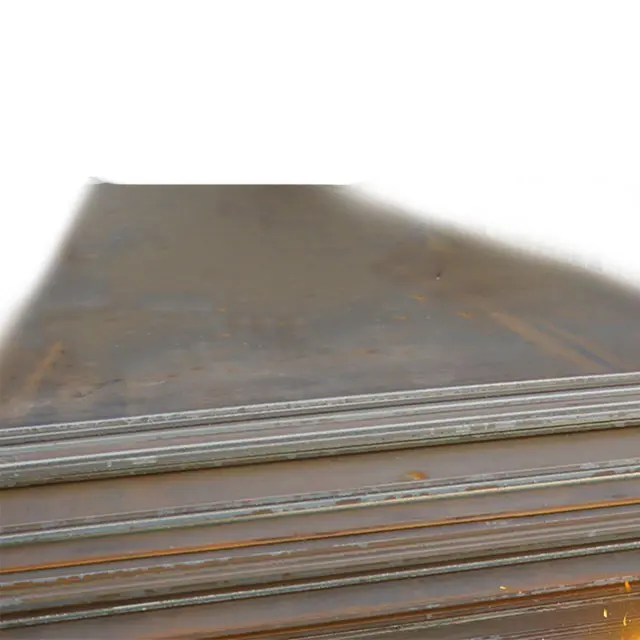

Zhixin compound super wear-...

Zhixin composite super wear-resistant plate is made of high-performance steel plate as the base material and then welded with high wear-resistant welding wire. Our composite wear-resistant plates are widely used in fan blades, mixer blades, coal mill chutes, mining transport car linings, etc., which increases the wear resistance of the equipment by 2-3 times.

In the quarry application o...

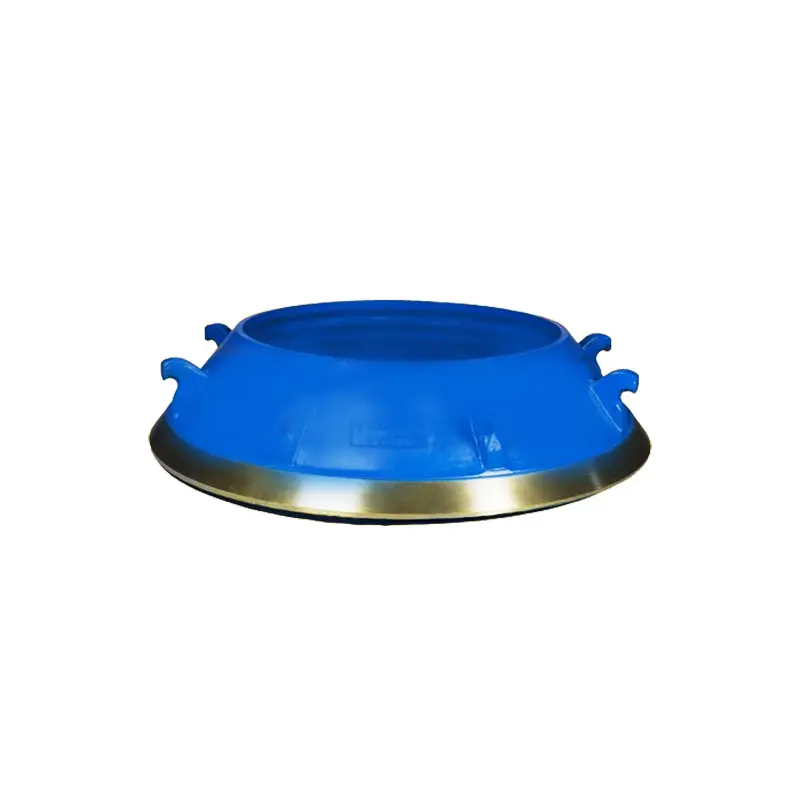

The cone crusher liner is composed of two parts, usually the outer concave liner and the inner cone mantle (concave and mantle). The concave rotates elliptically under the drive of the eccentric shaft, thereby impacting and squeezing the rocks or other materials between the crushing cavities, so that the materials are crushed from large to small and then discharged from the gap at the bottom of the cone crusher liner. The concave and mantle are the core wear parts of the cone crusher, and are also vulnerable parts that need to be replaced regularly. Chengdu Zhixin Refractory Technology is committed to providing professional wear-resistant parts services for crushers, saving users' worries and costs with wear-resistant parts with longer service life.

High manganese steel cone c...

Our crusher wear parts are added with high-crystalline nano compounds developed by us. According to the main wear areas of the cone crusher linings reported by customers, we customize the addition of compound nails, making the service life of the crusher wear parts 2-3 times that of ordinary wear parts.

Cone crusher mantle and con...

The cone crusher mantle and concave are the key component in the cone crusher that directly contacts the material, so, it's very important to choose high-performance cone crusher wear parts.

Bowl liner of cone crusher ...

The mantle and concave of cone crusher are generally made by Manganese steel. Its firmness should be checked after the cone crusher has been running for a period of time. The concave and mantle cooperate with each other and rotate in an elliptical trajectory to crush ore or other materials.

Manufacturer of cone crushe...

The wear-resistant parts of cone crusher mainly refer to the concave and mantle, which play a vital role in crushing. The service life of the cone crusher liners is related to the downtime replacement time, thus affecting the crushing output.

Manganese steel concave and...

During the working process of crushing, the motor drives the eccentric sleeve to rotate through the transmission device, and the moving cone liner (mantle) rotates and swings under the force of the eccentric sleeve. The section where the moving cone liner is close to the fixed cone liner (concave) becomes the crushing chamber, and the material is crushed by multiple squeezing and impact of the mantle and concave. When the mantle leaves this section, the material that has been crushed to the required particle size falls under its own gravity and is discharged from the bottom of the cone liners. The material to be crushed is loaded from the feed port of the cone crusher.

Factory Direct Sale New Min...

The jaw plate, also known as the tooth plate or pressure plate, is the main working part of the jaw crusher. The material is crushed by the extrusion and splitting action between the movable jaw plate and the fixed jaw plate. Wear is mainly caused by sliding friction and repeated extrusion of the material, which manifests as surface cutting, crack expansion or material shedding. In order to increase the service life, it is critical to choose a high-performance jaw plate.

Wholesale Mining Machinery ...

Zhixin is a professional manufacturer of crusher parts. Servicing the mining and construction industries for years, we have built up a scientific system of production, sales and services. We are offering products over 20 countries and enjoy good reputation among our customers for high-quality products, integrity and responsibility.Our products range from cone crushers liners and jaw crusher jaw plates to customied casting parts.

Our goal is to provide overall cost-saving products and improve the productivity of equipment.

Casting Factory Ore Crushin...

Jaw crusher is a common coarse crushing equipment in sand and gravel production lines. It's core components are the two jaws, fixed jaw and movable jaw. Chengdu Zhixin Refractory Technology is manufacturer of crusher wear parts, including jaw plates, liners, compound steel plates.

Factory Wholesale Energy & ...

The jaw plate of jaw crusher is divided into fixed jaw plate and movable jaw plate, generally both of them are high-manganese steel castings. When working, the movable jaw is attached to the movable jaw plate to make a compound swing motion, forming an angle with the fixed jaw plate to squeeze the stone. Therefore, the jaw plate of jaw crusher is easy to wear and needs to be replaced within a certain period of time. In order to extend its service life, its shape is generally designed to be symmetrical up and down, that is, it can be turned around when one end is worn. The movable jaw plate and the fixed jaw plate are the main contact surfaces when crushing stones. The movable jaw plate is installed on the movable jaw to protect the movable jaw.

Factory Price Casting High ...

The jaw plate is one of the core components of the jaw crusher, including the movable jaw plate and the fixed jaw plate. When working, the jaw peaks of the movable jaw and the fixed jaw should face the jaw valleys. In this way, in addition to the squeezing effect on the material, there is also a bending effect during crushing, making it easier to crush the material.

The material of the jaw plate is usually manganese steel containing more than 13% manganese, and ZGMn13 and ZGMn18 are commonly used. Our high-performance jaw plates are added with specially developed alloys to further improve the wear resistance of the jaw plates and extend their service life.