Wholesale Telsmith Cone Crusher Concave and Mantle - Quality Exporter & Factory Supplies

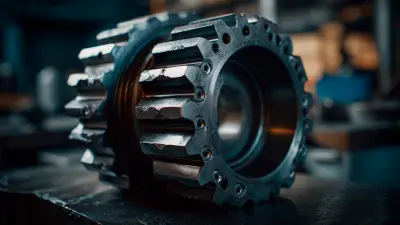

Engineered for exceptional performance, the Telsmith Cone Crusher Concave and Mantle from Chengdu Zhixin Refractory Technology Co., Ltd. are essential components that enhance the durability and efficiency of crushing operations. Made from high-quality materials, these parts are designed to withstand extreme conditions, ensuring a prolonged service life and reduced maintenance costs. The concave and mantle work seamlessly together to provide consistent crushing results, efficiently reducing large rocks to manageable sizes while maximizing output. Their precision design fosters optimal material flow and minimizes wear, resulting in increased productivity. Suitable for a variety of industries, including mining and construction, these Telsmith Cone Crusher components are backed by a commitment to innovation and exceptional customer service, guaranteeing products that meet the highest quality and reliability standards. Trust Chengdu Zhixin Refractory Technology Co., Ltd. to enhance your crushing performance and operational efficiency.Advantages Explained Telsmith Cone Crusher Concave And Mantle For the Current Year Service Backed by Expertise

In today's competitive mining and aggregates industry, choosing the right equipment is crucial for maximizing operational efficiency and minimizing downtime. One standout option is the Telsmith cone crusher, renowned for its robust performance and exceptional reliability. A key feature of this machinery is the concave and mantle, which play a pivotal role in the crushing process. These components are designed to withstand high-impact forces while providing optimal material flow and uniform size distribution. At Chengdu Zhixin Refractory Technology Co., Ltd., we leverage our expertise in producing special wear-resistant and high-temperature resistant materials to manufacture high-quality concaves and mantles. Our components are engineered with precision using advanced high manganese steel, ensuring extended service life and superior performance under extreme conditions. This translates into reduced maintenance costs and increased productivity, making our products a valuable investment for global buyers looking to enhance their operations. Backed by over a decade of experience and a commitment to innovation, we offer customized solutions that meet the unique demands of our clients. By partnering with us, you can access industry-leading technology and unparalleled support, ensuring your Telsmith cone crushers operate at peak efficiency throughout the year. Embrace the advantages of our expertly crafted concave and mantle to drive your business forward.

Advantages Explained: Telsmith Cone Crusher Concave And Mantle For the Current Year Service Backed by Expertise

| Feature | Advantages | Expert Insight |

|---|---|---|

| Concave Design | Improved material throughput and reduced wear. | Expert knowledge on optimal profiles enhances performance. |

| Mantle Durability | Longer service life leading to decreased maintenance costs. | Material selection based on years of research ensures longevity. |

| Ease of Replacement | Reduced downtime during maintenance operations. | Designed for quick and straightforward installation. |

| Custom Profiles | Tailored solutions for specific crushing applications. | Analysis of material properties leads to optimized designs. |

| Heat Treatment | Enhances hardness and impact resistance. | Expert understanding of metallurgical processes is key. |

The Secret to Telsmith Cone Crusher Concave And Mantle More Than a Supplier - A Partner in 2025

L

Linda Rodriguez

I’m impressed by the professionalism of the customer service staff. They provided excellent guidance and support post-purchase.

04 June 2025

L

Lucas Peterson

Quality is exceptional, and the after-sales service team was a pleasure to work with.

01 June 2025

A

Avery Adams

Impressive quality! The after-sales staff knew their stuff and were a great help.

30 June 2025

E

Eva Sanchez

The product is of great quality! The customer service team was very knowledgeable.

28 June 2025

K

Kyle Evans

I am very pleased with my purchase! Their supportive staff made all the difference.

17 June 2025

C

Christian Reed

Extremely satisfied! The after-sales support exceeded my expectations completely.

04 July 2025