Wholesale Symons Cone Crusher Head Ball - Top Manufacturers & Reliable Suppliers

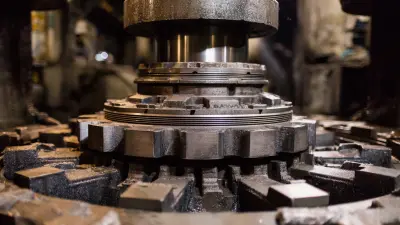

The Symons Cone Crusher Head Ball is a crucial component for optimizing the performance of cone crushers. Manufactured by Chengdu Zhixin Refractory Technology Co., Ltd., this part is designed for durability and reliability, even in the most demanding conditions. Constructed from high-quality materials, the head ball is resistant to wear and impact, ensuring an extended service life and lower maintenance costs. It plays a pivotal role in the crushing process by delivering optimal crushing action, resulting in increased productivity. With a commitment to precision and rigorous testing to meet industry standards, Chengdu Zhixin Refractory Technology Co., Ltd. combines innovative technology with extensive experience to provide exceptional solutions for the mining and construction industries. Choosing our Symons Cone Crusher Head Ball guarantees superior performance and compatibility with various Symons models, enhancing operational efficiency.10 Essential Tips For Symons Cone Crusher Head Ball in 2025 Where Service Meets Innovation

As we look ahead to 2025, the importance of innovative solutions in the mining and construction industries has never been more evident, especially concerning the performance and maintenance of Symons cone crushers. Chengdu Zhixin Refractory Technology Co., Ltd., founded in 2010, is at the forefront of this evolution, specializing in high-temperature resistant materials and wear-resistant technologies that extend the lifecycle of critical components, such as the head ball of Symons cone crushers. Here are ten essential tips that can guide global buyers in maximizing the efficiency and lifespan of their equipment. First, understanding the material composition is crucial. Opting for high manganese steel ensures that the head ball can withstand severe impact and abrasion, thus reducing the need for frequent replacements. Next, regular inspections and maintenance are vital. Implementing a rigorous maintenance schedule can help identify wear patterns early, allowing for timely replacements and preventing unexpected downtimes. Additionally, investing in quality aftermarket parts from reputable suppliers like Zhixin can significantly enhance productivity and overall operational efficiency. By prioritizing innovation in equipment maintenance and choosing high-quality materials, businesses can streamline their processes and reduce costs in the long term. In conclusion, as the global marketplace continues to evolve, companies that embrace innovative practices and partner with dependable suppliers will remain competitive. Chengdu Zhixin Refractory Technology Co., Ltd. stands ready to support your operational needs with cutting-edge solutions that drive performance, safety, and sustainability in your symons cone crushers. By following these tips, you can ensure your equipment not only meets the demands of 2025 but also sets a benchmark in the industry.

10 Essential Tips For Symons Cone Crusher Head Ball in 2025 Where Service Meets Innovation

| Tip Number | Tip Description | Importance Level | Implementation Year |

|---|---|---|---|

| 1 | Regular maintenance checks | High | 2025 |

| 2 | Invest in high-quality materials | Medium | 2025 |

| 3 | Use innovative technology for monitoring | High | 2025 |

| 4 | Optimize crusher settings for efficiency | High | 2025 |

| 5 | Train personnel on equipment handling | Medium | 2025 |

| 6 | Implement smart automation systems | High | 2025 |

| 7 | Monitor wear & tear regularly | High | 2025 |

| 8 | Create a feedback loop for improvements | Medium | 2025 |

| 9 | Regularly update software systems | Medium | 2025 |

| 10 | Stay informed about industry trends | Low | 2025 |

Reasons to Choose Symons Cone Crusher Head Ball Where Innovation Meets 2025 Where Service Meets Innovation

J

Jessica Wilson

The product is fantastic! I appreciate how attentive the support staff was with my inquiries.

15 June 2025

C

Christopher Anderson

Very satisfied with my purchase! The customer service team displayed exceptional professionalism.

01 June 2025

J

Jack Young

Quality and service were both excellent. The team was very professional and knowledgeable.

09 May 2025

O

Oliver Collins

I am very impressed! The quality is unmatched and the customer care team was very informative.

21 May 2025

O

Olivia Green

Great quality! Their support services are professional and clearly customer-oriented.

05 July 2025

B

Brody Allen

The craftsmanship is top-tier. The support team after the purchase was incredibly helpful.

24 June 2025