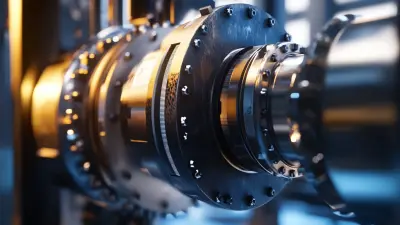

Simons Cone Crusher Parts: OEM Manufacturers & Exporters for Quality Replacement Solutions

Enhance your crushing operations with premium Simons Cone Crusher Parts from Chengdu Zhixin Refractory Technology Co., Ltd. Our wide selection of replacement parts is engineered for optimal performance and durability in Simons Cone Crushers. Manufactured from high-quality materials, these components comply with industry standards, ensuring reliability and efficiency in demanding environments. Whether you require wear parts, linings, or specialized components, our solutions integrate seamlessly into your existing machinery, reducing downtime and increasing productivity. Committed to excellence and customer satisfaction, Chengdu Zhixin Refractory Technology Co., Ltd. is a trusted partner in the mining and aggregate sectors. Choose our Simons Cone Crusher Parts for enhanced crushing performance and lower maintenance costs. Rely on us for tailored innovative solutions that keep your equipment operating smoothly and effectively, prioritizing quality and reliability for all your crusher parts needs.

Tips & Tricks for Simons Cone Crusher Parts Stands Out Application

When it comes to maximizing the performance and lifespan of your Simons cone crusher, understanding the role of quality parts is paramount. At Chengdu Zhixin Refractory Technology Co., Ltd., we specialize in producing high-manganese steel components designed to withstand extreme wear and high-temperatures, ensuring that your crushing operations remain efficient and productive. Our extensive research into the properties of wear-resistant materials allows us to offer parts that not only fit perfectly but also enhance the longevity of your equipment. Investing in superior Simons cone crusher parts leads to better operational performance. Regularly maintaining and upgrading your parts with materials that resist wear and tear can significantly reduce downtime and maintenance costs. Our team recommends monitoring key components for signs of wear, and when replacements are necessary, opting for our high-quality, specially engineered parts that meet stringent industry standards. With over a decade of expertise in manufacturing and research, we provide solutions that stand out in the market, ensuring you get the most value for your investment. In addition, effective application of these parts depends on not only the quality but also proper installation and maintenance practices. Collaborating with our experts can help you determine the best practices tailored to your specific requirements. As a global supplier, Chengdu Zhixin Refractory Technology is committed to delivering excellence, assisting you in achieving higher productivity, and ensuring the reliability of your Simons cone crusher throughout its operational life. Choose quality; choose us.

Tips & Tricks for Simons Cone Crusher Parts Stands Out Application

| Part Name | Material | Application Area | Maintenance Tips | Expected Lifespan |

|---|---|---|---|---|

| Mantle | High Manganese Steel | Crushing Hard Materials | Check for wear regularly; replace if worn. | 300-500 hours |

| Concave | High Manganese Steel | Primary & Secondary Crushing | Inspect regularly and adjust for optimal performance. | 250-450 hours |

| Bowl Liner | Alloy Steel | Crushing All Material Types | Monitor for wear patterns; replace when necessary. | 300-600 hours |

| Drive Shaft | Carbon Steel | Power Transmission | Ensure lubrication is adequate; check for wear. | 500-1000 hours |

| Hydraulic Cylinder | Aluminum Alloy | Clamping and Adjustment | Regularly check seals and fluid levels. | 350-700 hours |

Best Strategies For Simons Cone Crusher Parts Leads the Global Market Global Reach

O

Oliver Collins

I am very impressed! The quality is unmatched and the customer care team was very informative.

21 May 2025

A

Anthony Diaz

Excellent product and service! The representatives were remarkable in their professionalism.

09 May 2025

J

James Torres

Exceptional product quality and a very professional customer service team to back it up!

29 June 2025

E

Eva Sanchez

The product is of great quality! The customer service team was very knowledgeable.

28 June 2025

J

Julia Morgan

The quality is outstanding! I was particularly impressed with the efficient after-sales service.

07 July 2025

M

Madison Martinez

Fantastic product! I appreciated the thorough follow-up from the support team.

21 June 2025